Shell fabric manufacturing technology for improving stripping strength of high-denier gluing shell fabric

A technology for peeling strength and laminating fabrics, which is applied in the field of fabric manufacturing technology, can solve the problems of reducing the hand feeling and waterproof and moisture-permeable effect, changing the style and appearance of fabrics, and insufficient flatness of the fabric surface, so as to ensure the hand-feel, waterproof and moisture-permeable, Improve the peel strength and save the effect of calendering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

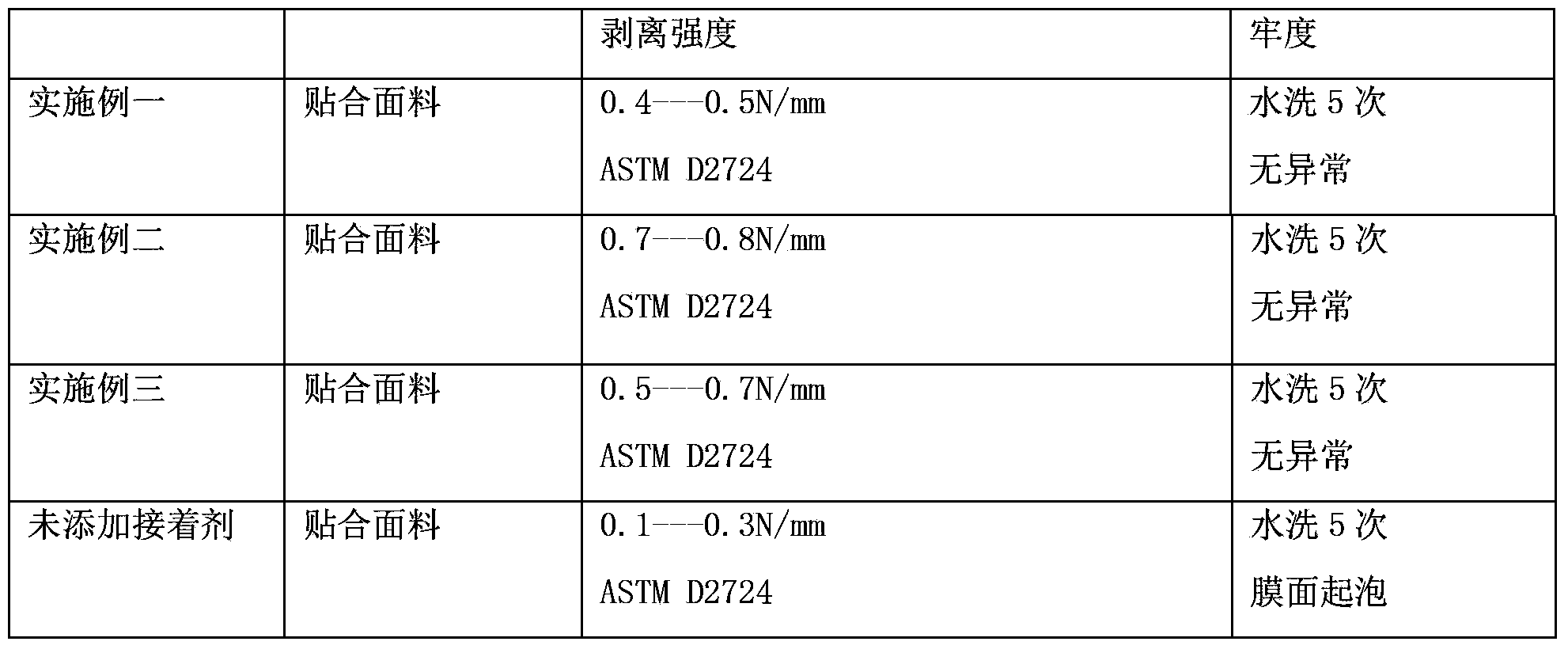

Examples

Embodiment 1

[0023] A fabric manufacturing process for improving the peel strength of high-denier laminated fabrics, the high-denier fabric is a fabric above 300D, and the fabric manufacturing process includes:

[0024] A. Glue compounding, the top glue raw materials and bottom glue raw materials are mixed and configured into top glue and bottom glue respectively, wherein the ratio of each component of the bottom glue includes: 100 parts by weight of polyurethane resin, 20 parts by weight of bottom glue solvent, 1 part by weight of Bridging agent, 5 parts by weight of one-component moisture-reactive adhesive, the appearance is a transparent mist viscous body, the solid content is 70-80%; the primer solvent is toluene, dimethylformamide, butanone One of them, the bridging agent is selected from isocyanate. The configuration process of the primer is as follows:

[0025] 1). Add the primer solvent into the empty bucket, and turn on the agitator to control the speed at 400rpm;

[0026] 2). ...

Embodiment 2

[0034] A fabric manufacturing process for improving the peel strength of high-denier laminated fabrics, the high-denier fabric is a fabric above 300D, and the fabric manufacturing process includes:

[0035] A. Glue compounding, the top glue raw materials and bottom glue raw materials are mixed and configured into top glue and bottom glue respectively, wherein the ratio of each component of the bottom glue includes: 100 parts by weight of polyurethane resin, 60 parts by weight of bottom glue solvent, 7 parts by weight of Bridging agent, 15 parts by weight of one-component moisture-reactive adhesive, 3 parts by weight of bridging accelerator, the appearance is a transparent mist viscous body, and the solid content is 70-80%; the primer solvent is toluene, Any two of methyl formamide and methyl ethyl ketone, and the bridging agent is selected from isocyanate. The configuration process of the primer is as follows:

[0036] 1). Add the primer solvent into the empty bucket, and tu...

Embodiment 3

[0045] A fabric manufacturing process for improving the peel strength of high-denier laminated fabrics, the high-denier fabric is a fabric above 300D, and the fabric manufacturing process includes:

[0046] A. Glue compounding, the top glue raw materials and bottom glue raw materials are mixed and configured into top glue and bottom glue respectively, wherein the ratio of each component of the bottom glue includes: 100 parts by weight of polyurethane resin, 40 parts by weight of bottom glue solvent, 5 parts by weight of Bridging agent, 10 parts by weight of one-component moisture-reactive adhesive, 2 parts by weight of bridging accelerator, the appearance is a transparent micro-mist viscous body, and the solid content is 70-80%; the primer solvent is toluene, two The three of methyl formamide and methyl ethyl ketone are mixed, the ratio of each component is 5:10:5 by weight, and the bridging agent is selected from isocyanate. The configuration process of the primer is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com