Free-cutting high-hardness austenite nonmagnetic die steel and manufacturing method thereof

A technology of non-magnetic mold and manufacturing method, which is applied in the field of easy-cutting high-hardness austenitic non-magnetic mold steel and its manufacturing field, can solve problems such as difficulties, and achieve the effects of convenient processing, excellent easy-cutting performance, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

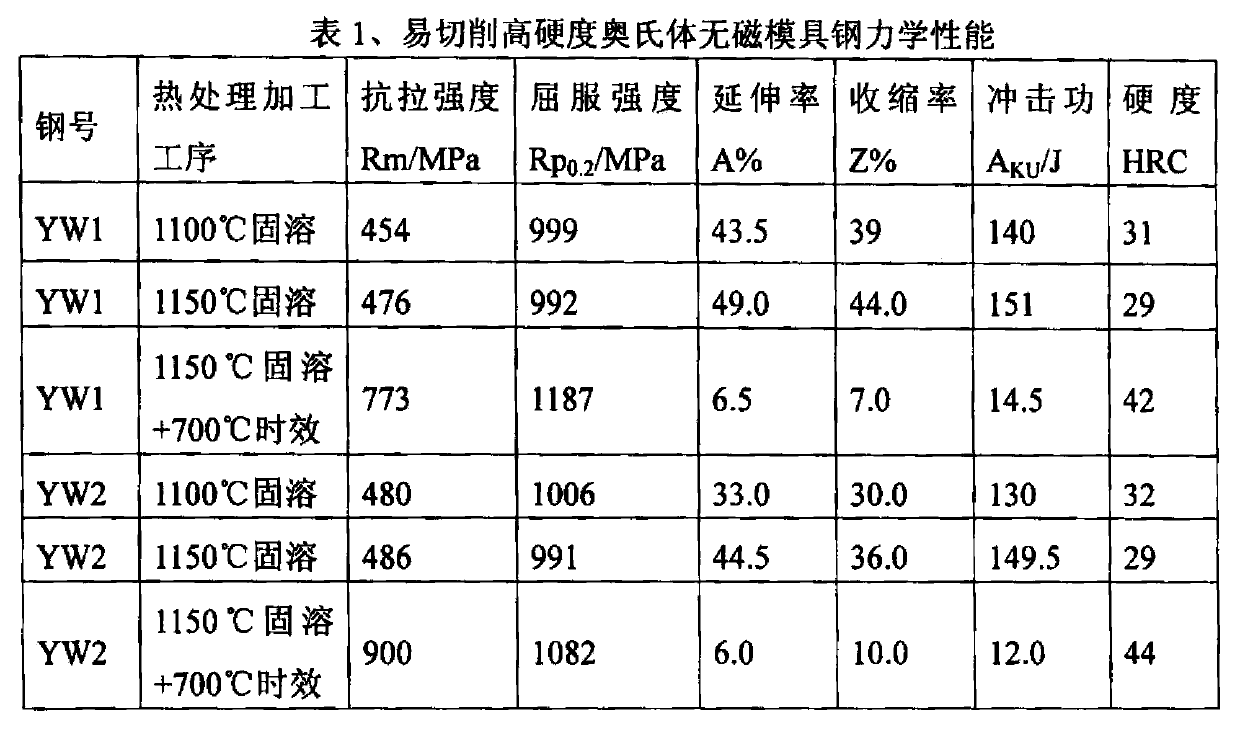

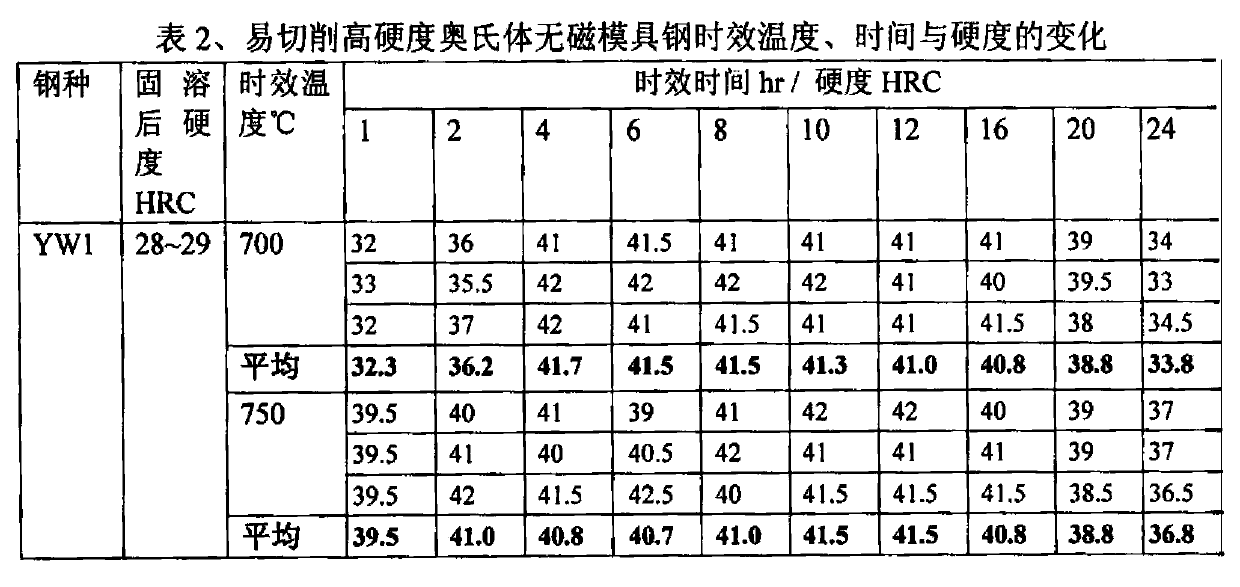

[0032] A free-cutting high-hardness austenitic non-magnetic die steel, represented by YW1, the chemical elements of the die steel by weight percentage are: C0.54%, Si0.43%, Mn15.79%, Cr5.05%, V1 .60%, easy cutting elements 0.37%, the balance is Fe. Among them, the easy cutting elements are Se0.02%, Sn0.20%, Cu0.15%.

[0033] The manufacturing method of the above-mentioned high-hardness austenitic non-magnetic free-cutting die steel is as follows: all kinds of charge materials such as pure iron, ferromanganese, ferrochromium, ferrovanadium and free-cutting elements containing the above-mentioned components are smelted through a non-vacuum induction furnace, and the smelting The temperature is 1450°C, then electroslag remelting, then forging at 1150°C, then solid solution at 1100-1150°C for 1-2 hours, water cooling to room temperature; then aging at 700-750°C for 4-6 hours to obtain high hardness Austenitic non-magnetic free-cutting die steel is processed into required parts, w...

Embodiment 2

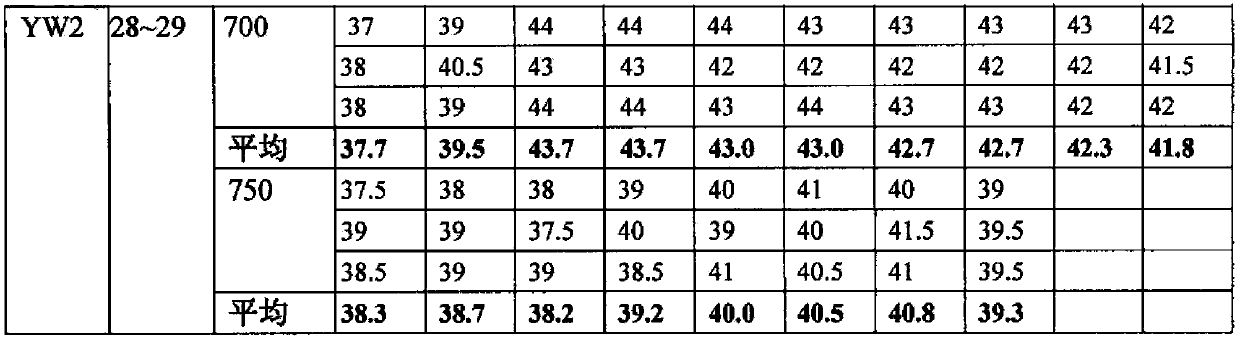

[0035] A free-cutting high-hardness austenitic non-magnetic die steel, represented by YW2, the chemical elements of the die steel by weight percentage are: C0.47%, Si0.48%, Mn13.57%, Cr5.05%, V1 .77%, easy cutting elements 0.48%, and the balance is Fe. Among them, the easy cutting elements are Se0.03%, Sn0.25%, Cu0.20%.

[0036] The manufacturing method of the above-mentioned free-cutting high-hardness austenitic non-magnetic die steel is as follows: all kinds of furnace materials including pure iron, ferromanganese, ferrochrome, ferrovanadium and one or more free-cutting elements are subjected to non-vacuum induction Furnace melting at 1400°C, electroslag remelting, forging at 1130°C, solid solution at 1100-1150°C for 1-2 hours, water cooling to room temperature; aging at 700-750°C for 4- 6h, the free-cutting high-hardness austenitic non-magnetic die steel was obtained, and processed into the required parts, which met the product design and use requirements.

[0037] The fr...

Embodiment 4

[0066] A free-cutting high-hardness austenitic non-magnetic die steel, the die steel is composed of the following chemical elements in percentage by weight: C0.45%, Si0.30%, Mn16.00%, Cr6.00%, V2. 50%, easy cutting elements 0.30%, and the balance is Fe. Among them, the easy cutting elements are Se0.05% and Sn0.25%.

[0067] Free-cutting high-hardness austenitic non-magnetic die steel has the following mechanical properties: use hardness ≥ HRC40, tool wear during machining is less than 30% of similar steel without easy-cutting elements, and relative magnetic permeability ≤ 1.050.

[0068] A method for manufacturing free-cutting high-hardness austenitic non-magnetic die steel, the method comprising the following steps:

[0069] (1) According to the ratio of mold steel, the charge is smelted in a non-vacuum induction furnace according to the process requirements. The melting temperature is 1450°C. Metal;

[0070] (2) After the treatment in step (1), carry out electroslag remel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com