Low-aluminum low-magnesium zinc-aluminum-magnesium plated steel plate and method for producing same

A coated steel plate and production method technology, applied in coating, hot-dip coating process, metal material coating process, etc., can solve the problems of increased process complexity, increased cost, and decreased corrosion resistance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

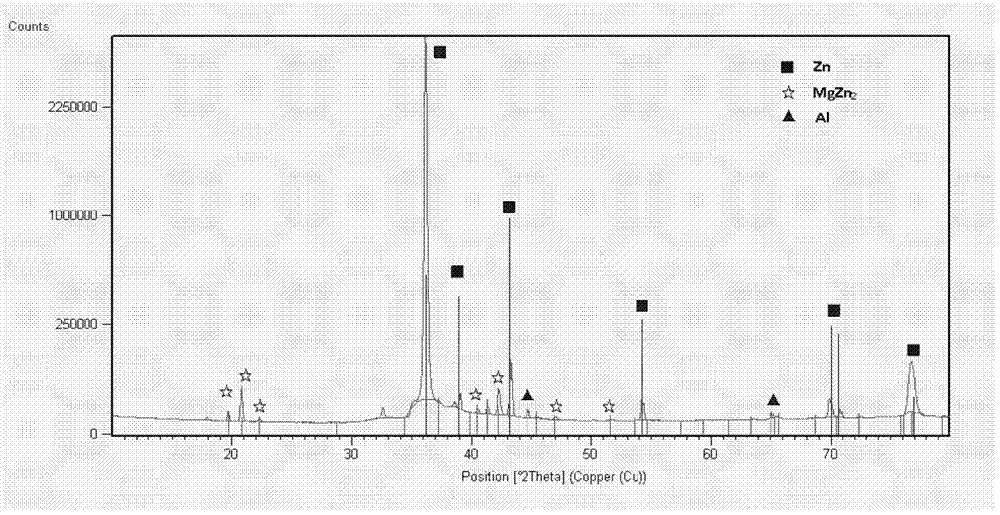

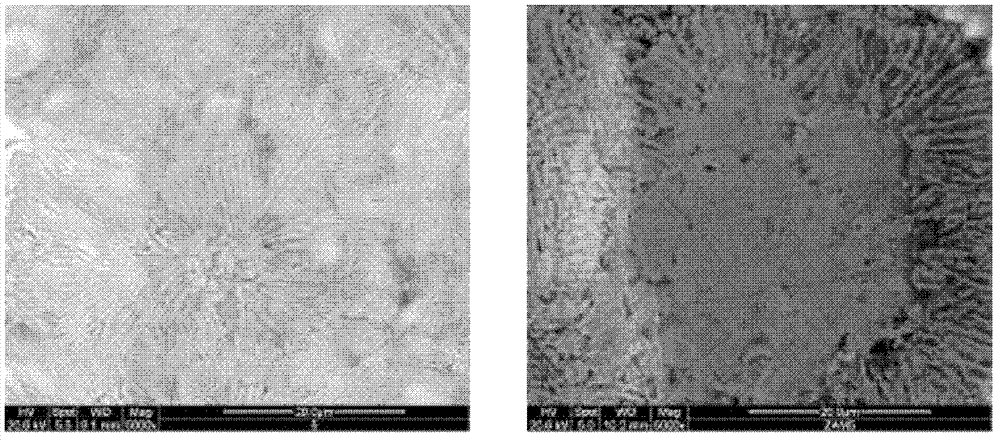

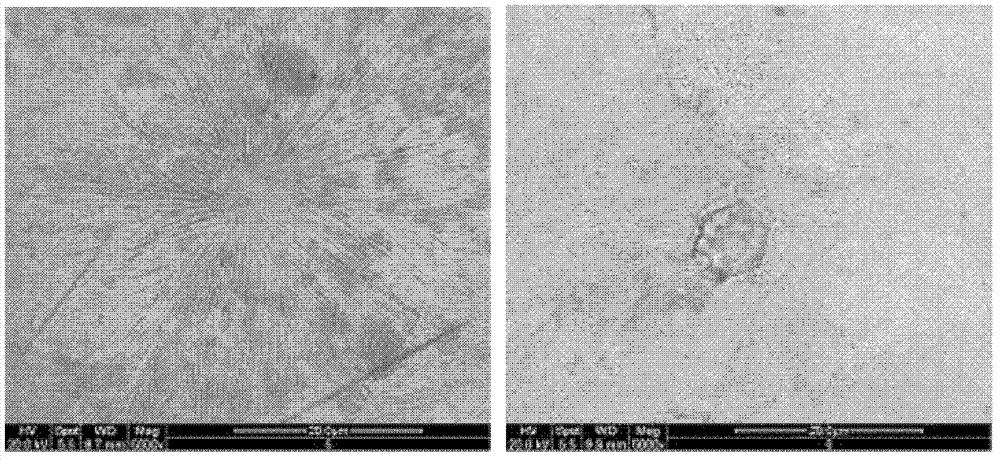

Image

Examples

Embodiment Construction

[0023] The chilled steel strip is continuously annealed and hot-dip galvanized aluminum-magnesium alloy in the continuous hot-dip galvanizing line to produce low-aluminum and low-magnesium zinc-aluminum-magnesium coated steel sheets. The main process parameters are shown in Table 1, and the composition of the plating solution is shown in Table 2. See Table 3, and see Table 4 for properties of coated steel sheets. No. 1 in Table 1 corresponds to No. 1 to 6 in Table 2; No. 2 in Table 1 corresponds to No. 7 to 12 in Table 2; No. 3 in Table 1 corresponds to No. 13 to 18 in Table 2; No. 4 in Table 1 Corresponds to serial numbers 19-24 in Table 2; serial number 5 in Table 1 corresponds to serial numbers 25-30 in Table 2.

[0024] Table 1 main process parameters

[0025]

[0026] Table 2 Chemical Composition of Plating Solution

[0027] serial number

Al,%

Mg, %

Al / Mg

Ti,%

RE,%

1

1.0

1.0

1.0

2

1.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com