Multi-energy, low-carbon, energy-saving and environment-friendly synchronous one-stroke anti-detonation internal combustion engine

An energy-saving, environmentally friendly, multi-energy technology, applied in mechanical equipment, machines/engines, etc., can solve the problems of large exhaust gas pollution, complex structure, low efficiency, etc., to achieve high mechanical efficiency, expand the field of use, and increase power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Implementation example 1:

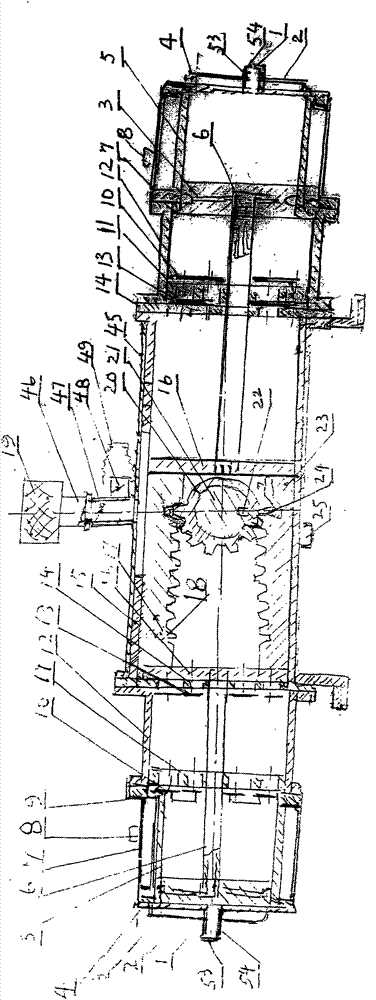

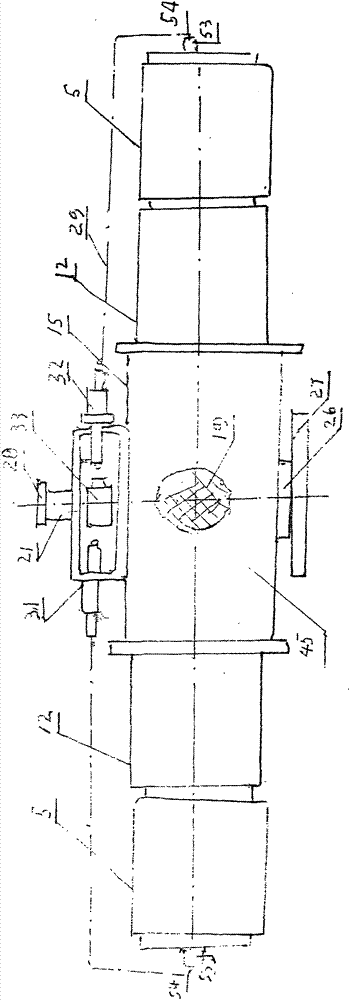

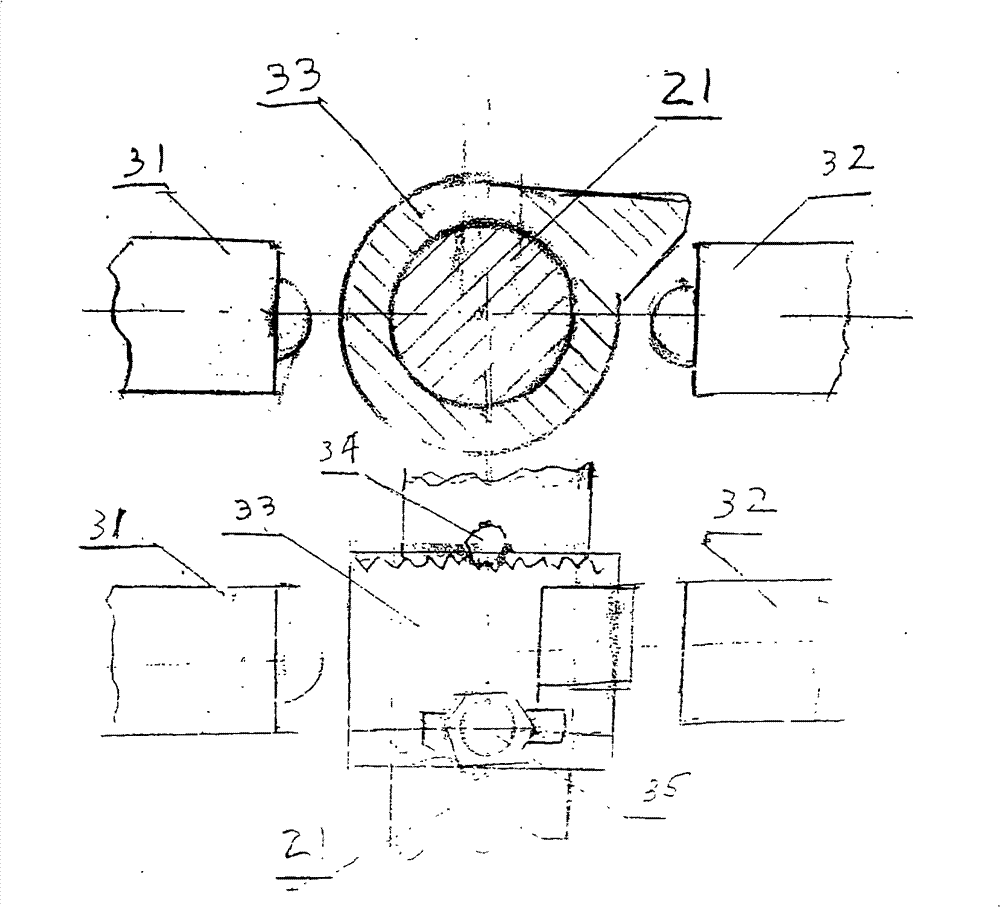

[0025] Such as figure 1 As shown, it is a schematic diagram of a multi-energy, low-carbon, energy-saving and environmentally friendly synchronous one-stroke counter-explosion internal combustion engine. figure 2 Its top view. The names and numbers of its parts are as follows: pre-combustion chamber 1, cylinder head 2, main cylinder with oil circuit piston 3, decompression device 4, main cylinder 5, cylindrical piston rod with oil circuit 6, cooling water jacket 7, water inlet pipe 8, Exhaust hole 9, scavenging valve 10, intake scavenging piston 11, intake scavenging cylinder 12, intake valve 13, intake partition 14, fuselage 15, upper and lower rack connecting plate 16, upper rack 17 , multi-tube elastic teeth 18, air filter device 19, shaped like a half-side gear 20, spindle assembly 21, spindle pin 22, lower rack 23, sheet short elastic teeth 24, oil drain bolt 25, spindle bearing 26, spindle flywheel 27, Main shaft output flange 28, oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com