Assembling jet device

An ejector and assembled technology, applied in the field of ejectors, can solve the problems of increasing the structural complexity of the ejector, increasing the difficulty of processing, and non-adjustable nozzles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

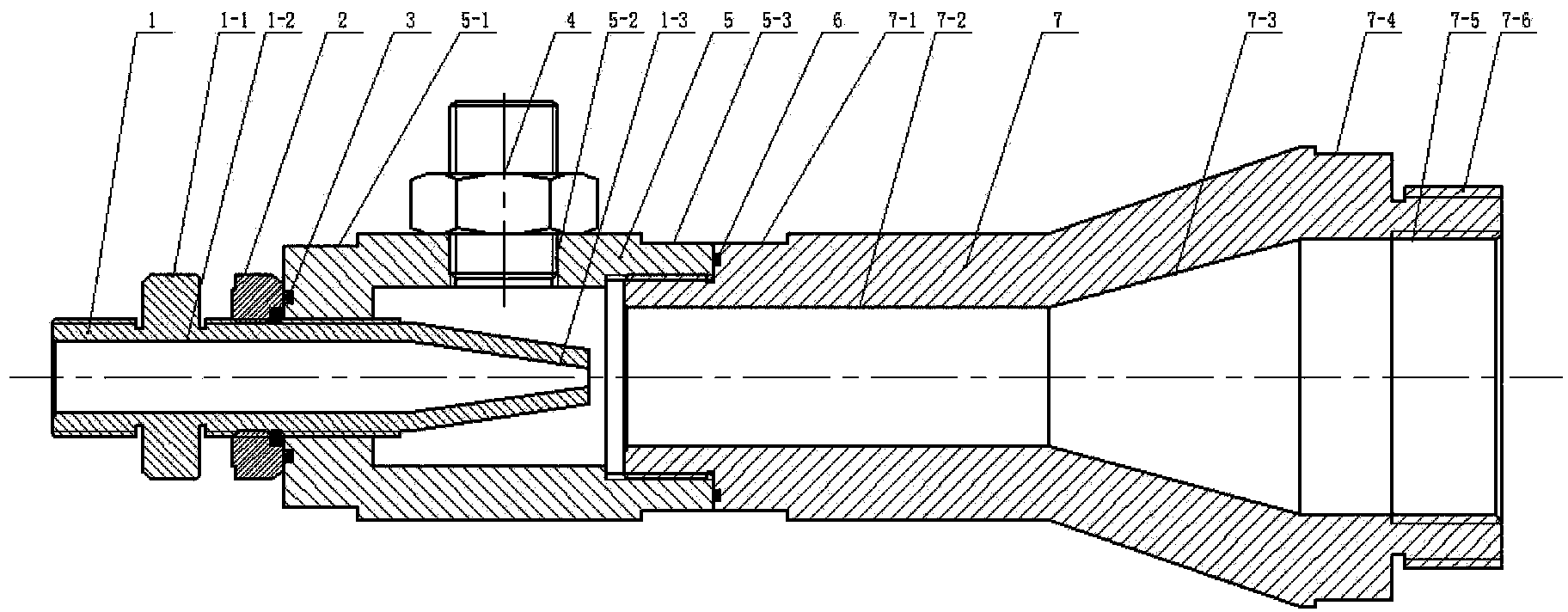

[0012] See figure 1 , The present invention includes a nozzle 1, a suction cavity 5 and a spray cavity 7. The nozzle 1 is composed of a nozzle bayonet 1-1 of an external hexagon wrench, a nozzle throat 1-2 with external threads, and a cone-shaped nozzle 1-3. The cavity 5 is composed of the inlet of the inner suction cavity, the outlet wrench bayonet 5-1, 5-3 and the internal threaded interface 5-2 between the two suction cavity wrench bayonet. The spray cavity 7 is composed of an external thread Jet cavity wrench bayonet 7-1, annular cavity 7-2, flared jet nozzle 7-3, jet cavity outlet wrench bayonet 7-4, internal thread interface 7-5 and external thread interface 7-6, nozzle 1. The throat pipe 1-2 and the suction cavity inlet wrench bayonet 5-1 are threadedly connected, and an "O" sealing ring 3 for radial sealing is arranged between the two, and is locked by a nylon lock nut 2. Dead, the nylon lock nut 2 is axially sealed to prevent oil leakage and is used to adjust the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com