Optical measuring instrument temperature control method and device, and optical measuring instrument

A technology of temperature control equipment and optical measurement, applied in optical radiation measurement, scientific instruments, photometry, etc., to achieve high precision, comprehensive temperature control, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

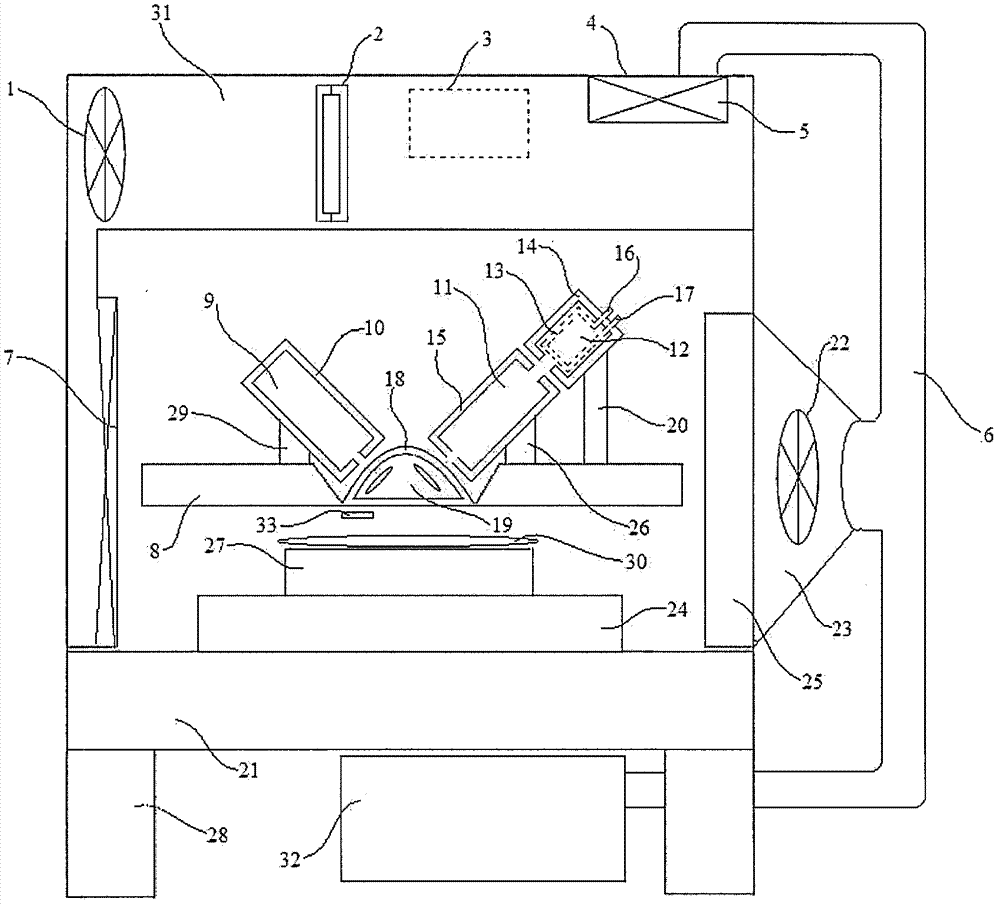

Method used

Image

Examples

specific Embodiment approach 1

[0061] In this embodiment, the first, second and fourth temperature control elements are realized by thermal insulation components, specifically:

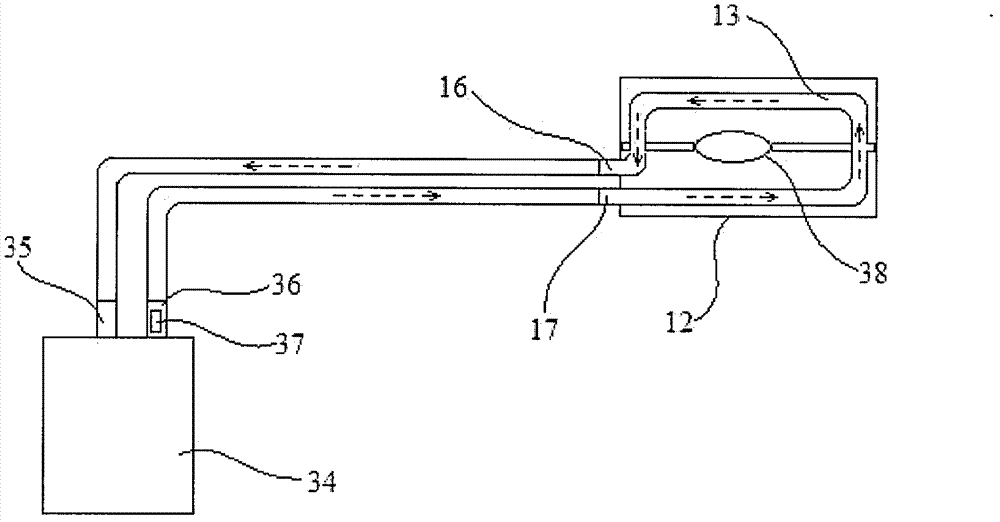

[0062] 1. Control of heat source and incident, outgoing and lens group modules

[0063] refer to figure 2 , in this system, the light source 38 buried in the light source module 12 is the largest heat source, in order to take away the heat generated by it, water pipes 13 are placed around it. The cold water flows out from the water outlet 36 of the chiller to the water inlet 17 of the light source module, and then flows through the pipe 13 to take away the heat from the light source to become hot water, and finally flows back to the water inlet 35 of the chiller through the water outlet 16 . The hot water is refrigerated by the chiller and then flows out from the water outlet by the pump, continuously circulating, thus taking away the heat. There are pumps, exhaust fans, water tanks, etc. inside the chiller, and the chiller is a...

specific Embodiment approach 2

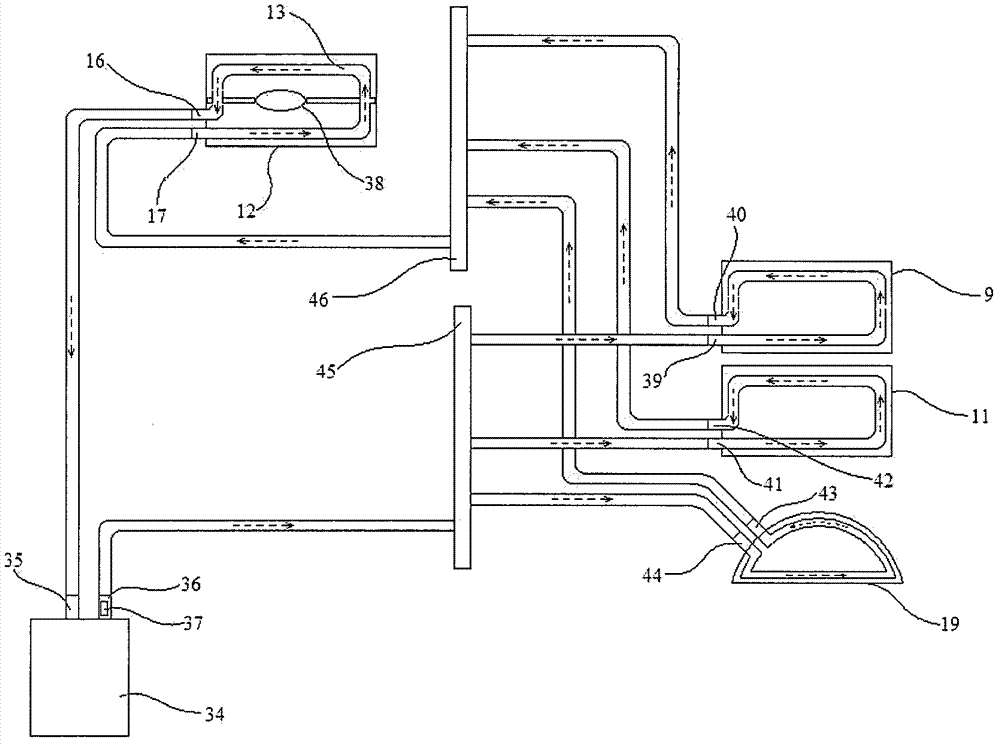

[0072] The system structure of Scheme 2 is the same as Scheme 1, and the ambient temperature control of the optical path space in the measurement area is also the same as Scheme 1. The difference is that in Scheme 1, the first, second and fourth temperature control elements are all wrapped with heat insulating materials to avoid being affected by heat; in this scheme, these temperature control elements are uniformly cooled by a water cooling device. module.

[0073] In a preferred embodiment, the first, second and fourth temperature control elements and the third temperature control element share a set of water-cooling pipelines. For the wiring diagram of the water-cooling pipelines, please refer to image 3 . Water pipes are laid inside the light source module 12, the incident module 11, the exit module 9 and the lens group module 19 for feeding cold water. Water pipes should try to wrap each module as much as possible. In the series-parallel design of pipelines, it is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com