Circular polarization light panel and making method thereof

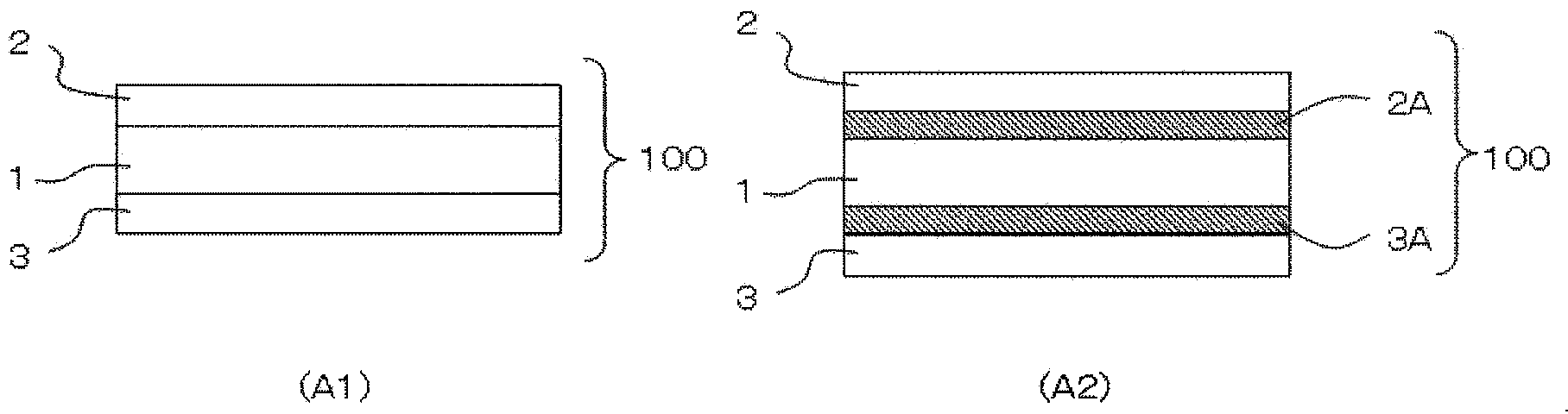

A technology of circularly polarized light and polarizing layer, applied in the field of circularly polarized light plate and its manufacturing, can solve the problems of thick total thickness of circularly polarized light plate, unsuitable for circularly polarized light plate, etc., and achieve the effect of excellent anti-reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

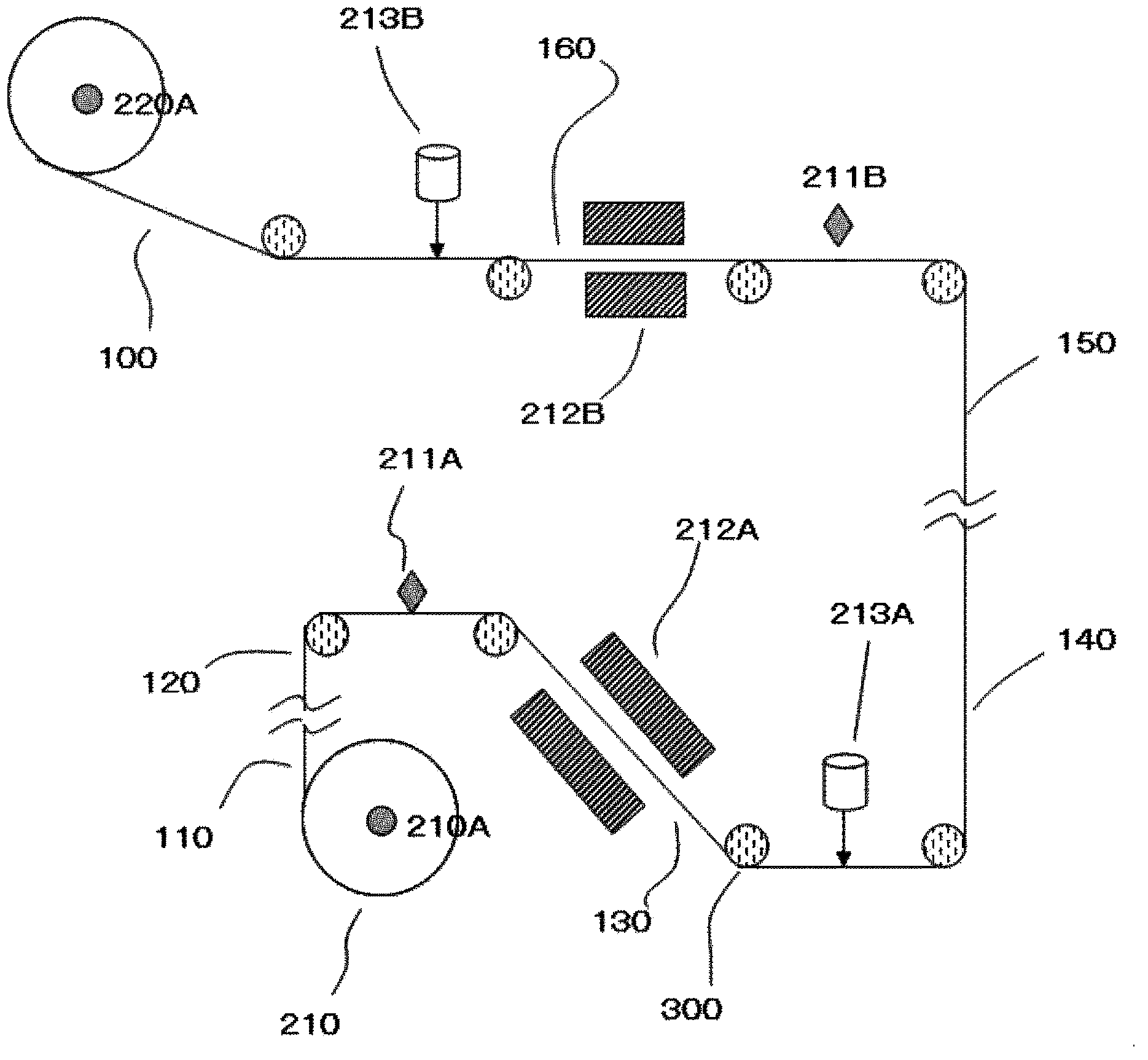

Method used

Image

Examples

Embodiment 1

[0284] (Preparation of composition (1) for liquid crystal retardation layer formation)

[0285] The following components were mixed, and it stirred at 80 degreeC for 1 hour, and obtained the composition (1) for liquid crystal retardation layer formation.

[0286] Polymeric liquid crystal compound; trade name LC-242 manufactured by BASF Co., Ltd. 100 parts

[0287]

[0288] polymerization initiator;

[0289] 2-Methyl-1-[4-(methylthio)phenyl]-2-morpholinylpropan-1-one

[0290] (Irgacure (Irgacure) 907: Manufactured by Ciba Specialty Chemicals Co., Ltd.) 3 parts

[0291] Solvent; 250 parts of cyclopentanone

[0292] (Preparation of composition (1) for photo-alignment layer formation)

[0293] The following components were mixed, and it stirred at 80 degreeC for 1 hour, and obtained the composition (1) for photo-alignment layer formation.

[0294] Photo-alignment material; 5 parts

[0295]

[0296] Solvent; 95 parts of cyclopentanone

[0297] (Preparation of Polarizin...

Embodiment 2

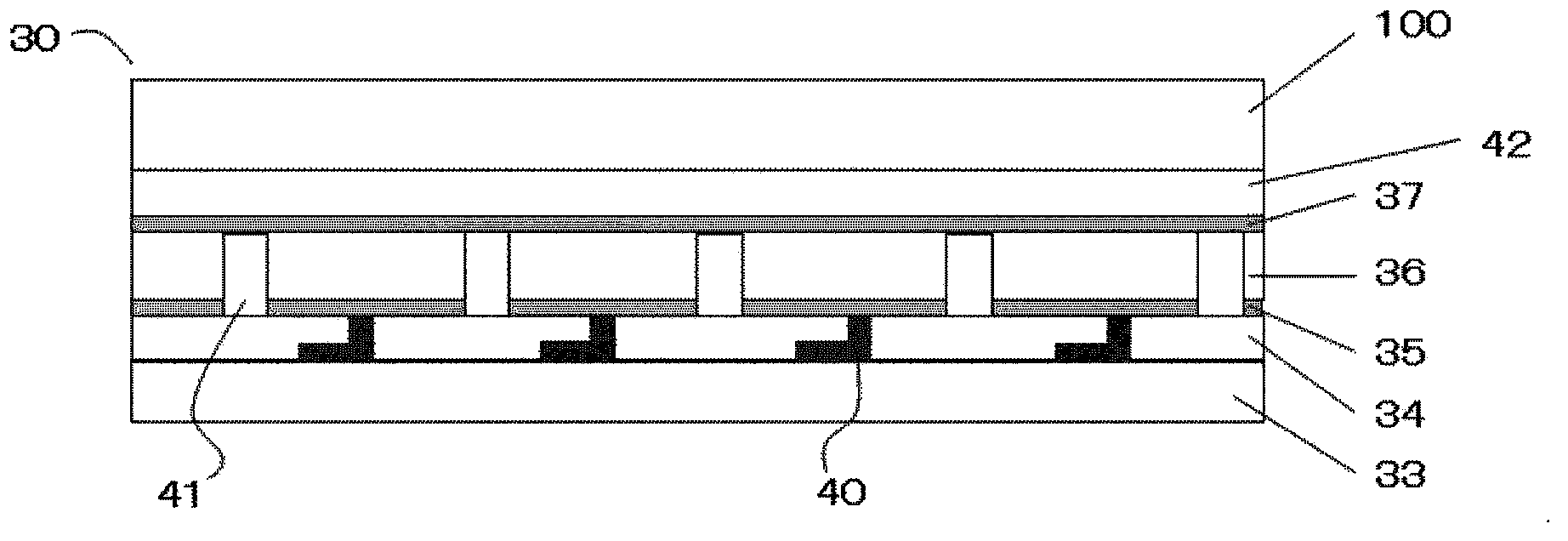

[0335] Same as in Example 1, a photo-alignment layer was formed on one surface of the retardation film (the polarization direction of polarized light UV was 60° relative to the slow axis of the retardation film), and a liquid crystal retardation layer was formed on the photo-alignment layer. Then, on the surface of the retardation film with liquid crystal retardation that is opposite to the surface of the liquid crystal retardation, form a photo-alignment layer (the polarization direction of the polarized light UV is 15° relative to the slow axis of the retardation film), where the photo-alignment A polarizing layer is further formed on the layer to make the circular polarizing plate (2).

[0336] The total thickness of the circular polarizing plate (2) was measured by a contact film thickness meter, and it was 46 μm.

[0337] Same as in Example 1, the circular polarizing plate (2) is bonded to the reflector using an adhesive, and the reflectance is measured. The light in the ...

reference example 1

[0342] An iodine-PVA polarizing plate (manufactured by Sumikaran Sumitomo Chemical Co., Ltd. with a thickness of 105 μm) as a polarizing plate was cut into small pieces of 100×100 mm, and the absorption axis was set at 0°. The 1 / 2 wavelength plate used in Example 1 was cut into 100 mm. For small pieces of ×100 mm, the slow axis was set at 15°, and the 1 / 4 wavelength plate used in Comparative Example 1 was cut into small pieces of 100×100 mm, and the slow axis was set at 75°. The sheets were laminated using an acrylic adhesive (film thickness 25 μm), and each film was made into a polarizing plate + 1 / 2 wavelength plate + 1 / 4 wavelength plate to obtain a circular polarizing plate (4).

[0343] Same as in Example 1, the circular polarizing plate (4) is bonded on the reflector using an adhesive, and the reflectance is measured. The light in the range of 400 to 700 nm, any wavelength is about 1 to 10%, and can be used in Sufficient anti-reflection properties are obtained throughout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com