Novel high-power LED light source and implementation method thereof

A LED light source, high-power technology, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems that the brightness and life of the product cannot be guaranteed, cannot be popularized and used, and the cost is high, and achieve good light effect, simple structure, and long life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

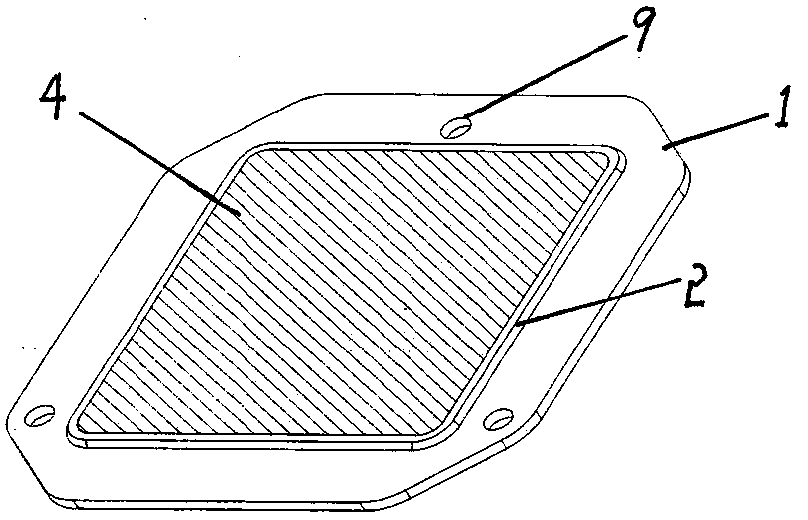

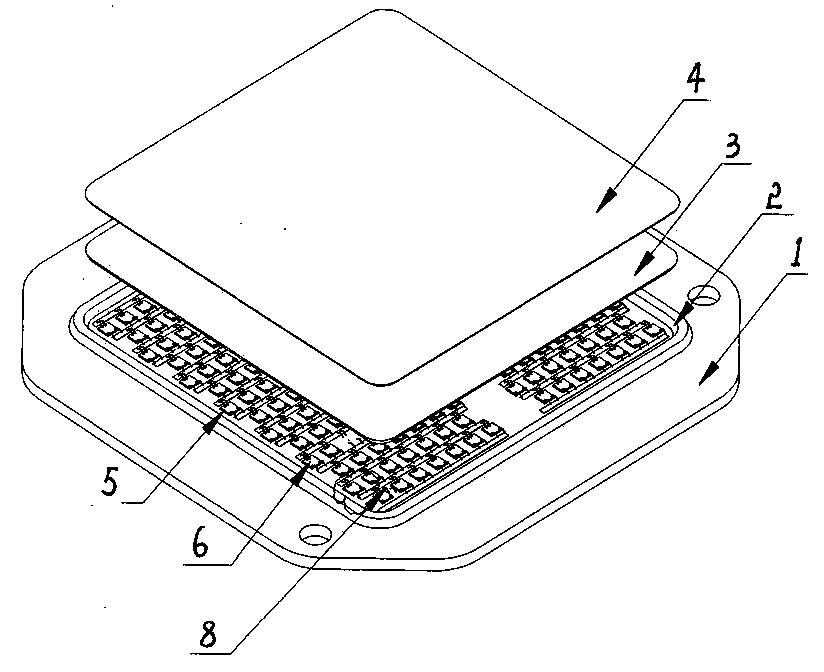

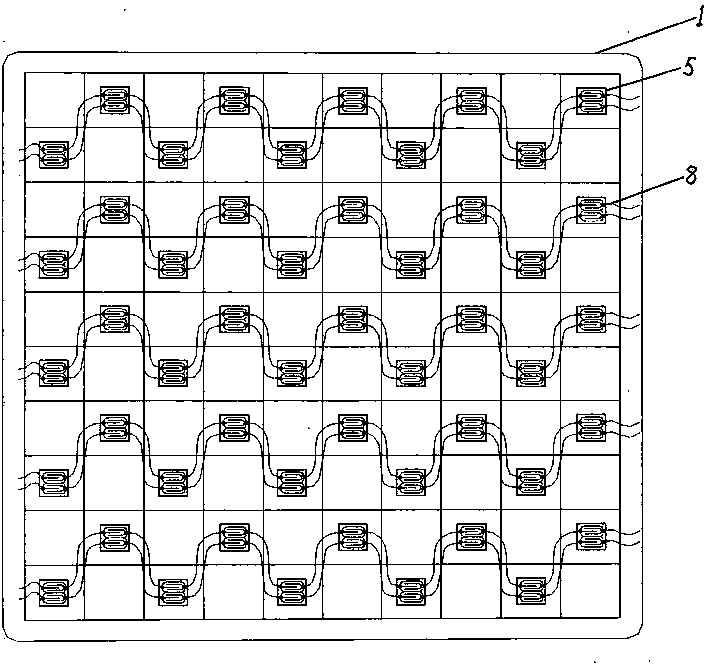

[0019] The invention consists of ceramic substrate (1), electronic dam glue (2), high-power LED chip (5), fluorescent glue (3), silica gel (4), bonding gold wire (8), high thermal conductivity silver paste (6) Composed of silver paste (7), the ceramic substrate (1) is in the form of a sheet, with mounting holes (9) arranged on its edge, tiny holes are evenly distributed on the ceramic substrate (1), and silver paste is poured into the tiny holes (7), the electronic dam glue (2) is set on the ceramic substrate (1), and forms a whole with the ceramic substrate (1); multiple high-power LED chips (5) are bonded to the ceramic substrate in a staggered arrangement Within the scope of the electronic dam glue (2) on (1), the power of a single LED is 1W; the bonding gold wire (8) has a wire diameter of 1.2mil, and is connected to the electrode of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com