Converter device used for performing driving control on electric vehicle

A drive control, electric vehicle technology, applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc., can solve the problem of increasing the size and cost of the driver, and reducing the efficiency of the converter. There is no disclosure or suggestion to solve the problem. Measures to solve this problem, etc., can reduce the distributed inductance of the busbar, improve the impact of short-term overload current, and be conducive to the effect of current sharing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical solutions of the present invention, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

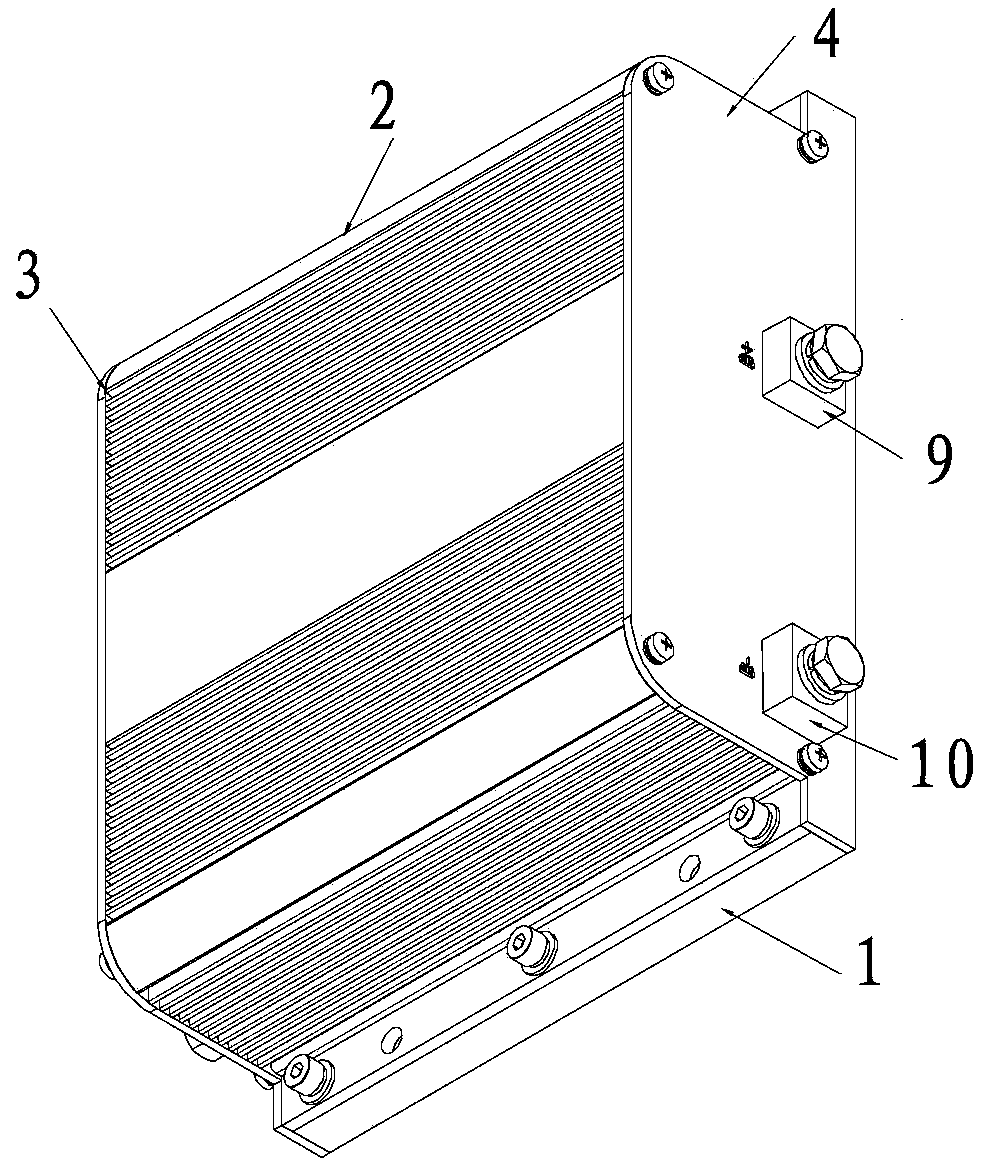

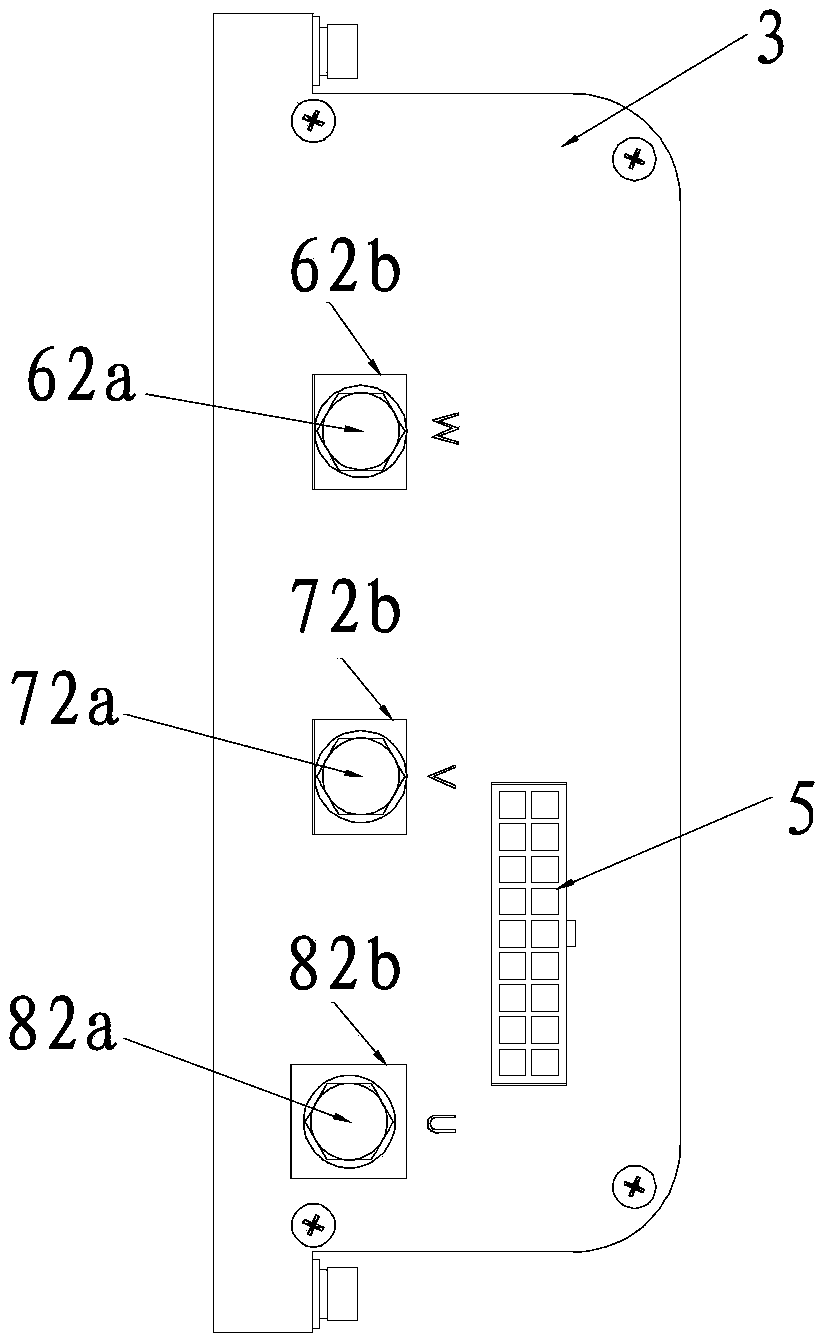

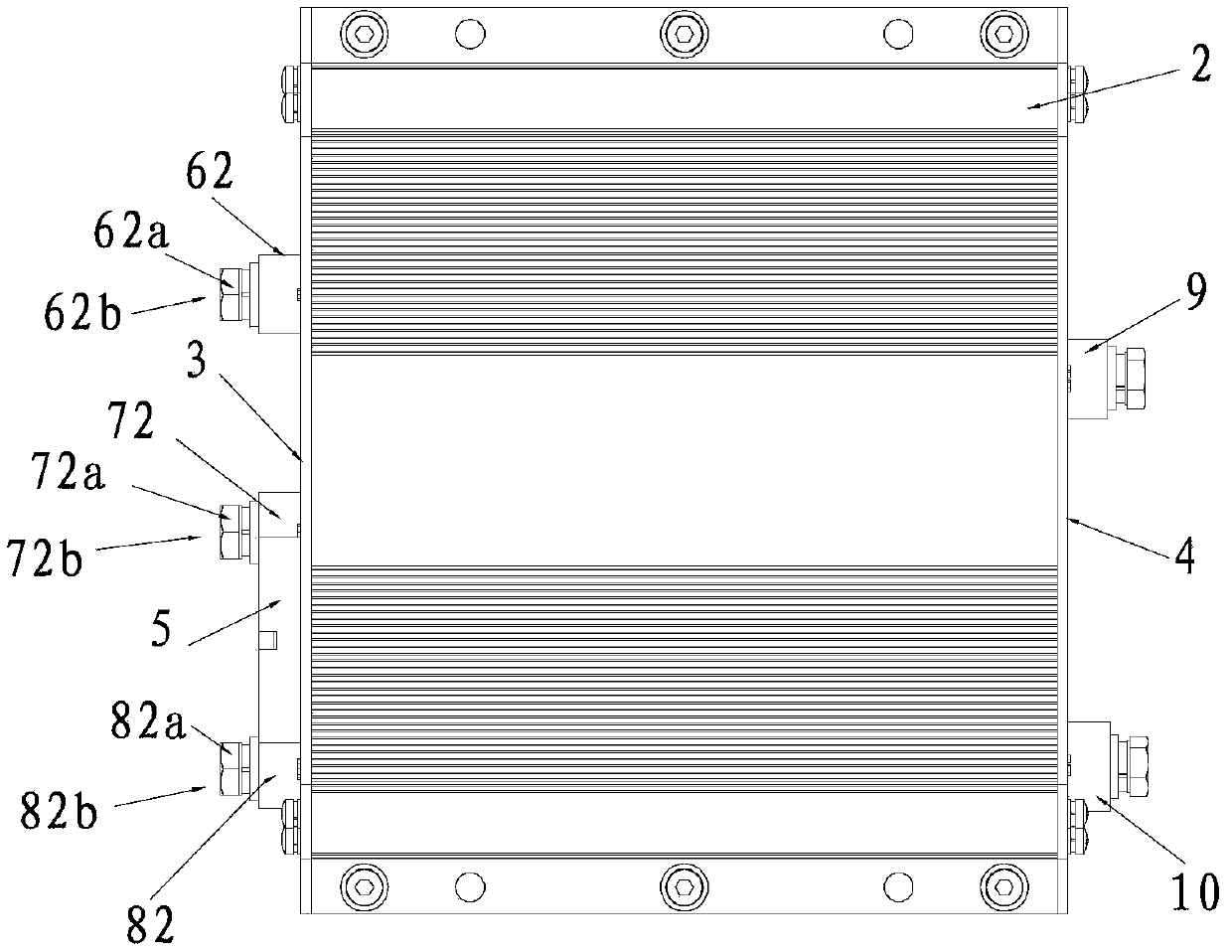

[0037] see Figure 1 to Figure 10, the converter device for electric vehicle driving control of the present invention comprises a cooling base plate 1, three bridge arms arranged in parallel on the cooling base plate 1, a positive pole terminal 9, a negative pole terminal 10, and a controller circuit board 11 and two current transformers 12a, 12b.

[0038] The cooling bottom plate 1 is connected to an aluminum shell, and three grooves 1a, 1b, and 1c are provided on the cooling bottom plate 1 at uniform intervals and transversely parallel from front to back; The U-shaped upper cover 2 and the left and right cover plates 3, 4 respectively fixed on the two sides of the upper cover 2 and the cooling bottom plate 1, wherein the front, middle and rear parts of the left cover plate 3 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com