Disc type iron-core-free permanent magnet synchronous motor controller for electric automobile hub

A permanent magnet synchronous motor, disc-type ironless technology, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of fast current rise, motor torque fluctuation, discontinuous torque, etc. Reduced torque ripple, improved dynamic performance, and good torque characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

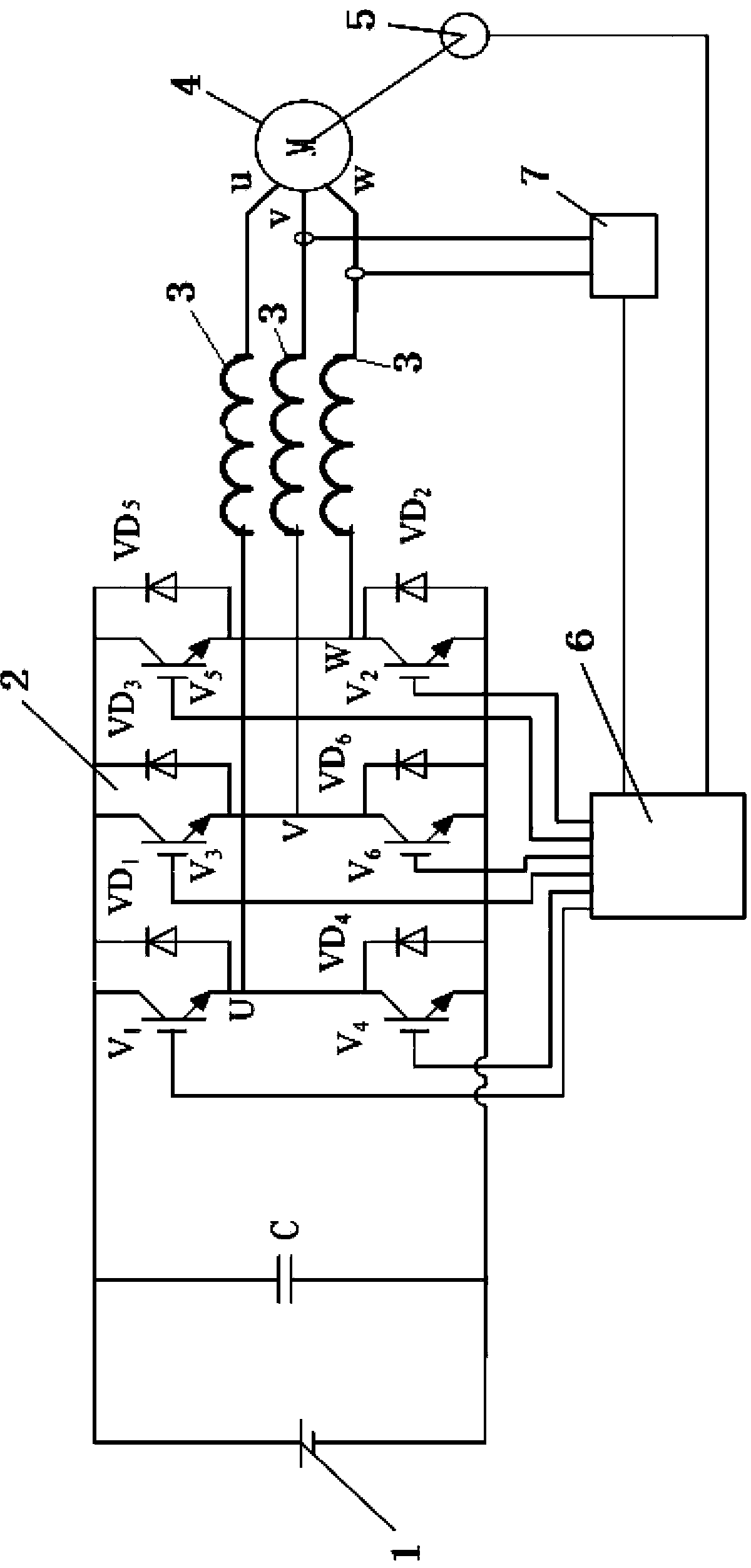

[0018] A disc-type coreless permanent magnet synchronous motor controller for an electric vehicle wheel hub according to the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

[0019] A disc-type coreless permanent magnet synchronous motor controller for an electric vehicle hub according to the present invention, the control system adopts a voltage-type inverter circuit, and a three-phase output terminal of the control system and a three-phase input terminal of the motor are respectively connected in series. Inductance, to increase the inductance value of the winding loop, so that the current in the motor stator winding can be continuous. According to the switching frequency of the voltage-type inverter circuit, the inductance value when the motor stator current continuous condition is satisfied is calculated, and the parameters of the inductance connected in series are obtained. The control circuit adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com