Technology for preparing fermented tea with combination of artificial inoculation and liquid state fermentation process

A technology of liquid fermentation and fermented tea, which is applied in the field of food processing, which can solve the problems of unautomatic control of the fermentation process, unstable product quality, and uncertain strains, so as to shorten the fermentation cycle, mellow and sweet taste, and controllable strains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

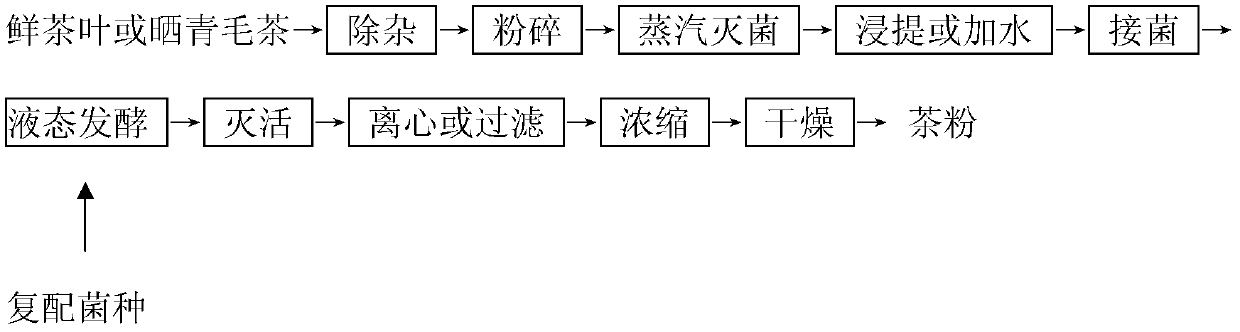

Method used

Image

Examples

Embodiment 1

[0049] Screening of dominant flora:

[0050] Using PCR-DGGE technology to analyze the dominant flora in the solid-state fermentation process of traditional Pu-erh tea, it was found that Penicillium vulgaris, Aspergillus niger, Candida rugosa, Bacillus coagulans and Brevibacterium were the dominant flora in the fermentation process of "Watui" ,

[0051] The screening method is as follows:

[0052] This method is to directly extract the total DNA from the Pu'er tea sample in the fermentation process, then perform PCR amplification, and then use DGGE (denaturing gradient gel electrophoresis) to separate the dominant bands. Each band represents a dominant microorganism. DNA sequencing was performed to confirm that the dominant species were Penicillium vulgaris, Aspergillus niger, Candida rugosa, Bacillus coagulans and Brevibacterium

Embodiment 2

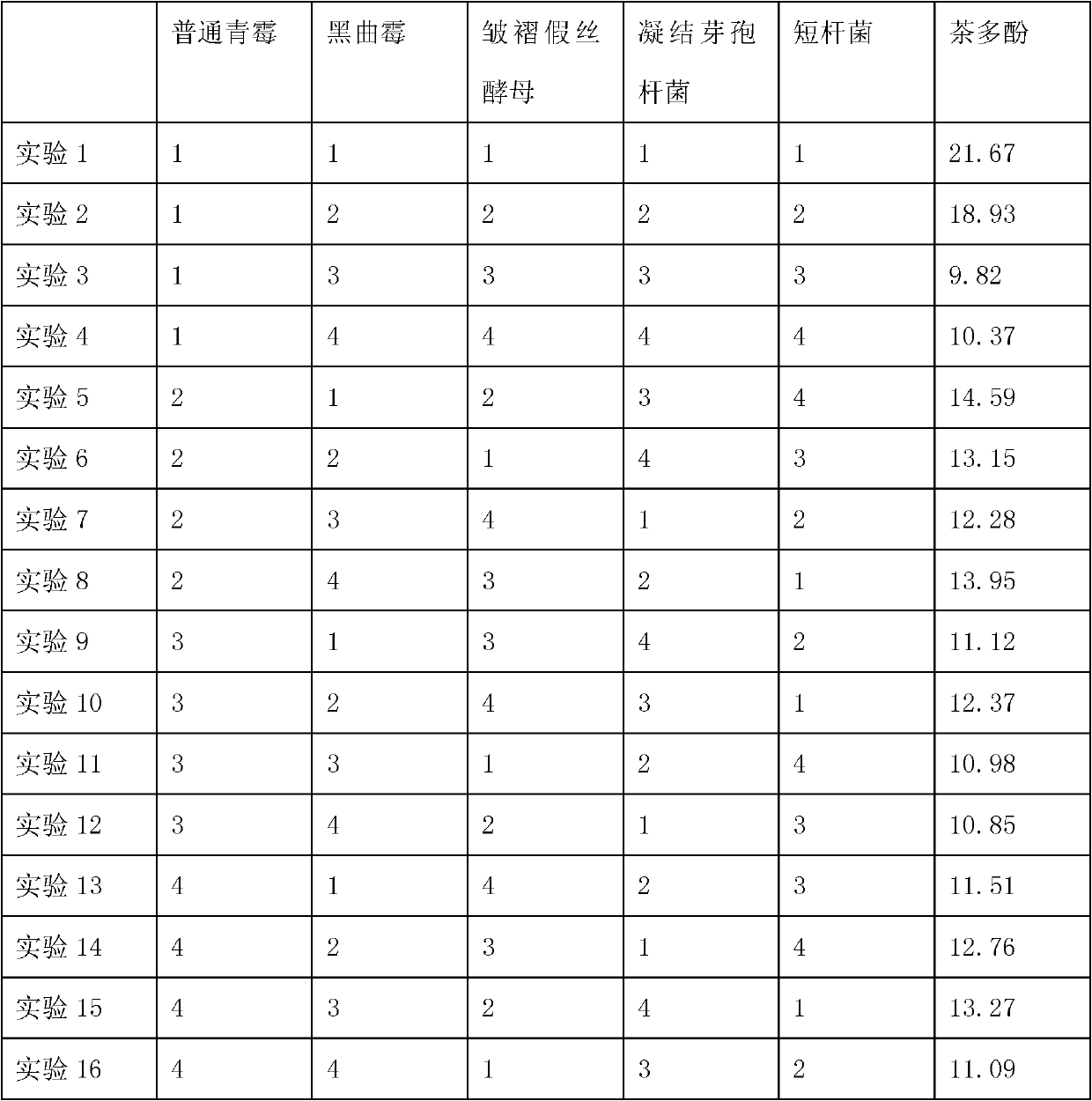

[0054] Proportion screening of optimal strains:

[0055] The screening method is as follows:

[0056] With the dominant bacterial species in embodiment 1, carry out orthogonal experiment according to the different ratio of weight, final determined

[0057] Weight ratio: Penicillium vulgaris: Aspergillus niger: Candida rugosa: Bacillus coagulans: Brevibacterium = 1: 1: 4: 4: 4 (based on the dry weight of the thallus) The effect of the mixed strain is excellent.

Embodiment 3

[0059] Screening of inoculum amount of bacteria:

[0060]The screening method is as follows:

[0061] According to different inoculum amounts of 0.1%, 0.5%, 1.0%, etc., the dominant strains are increased according to the gradient of 0.5%, until 10%, and fermented. The final inoculum amount is as follows:

[0062] The inoculation amount of bacteria is 0.1%~10%

[0063] The preferred inoculation amount is 0.5% to 2%.

[0064] A particularly preferred inoculation amount is 1-2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com