Large aluminum fin automatic cleaning device and method

A technology of automatic cleaning and fins, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of increased production costs, increased risks, unstable quality, etc., and achieve economical cleaning Cost, extended service life, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

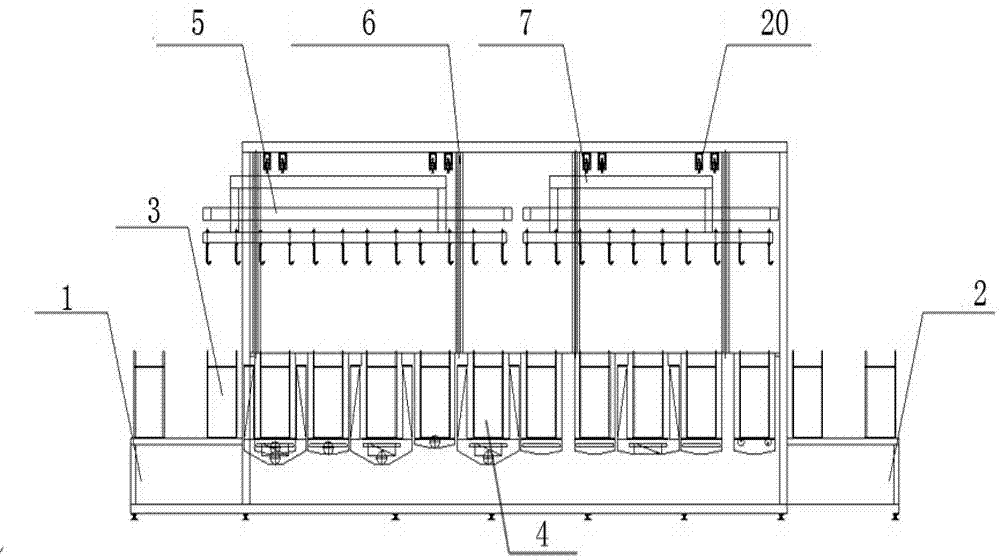

[0061] The aluminum fin automatic cleaning device of the present invention is composed of a set of loading and unloading platforms, a set of deionized pure water preparation system, a set of equipment lifting transmission system and a set of equipment production main line; The unloading table is equipped with a positioning bar at the loading position; the unloading position is equipped with photoelectric switch detection, and when there is a cleaning basket, the multi-arm manipulator will no longer drop to place the cleaning basket.

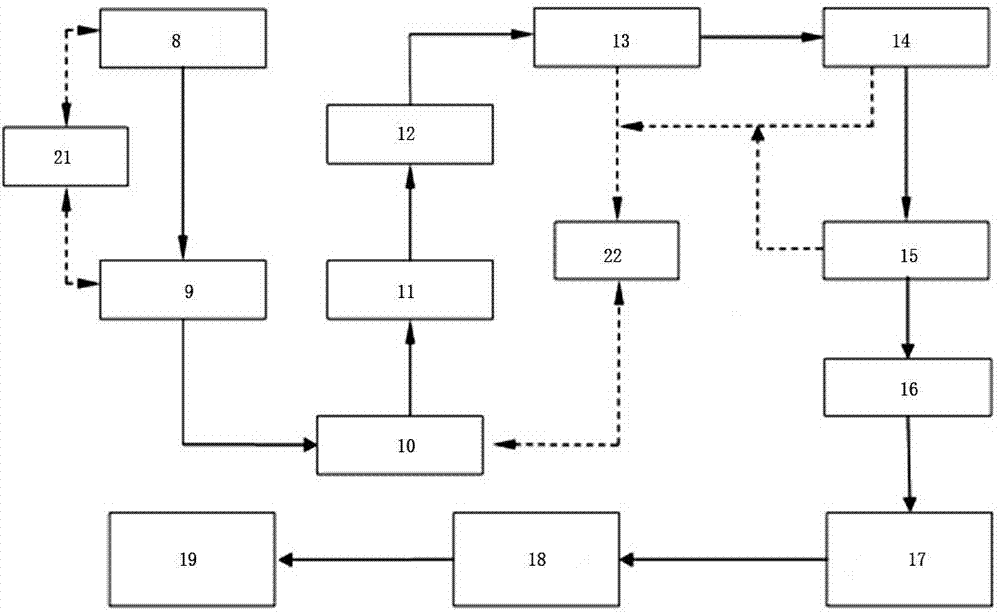

[0062] The deionized pure water preparation system The deionized pure water system consists of five subsystems: water intake, deionized water preparation, drainage, circulating water, and detection and control. Among them, the deionized water preparation subsystem is composed of raw water tank, deionized water raw water pump, mechanical filter, activated carbon filter, security filter, high pressure pump, reverse osmosis device, mixed bed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com