Boulardii active dry yeasts and production method thereof

A technology of active dry yeast and Brady's yeast, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve problems such as affecting the application effect, easy death of Brady's yeast cells, and inconvenient transportation , to achieve the effect of overcoming the difficulty of drying, low production cost and high live cell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

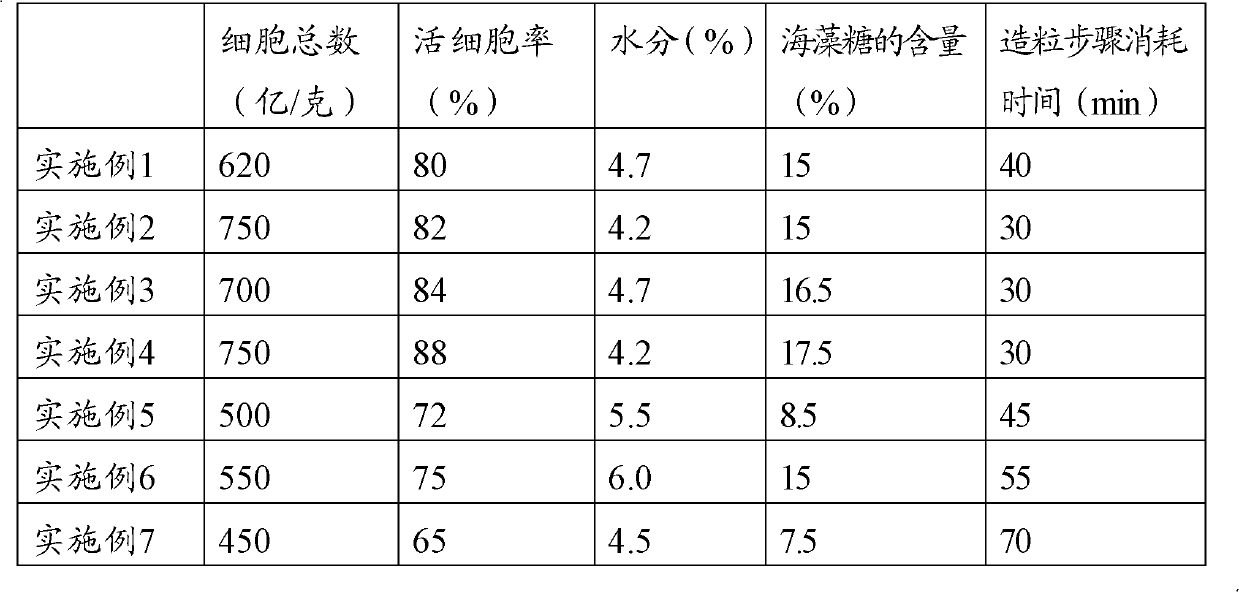

Embodiment 1

[0119] 1) Slant-plane strain cultivation: inoculate the Brady's yeast strain prepared in the preparation example on a solid slope of wort agar with a sugar content of 5% by weight and a pH value of 4, and cultivate it at 26°C for 20 hours to obtain Inclined yeast strains;

[0120] 2) First-level liquid seed F bottle cultivation: Inoculate 1 loop of the slant yeast strain of step 1) into 100 ml of wort F bottle with a sugar content of 5% by weight and a pH value of 4, and cultivate at 26°C After 20 hours, about 100ml of primary liquid seed culture solution was obtained;

[0121] 3) secondary liquid seed Karl Fischer tank culture: step 2) the primary liquid seed culture solution is inoculated into 10 L of wort with a sugar content of 5% by weight, and a pH value of 4 in a Karl Fischer tank. Cultivate at 26°C for 20 hours to obtain about 10L of secondary liquid seed culture solution;

[0122] 4) Fermentation tank seed culture: inoculate the secondary liquid seed culture solutio...

Embodiment 2

[0130] 1) Slant-plane strain cultivation: Inoculate the Brady's yeast strain prepared in the preparation example on a solid slope of wort agar with a sugar content of 20% by weight and a pH value of 5, and cultivate it at 32°C for 48 hours to obtain Inclined yeast strains;

[0131] 2) First-level liquid seed F bottle cultivation: Inoculate 6 loops of the slant yeast strain of step 1) into 250 wort F bottles with a sugar content of 20% by weight and a pH value of 5, and cultivate at 32°C After 48 hours, about 250ml of primary liquid seed culture solution was obtained;

[0132] 3) two-stage liquid seed Karl Fischer jar culture: the first-stage liquid seed culture solution of step 2) is inoculated into the sugarcane molasses with a sugar content of 20% by weight that is equipped with 20L, and the pH value is 5 in a Karl Fischer jar. Cultivate at 32°C for 36 hours to obtain a secondary liquid seed culture solution;

[0133] 4) Seed culture in fermenter: Inoculate the secondary l...

Embodiment 3

[0141] 1) Slant-plane strain cultivation: Inoculate the Brady's yeast strain prepared in the preparation example on a solid slant of wort agar with a sugar content of 10% by weight and a pH value of 6, and cultivate it at 30°C for 36 hours to obtain Inclined yeast strains;

[0142] 2) First-level liquid seed F bottle cultivation: inoculate 4 rings of the slant yeast strain of step 1) into 500 ml of wort F bottle with a sugar content of 10% by weight and a pH value of 6, and cultivate at 30°C After 36 hours, about 500ml of primary liquid seed culture solution was obtained;

[0143] 3) two-stage liquid seed Karst tank culture: the first-stage liquid seed culture solution of step 2) is inoculated into the mixture of wort and sugar beet molasses with a sugar content of 40L, and the pH value is 6. Cultivate at 30°C for 30 hours in a jar to obtain a secondary liquid seed culture solution;

[0144] 4) Fermentation tank seed culture: inoculate the secondary liquid seed culture solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com