Fuel control method for fuel water heater

A technology of gas water heater and control method, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the combustion efficiency of the whole machine, wasting manpower and material costs, and cannot solve the difference of gas sources, etc., and achieves stable and comfortable use, The effect of reducing emissions and using environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

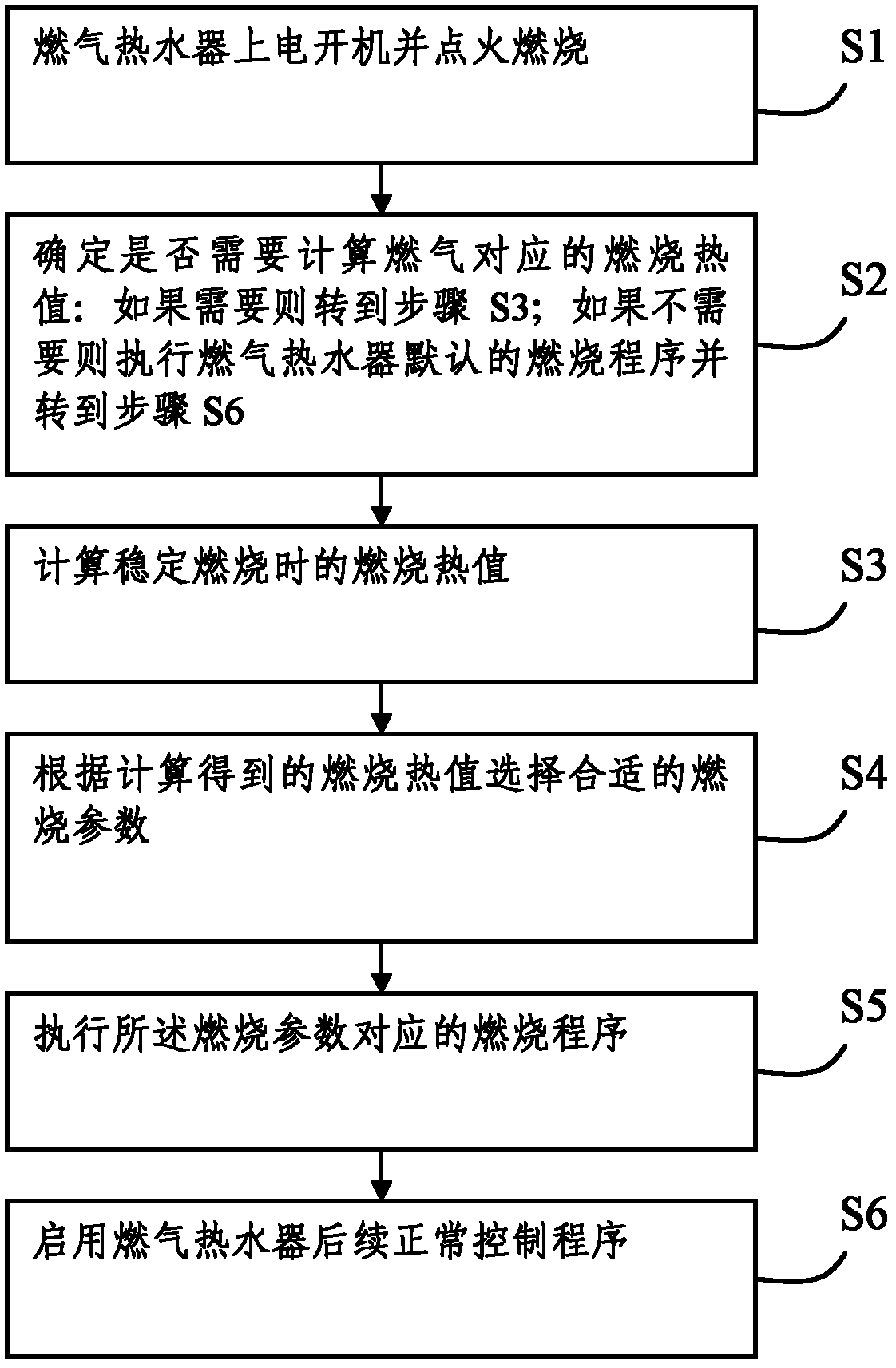

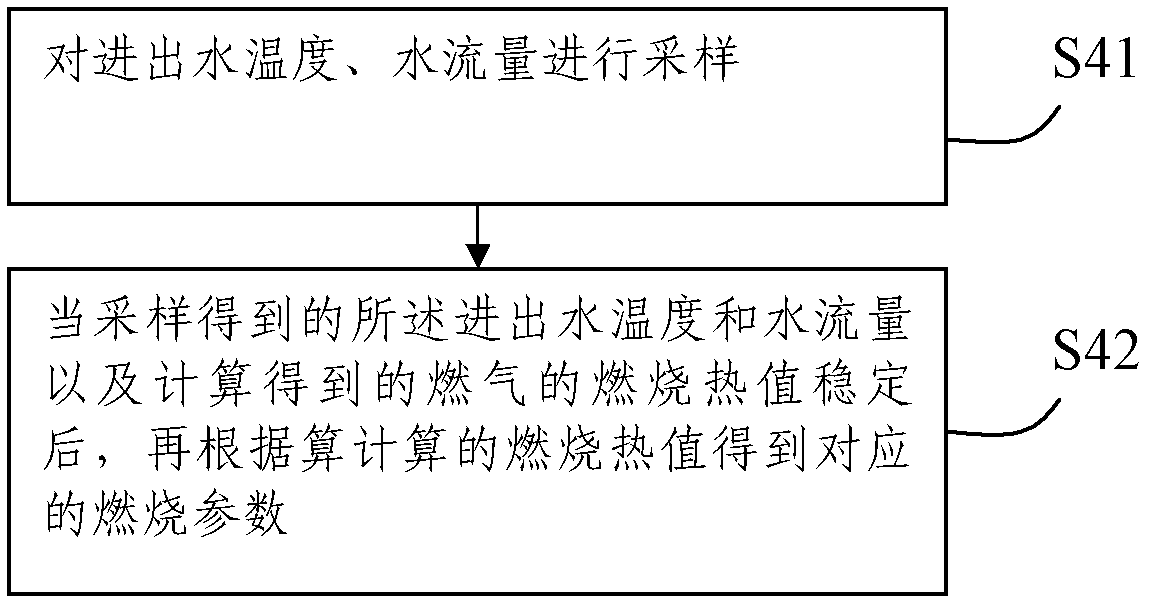

[0031] Such as figure 1 As shown, this embodiment records a gas water heater gas control method, including the following steps:

[0032] S1: The gas water heater is turned on and ignited;

[0033] S2: Determine whether it is necessary to calculate the combustion heat value corresponding to the gas: if necessary, go to step S3; if not, execute the default combustion program of the gas water heater and go to step S6;

[0034] S3: Calculate the combustion calorific value during stable combustion;

[0035] S4: Select appropriate combustion parameters according to the calculated combustion calorific value;

[0036] S5: Execute the combustion program corresponding to the combustion parameters;

[0037] S6: Enable the follow-up normal control program of the gas water heater.

[0038] Through step S2, the user can decide whether to distinguish the gas source, which makes the use more flexible. For example, the user may choose to select the combustion program only when using the g...

Embodiment 2

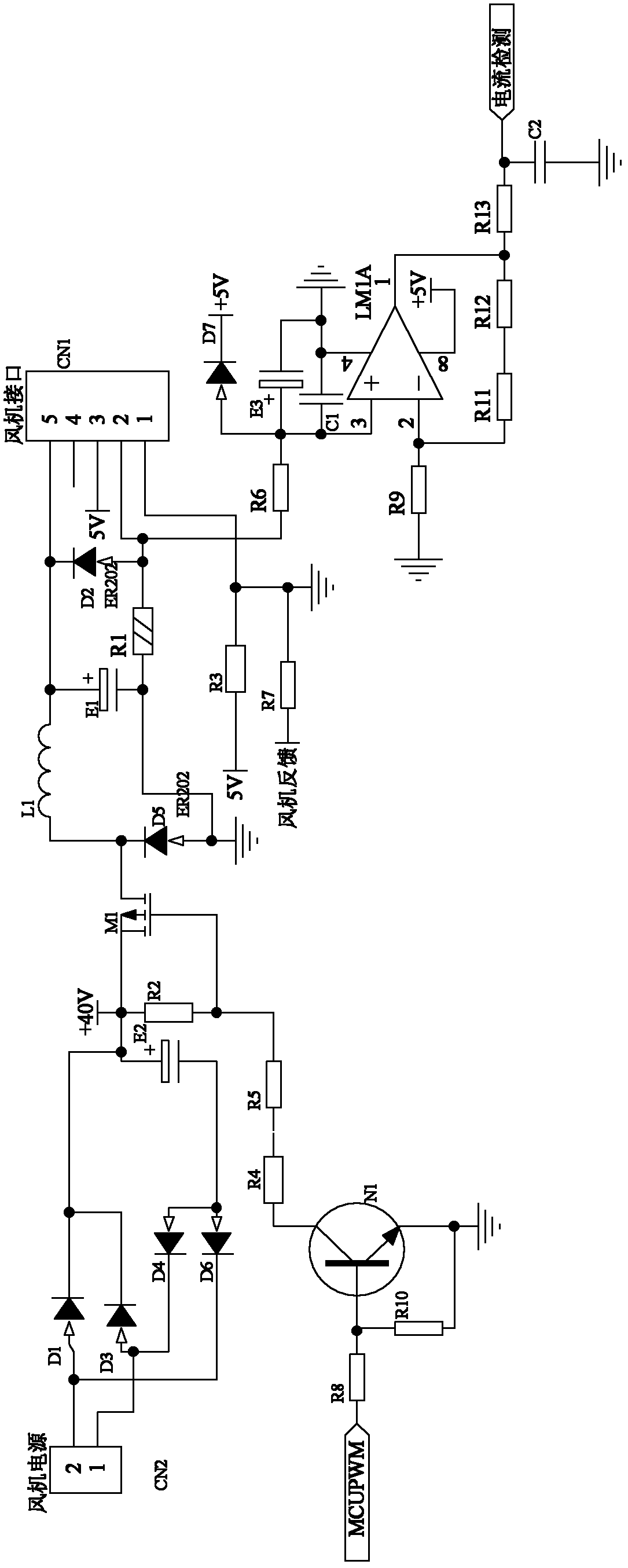

[0045] Such as image 3 Shown is a circuit that detects the current of the fan and controls the fan. The detection and control method is as follows: first, input the pwm (pulse width modulation) signal to the base of the triode N1 through the MCUPWM port, and control the switch of the triode N1; The voltage output by the fan power supply is controlled by the MOS tube M1 chopping to achieve the purpose of controlling the fan speed; the fan current is detected by a resistor R1, and then the signal is amplified by the operational amplifier LM1A and output to the current detection port of the MCU. According to the detected fan current The size of the fan and the size of the wind speed of the fan can determine the size of the external wind pressure, and then control the wind speed of the fan through the MCUPWM port to make up the wind to achieve the purpose of wind pressure resistance.

[0046] In the above control method, due to the influence of the fan itself and the temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com