Snow melting system of photovoltaic power station

A photovoltaic power station, snow melting technology, applied in the directions of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of photovoltaic power station equipment, structural damage, affecting the power generation capacity of photovoltaic power stations, and reducing the power generation capacity of photovoltaic power stations, etc. Reliable and flexible snow melting work, reducing the energy required for heating and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

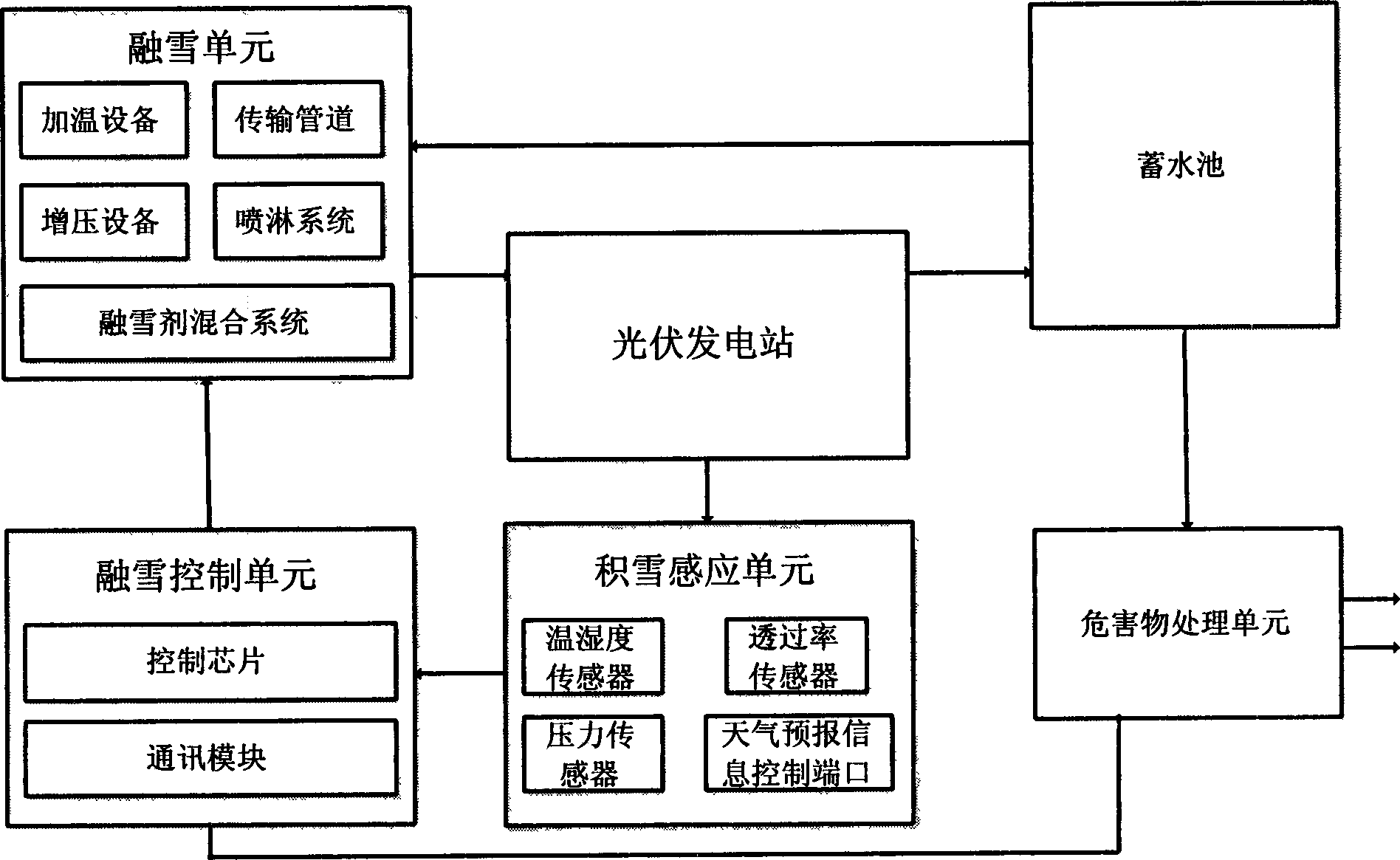

[0023] Embodiments of the present invention are now described with reference to the accompanying drawings, as figure 1 As shown, the present invention provides a photovoltaic power station snow melting system, including a snow sensing unit, a snow melting control unit, a snow melting unit, a water storage tank and a hazard treatment unit, wherein:

[0024] The snow sensing unit is connected to the photovoltaic power station, and is used to continuously sense snow and weather information on the photovoltaic power station, and transmit the sensed snow thickness, weather conditions and other information to the snow melting control unit;

[0025] The snow melting control unit is connected to the snow sensing unit, the snow melting unit and the hazard processing unit, and is used to receive the sensing information of the snow sensing unit, and start the corresponding snow melting mode according to the snow thickness, weather conditions and other information; during the snow melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com