Half slot finish machining process of sewing machine press foot

A sewing machine presser foot and semicircular groove technology, which is applied to the sewing machine presser foot field, can solve problems such as short delivery time, and achieve the effects of reducing man-hours, good size consistency, and simplifying the shape of the blank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows: embodiment

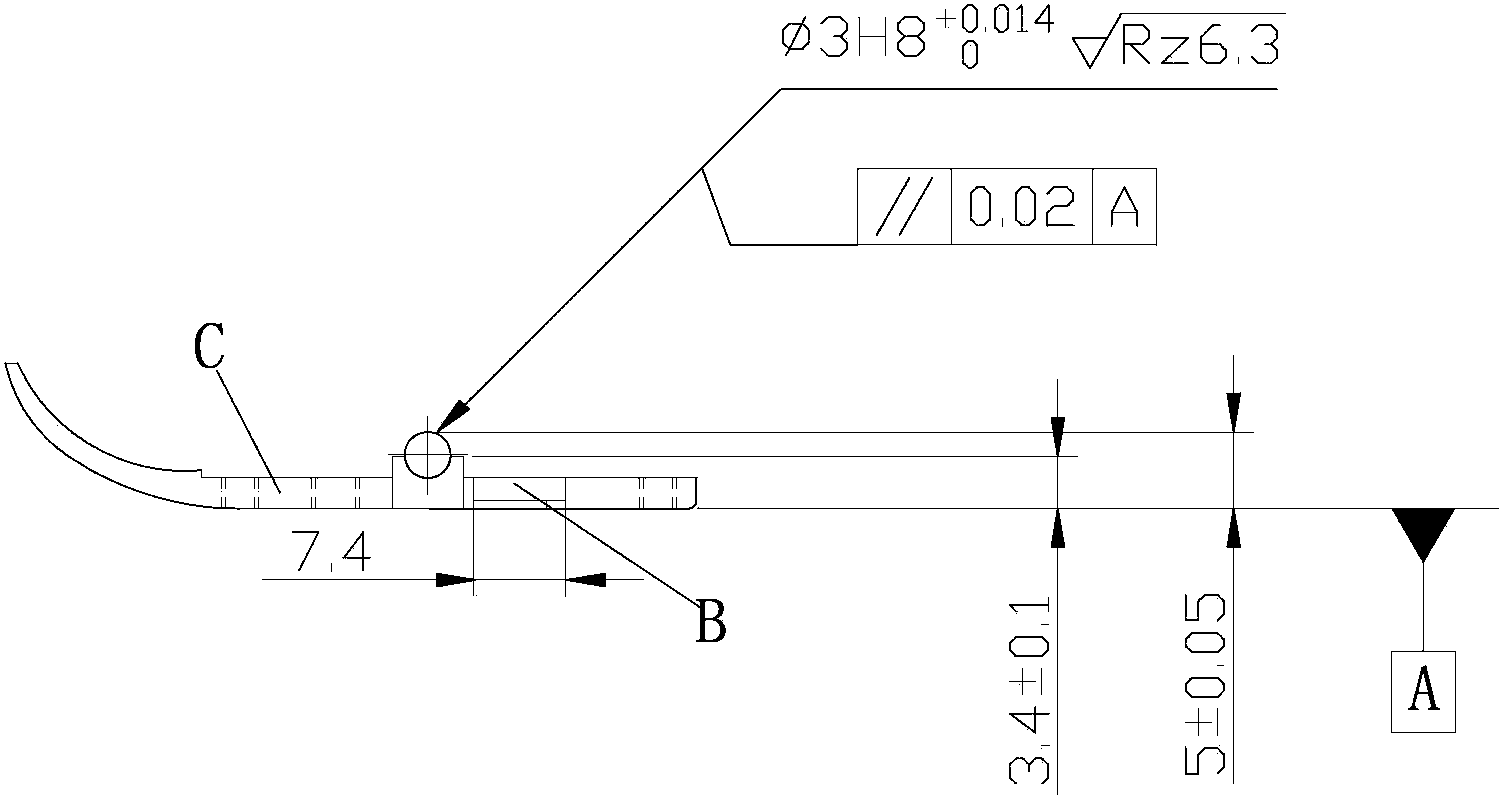

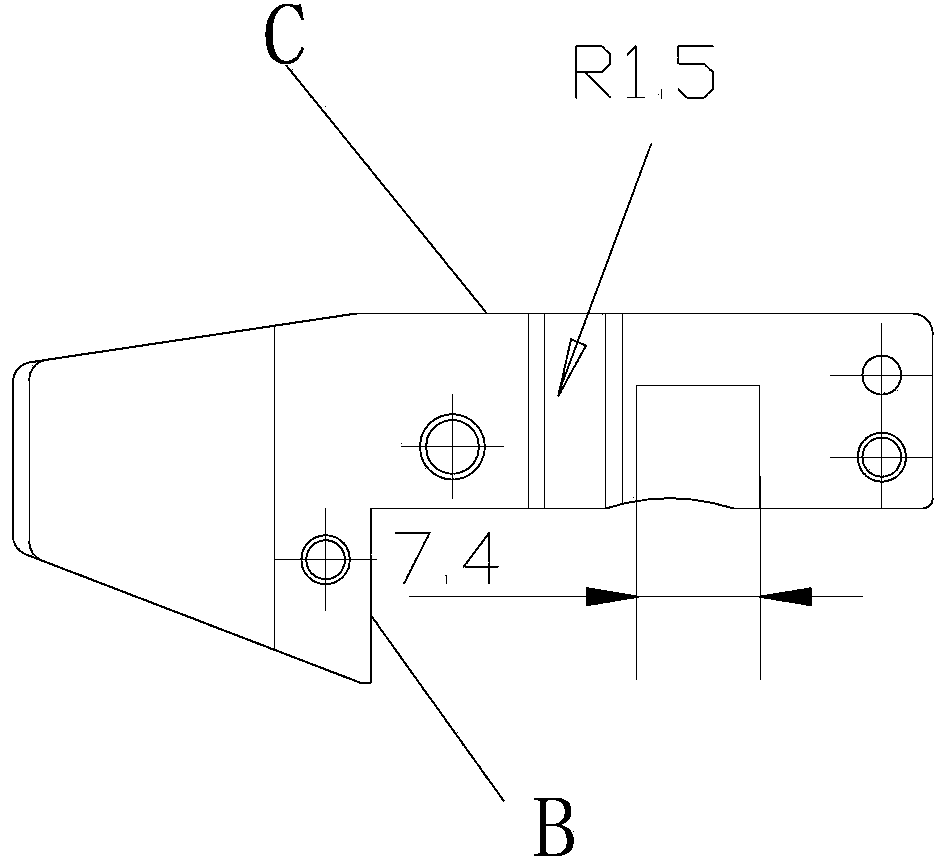

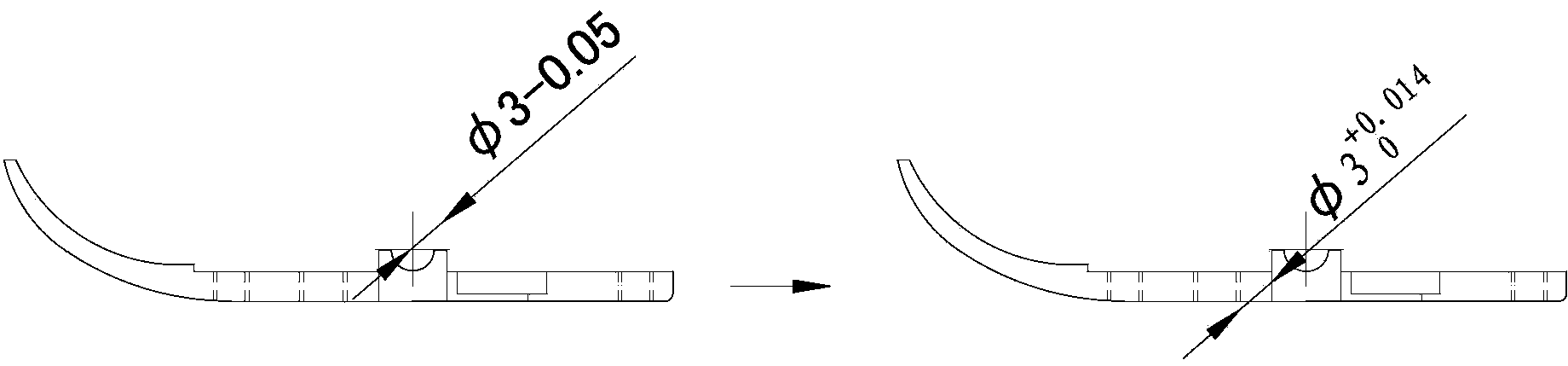

[0028] See details image 3 , the present invention provides a semi-circular groove finishing process of the sewing machine presser foot, the specific process is as follows,

[0029] The first sequence of blank inspection (outsourcing): according to the requirements of the blank drawing, check whether the blank produced by precision casting is qualified according to the ratio of 10%;

[0030] The second step is to remove the excess nozzle left by the side wall of the blank;

[0031] The third step is to level the bottom surface of the blank: artificial hand hammer to adjust the flatness of the bottom surface of the blank to ensure the machining allowance of the next process;

[0032] The fourth step is to grind the bottom surface of the blank as the processing reference surface A: use a general-pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com