Skin-core type terylene antibacterial fiber and preparation method thereof

An antibacterial fiber, skin-core type technology, applied in the field of skin-core polyester antibacterial fiber and its preparation, can solve the problems of fiber mechanical properties, waste, expensive nano-silver, etc., achieve broad-spectrum antibacterial effect, improve antibacterial effect, reduce The effect of usage

Inactive Publication Date: 2013-11-06

JIANGSU ZJA NEW MATERIAL

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the natural antibacterial performance is good, the dosage is large, and spinning is more difficult, which seriously affects the mechanical properties of the fiber.

[0004] Nano-silver has a good antibacterial effect, adding a small amount can have a good antibacterial effect, and will not affect the spinning process and fiber performance indicators, but nano-silver is still very expensive, using the blended spinning method, nano-silver Dispersed in the entire volume of the fiber, the nano-silver inside the fiber does not contribute to the antibacterial effect, resulting in waste

[0005] In addition, the antibacterial effect of antibacterial fiber is always positively correlated with the amount of antibacterial agent added, but due to cost factors, the amount of nano silver added cannot be increased arbitrarily.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

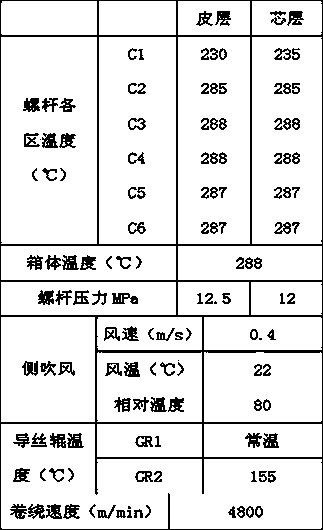

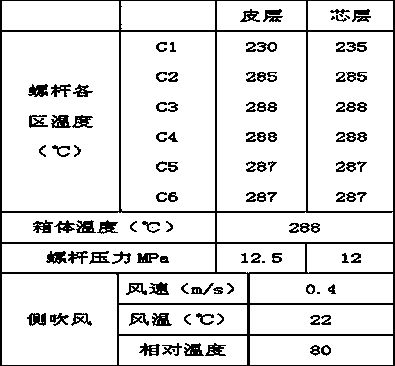

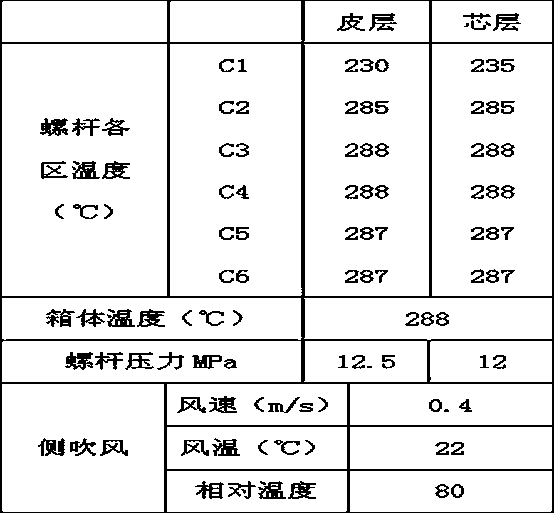

[0019] Polyamide 6 slices are used for the core layer, 8 parts of polyester antibacterial masterbatch are used for the skin layer, 92 parts of polyamide 6 slices are mixed, the feeding ratio of the skin layer and the core layer is 25-75%, and the composite spinning system is used for spinning. Core composite spinneret. The specific process is as follows:

[0020]

[0021] The physical index of the obtained antibacterial fiber

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a skin-core type terylene antibacterial fiber and a preparation method thereof. The skin-core type terylene antibacterial fiber possesses a skin-core structure; a skin layer comprises, by weight, 4 to 15% of terylene antibacterial master batch and 85 to 96% of polyamide-6 granula; a core layer is made of polyamide-6 granula; and the weight percentage of the skin layer is 20 to 40%, and the weight percentage of the core layer is 60 to 80%. The skin-core type terylene antibacterial fiber is capable of increasing the content of nano-silver on partial surface of the fiber, and achieving long-lasting, high-efficient and broad-spectrum antibacterial effects; after 100 times of washing, the antibacterial ratio of the skin-core type terylene antibacterial fiber is 99% or more; the application amount of terylene antibacterial master batch is reduced greatly, cost is saved, and antibacterial effects are improved. The skin-core type terylene antibacterial fiber is suitable of the field of functional chemical fibre.

Description

Technical field: [0001] The invention relates to the field of functional chemical fibers, in particular to a sheath-core polyester antibacterial fiber and a preparation method thereof. Background technique [0002] The processing of antibacterial chemical fibers and fabrics mainly adopts the following two methods: finishing and fiber modification. The post-finishing method is mainly based on organic antibacterial agents, such as quaternary ammonium salt antibacterial agents. Because this method is to attach the antibacterial active ingredient to the surface of fibers and fabrics, the antibacterial products made are not resistant to washing and have poor durability. Therefore, this method is gradually replaced by fiber modification. The fiber modification method is mainly to add antibacterial agents to fiber-forming polymers to obtain permanent antibacterial fibers. Among them, blending modification is the main one. [0003] The antibacterial agents commonly used in the b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F8/12D01F8/14D01F6/92D01F1/10D01D5/34D01D5/08

Inventor 周焕民

Owner JIANGSU ZJA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com