Temporary support and permanent support parallel operation excavating technology and equipment for tracked hydraulic combined support

A temporary support and hydraulic support technology, applied in mining equipment, mine roof support, earthwork drilling and other directions, can solve the problems of unfavorable roof support, unreachable support area, easily damaged roof, etc., and achieve the working environment of workers. The effect of safety and reliability, improving the tunneling speed and improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

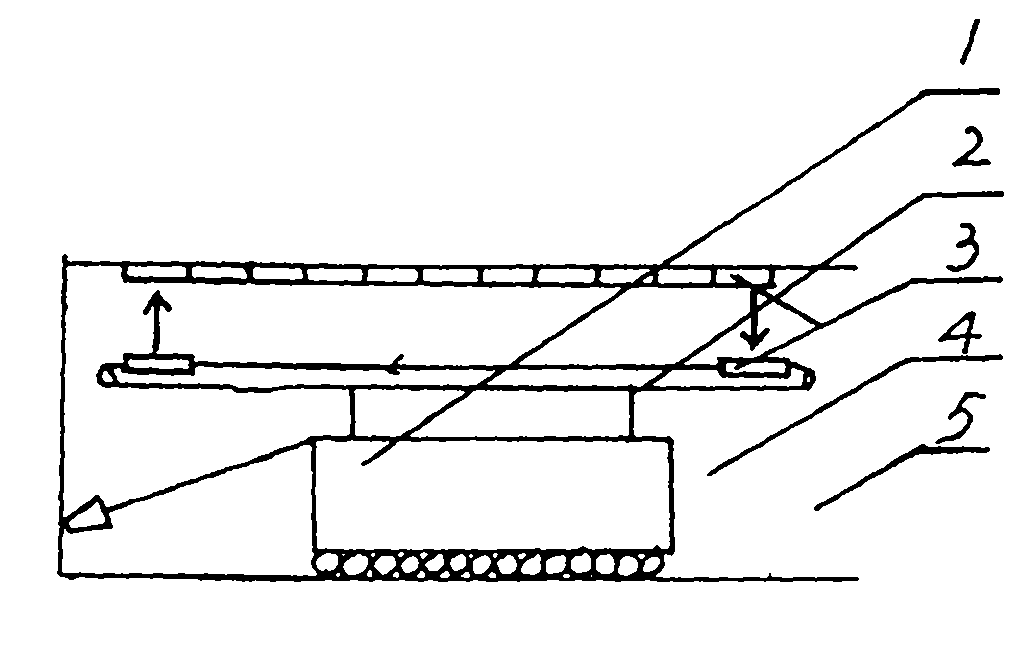

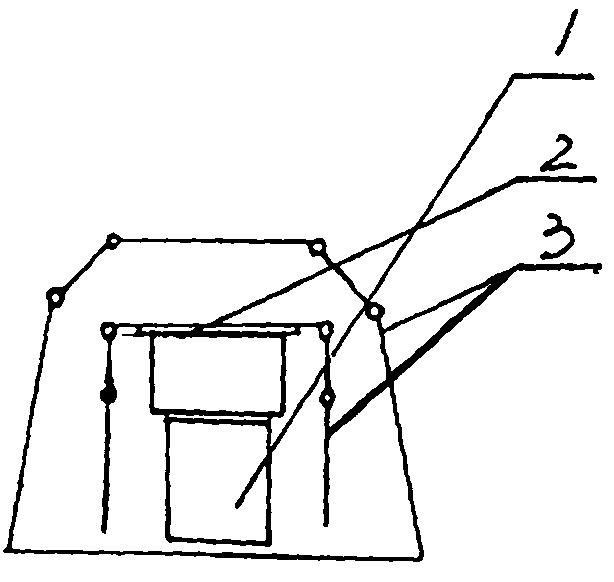

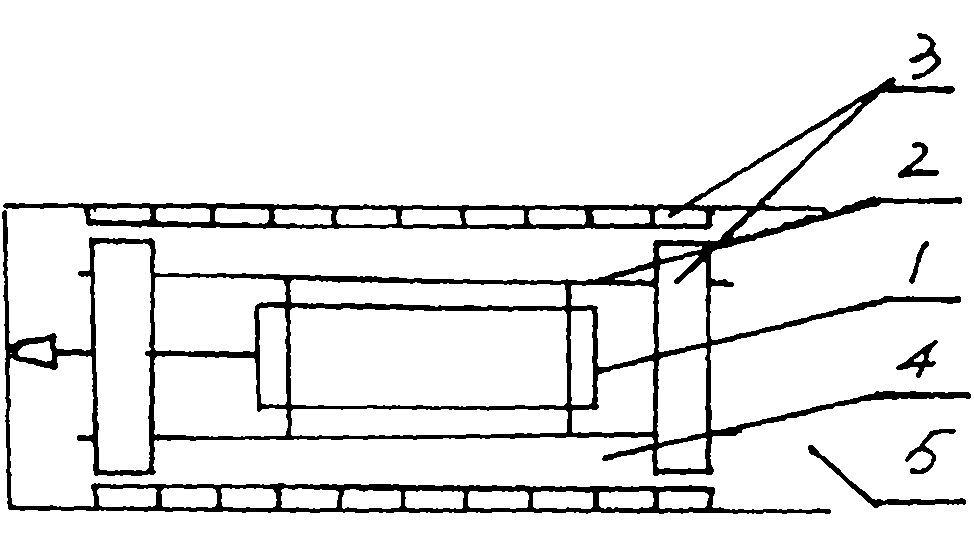

[0045] A "crawler-type" hydraulic combination support temporary support and permanent support parallel operation excavation technology divides the excavation working face into a temporary support area (4) and a permanent support area (5); the roadheader operation area is the temporary support area The protection area (4), followed by the permanent support area (5); the temporary support area (4) adopts the "crawler type" hydraulic combined support front support and back return process for temporary support; the permanent support and roadheader cutting Work at the same time. The "crawler type" hydraulic combined support consists of several hydraulic supports (3).

[0046] The described front support and back return process is that several hydraulic supports (3) are arranged side by side along the axis direction of the excavation roadway to support the temporary support area (4). The temporary support at the end of the temporary support area is withdrawn, transported to the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com