Potassium chloride triple-effect evaporation system capable of improving heat energy utilization rate

A technology of three-effect evaporation and three-effect evaporator, applied in multi-effect evaporation, alkali metal chloride, chemical industry, etc., can solve the problems of failure to achieve energy saving and emission reduction, heat energy not being utilized, evaporator cannot be produced, etc., to achieve Avoid corrosion of equipment, low degree of transformation, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

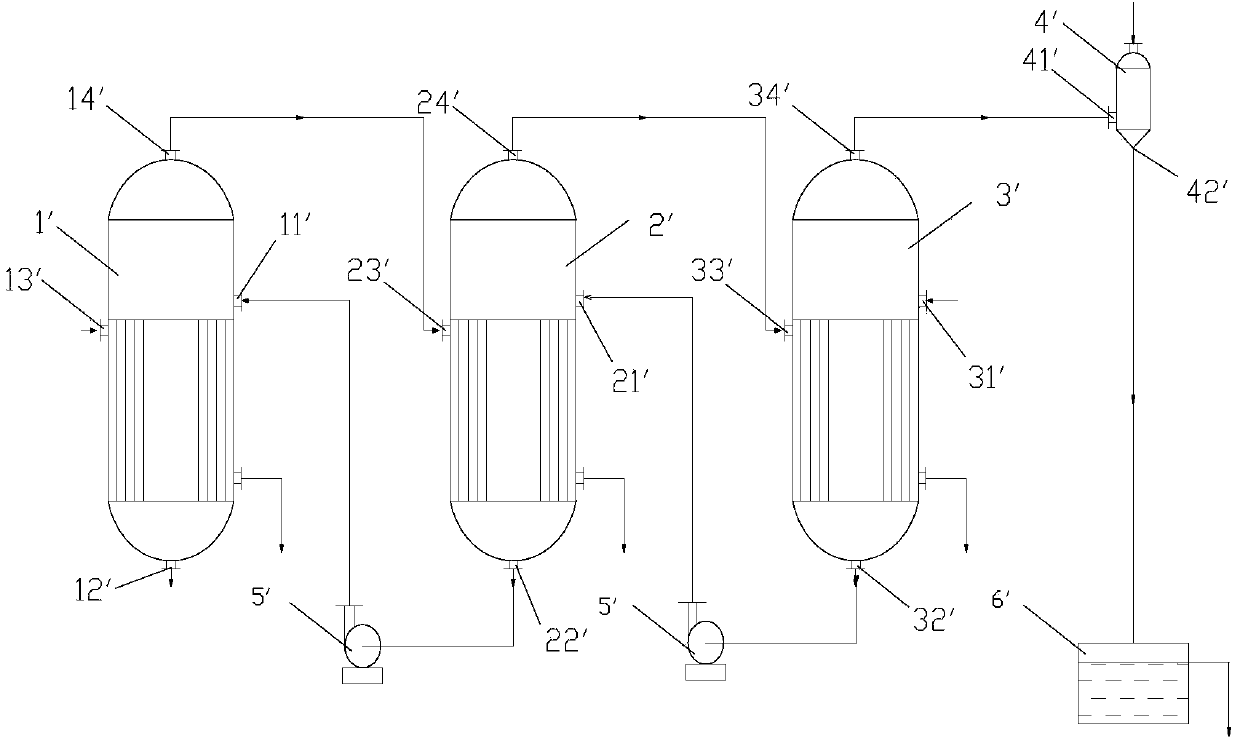

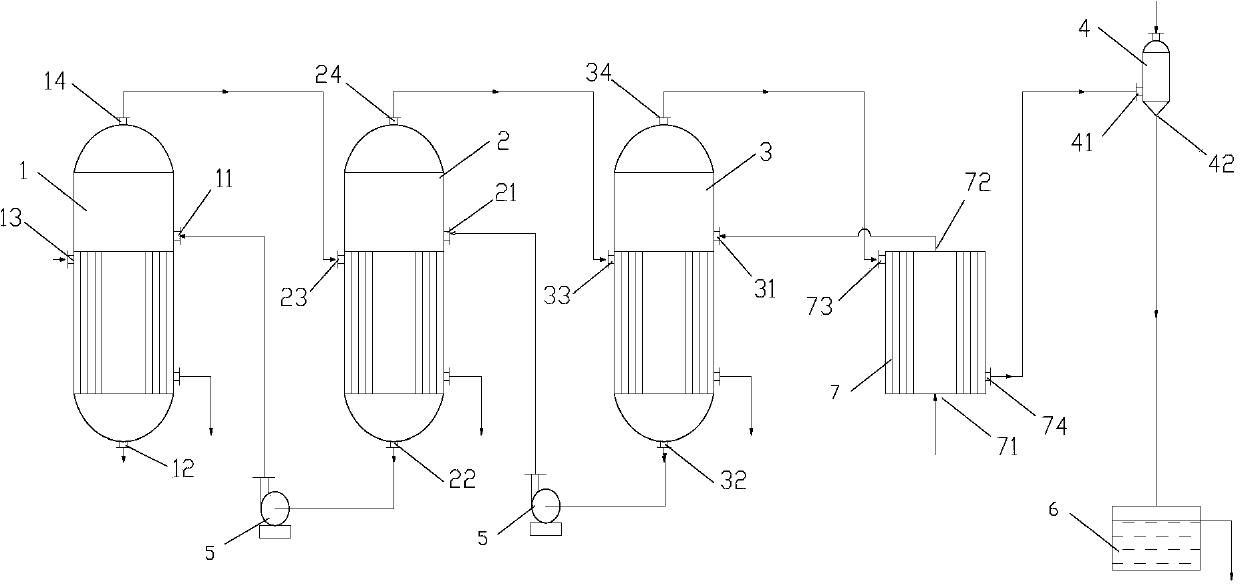

[0017] like figure 2 As shown, a potassium chloride three-effect evaporation system for improving heat energy utilization rate includes a single-effect evaporator for evaporating feed liquid and having a feed inlet, a feed outlet, a steam inlet, a steam outlet, and a condensed water outlet. 1. The two-effect evaporator 2 and the three-effect evaporator 3 are sequentially connected between the discharge port 32 of the three-effect evaporator and the feed port 21 of the two-effect evaporator, the discharge port 22 of the two-effect evaporator and the Two transfer pumps 5 between the feed ports 11 of the first-effect evaporator, the steam outlet 14 of the first-effect evaporator is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com