Inner sleeve plate structure of packed fractionating tower

A technology of fractionation tower and casing, which is applied in the field of casing structure in packed fractionation tower, can solve problems such as coking, fouling, blockage, etc., and achieve the effects of preventing coking, improving gas-liquid distribution, and improving mass transfer efficiency

Active Publication Date: 2013-11-13

CHINA PETROCHEMICAL CORP +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to improve the gas-liquid load distribution in the packing bed of the fractionation tower, improve the process performance of the corresponding packing bed, and effectively avoid the phenomenon of coking, scaling, and clogging of materials in the packing bed, the invention provides a packing fractionation Tower inner casing structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

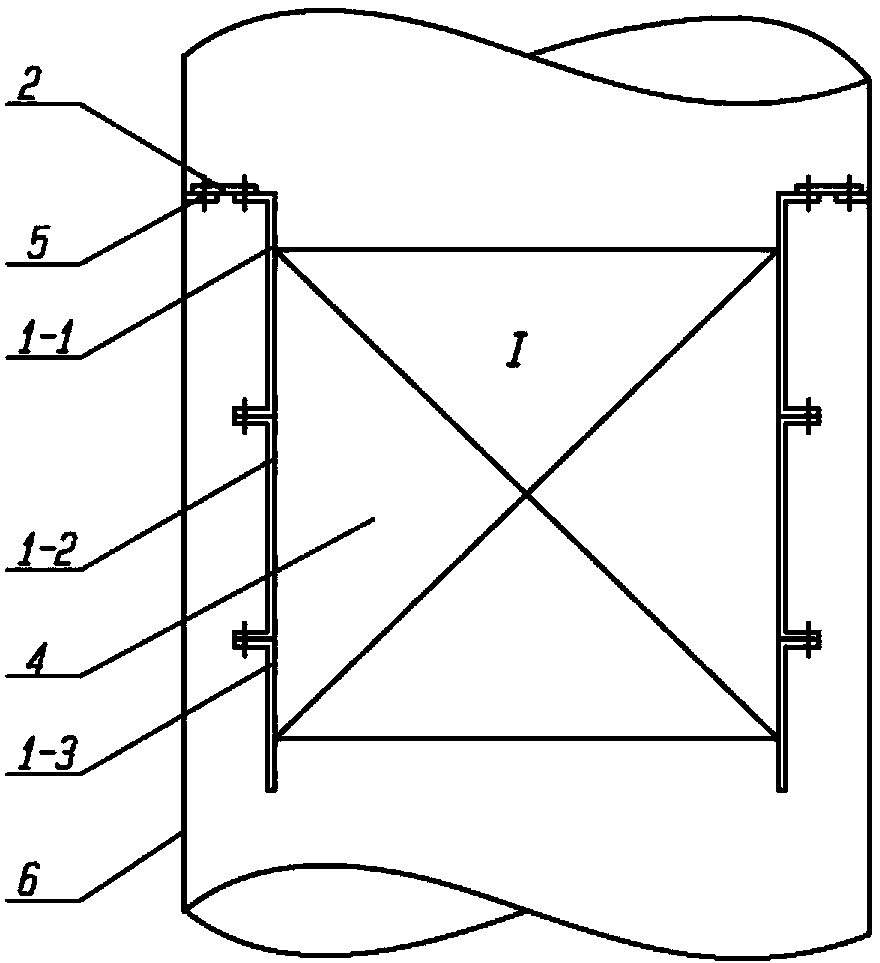

[0039] The number of the inner sleeve plate structure is one.

Embodiment 2

[0041] There are two inner casing structures, and the embodiment provides a relative positional relationship between the two inner casings, and the two inner casings are perpendicular to each other.

Embodiment 3

[0043] The number of inner sleeve board structures is three, and the inner sleeve boards are perpendicular or parallel to each other.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

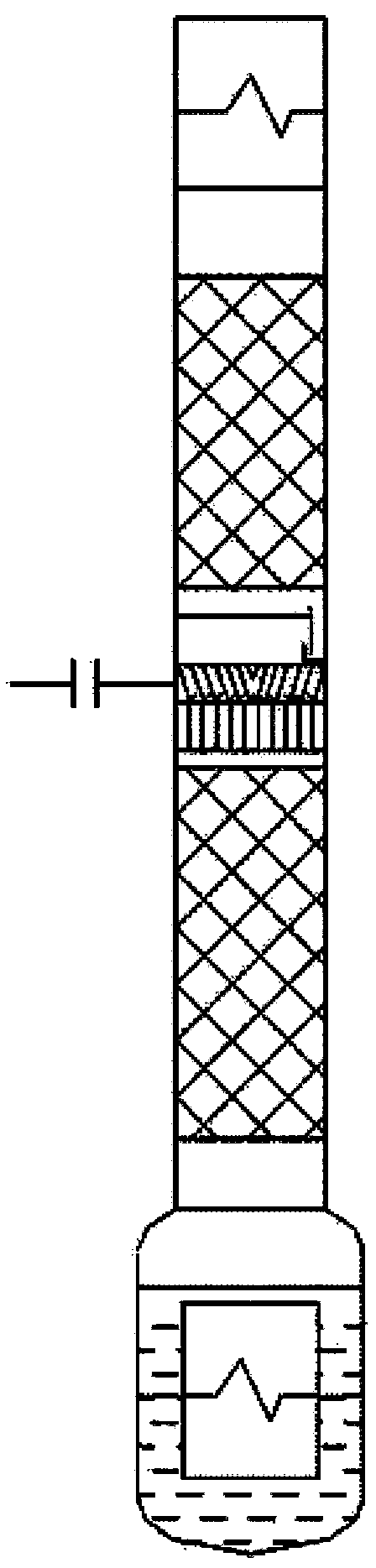

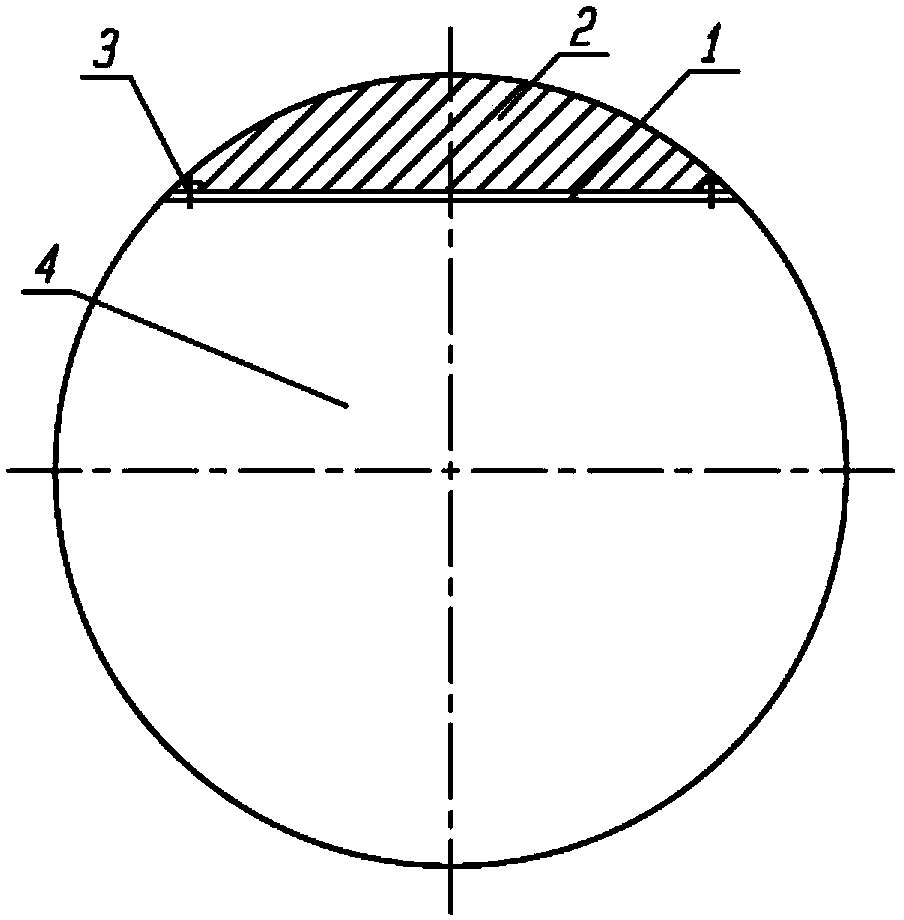

The invention relates to an inner sleeve plate structure of a packed fractionating tower. The inner sleeve plate structure comprises at least one inner sleeve plate; the inner sleeve plate structure is along a tower height direction; namely, at least one inner sleeve plate is fixed in the tower along the wall of the packed fractionating tower. The inner sleeve plate structure is used for changing an overflowing area of a packed bed layer and improving gas-liquid distribution condition in the packed bed layer. The inner sleeve plate structure increases mass transfer efficiency, improves process performance of the fractionating tower, increases spraying density above the packed materials, prevents high temperature poor quality oil from coking in the packed bed layer, and reduces equipment investment.

Description

technical field [0001] The invention relates to an internal part of a fractionation tower, in particular to an inner sleeve plate structure of a packing fractionation tower. Background technique [0002] As an important mass transfer separation equipment in petroleum, petrochemical, pharmaceutical and other fields, packed fractionation column is widely used. Packed tower internals mainly include packed bed, feed distributor (distribution pipe), oil collection tank, gas distributor, liquid phase distributor and other structures. [0003] In engineering practice, the gas-liquid load of each packed bed in the packed fractionation column often has a large difference, and the selection of the tower diameter must meet the requirements of the maximum loaded packed bed, which will lead to some packed beds or gas-phase loads Too low, or the liquid phase load is too low, or both gas and liquid loads are low, resulting in low mass transfer and heat transfer efficiency in the packed be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D3/32

Inventor 王亚彪袁毅夫王秋萍

Owner CHINA PETROCHEMICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com