The production method of methyl nitrite

A technology of methyl nitrite and a production method, which is applied in the production field of methyl nitrite, can solve the problems of high nitrogen oxide supply cost, equipment corrosion, etc., so as to improve gas-liquid distribution, ensure conversion rate, and improve reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

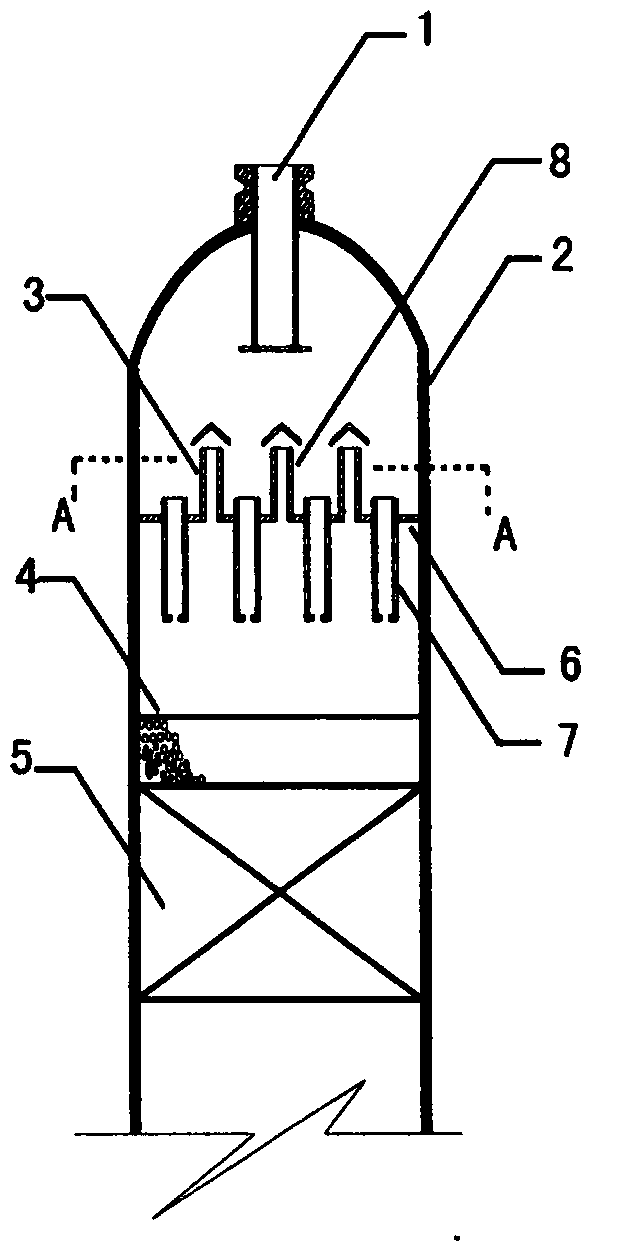

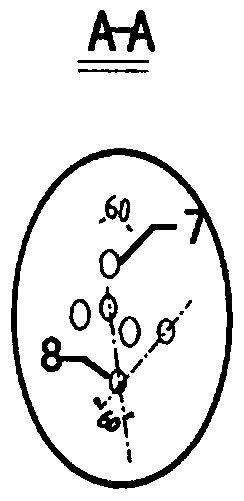

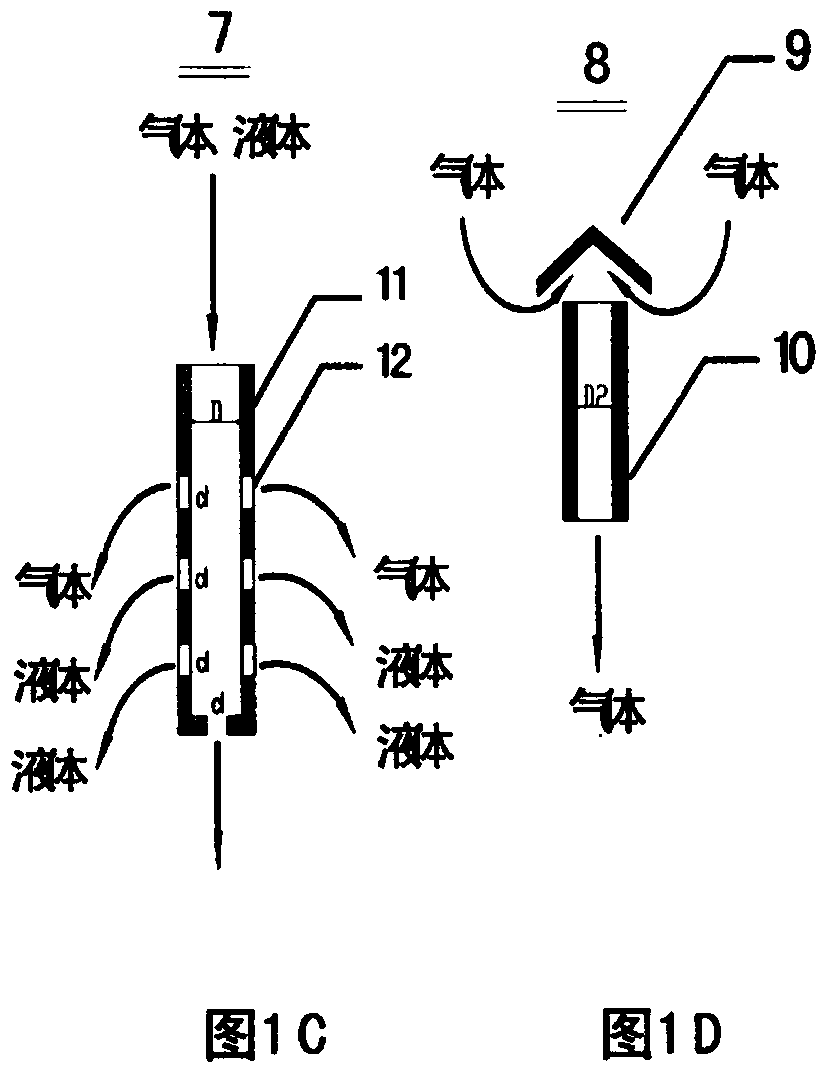

[0038] A trickle bed reactor as shown in Fig. 1 is used. Wherein, the upper end of the gas-liquid distributor short pipe 11 extends 50 mm above the distribution plate 6, and the lower end extends 500 mm below the distribution plate 6, and the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.015:1.0 , the ratio of the area S1 of all small holes 12 to the area S2 of the cross-section in the liquid passage pipe 7 is 1.01: 1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 15%, and the liquid passage pipe 7 is on the distribution plate 6 on the opening rate of 20%.

[0039] The catalyst in the reactor uses active carbon as a carrier, and the catalyst is composed of: 12% nickel metal, 3% iron as a metal additive, 3% titanium as a metal additive, and the balance as a carrier. The mixed liquid (nitric acid: 1%wt, methanol: 99%wt) and the mixed gas (CO: 25%v / v, NO: 10%v / v, CO 2 : 15% v / v, MN: 5% v / v, ...

Embodiment 2

[0041] A trickle bed reactor as shown in Fig. 1 is used. Wherein, the upper end of the gas-liquid distributor short pipe 11 extends 25 mm above the distribution plate 6, and the lower end extends 800 mm below the distribution plate 6, and the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.011:1.0 , the ratio of the area S1 of all small holes 12 to the area S2 of the cross-section in the liquid passage pipe 7 is 0.95:1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 10%, and the liquid passage pipe 7 is on the distribution plate 6 on the opening rate of 15%.

[0042] The catalyst in the trickle bed reactor uses silicon oxide as a carrier, and the catalyst composition is: 5% metallic nickel, 10% titanium as a metal additive, and the rest as carrier. The mixed liquid (nitric acid: 15%wt, water: 30%wt, methanol: 55%wt) and the mixed gas containing NO (CO: 30%v / v, NO: 15%v / v, CO 2 : 15% v / v, M...

Embodiment 3

[0044] A trickle bed reactor as shown in Fig. 1 is used. Wherein, the upper end of the gas-liquid distributor short pipe 11 extends 80 mm above the distribution plate 6, and the lower end extends 650 mm below the distribution plate 6, and the ratio of the diameter d of the small hole 12 to the inner diameter D of the liquid channel pipe 7 is 0.15:1.0 , the ratio of the area S1 of all small holes 12 to the area S2 of the cross-section in the liquid passage pipe 7 is 1.1: 1.0; the opening ratio of the gas passage pipe 8 on the distribution plate 6 is 20%, and the liquid passage pipe 7 is on the distribution plate 6 on the opening rate of 30%.

[0045] The catalyst in the trickle bed reactor is supported by activated carbon, and the catalyst is composed of: 25% nickel metal, 1% iron as a metal additive, 0.5% titanium as a metal additive, and the balance as a carrier. The mixed liquid (nitric acid: 5%wt, water: 8%wt, methanol: 87%wt) and the mixed gas containing NO (CO: 20%v / v, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com