Trickle bed equipment for preparing m-Metaxylenediamine

A m-xylylenediamine, trickle bed technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problem of unfavorable gas-liquid smooth flow state, catalyst deactivation bed pressure drop, and large bed pressure drop and other problems, to achieve the effects of improving gas-liquid distribution, reducing the formation of polymerization by-products, and reducing hydrogenation temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

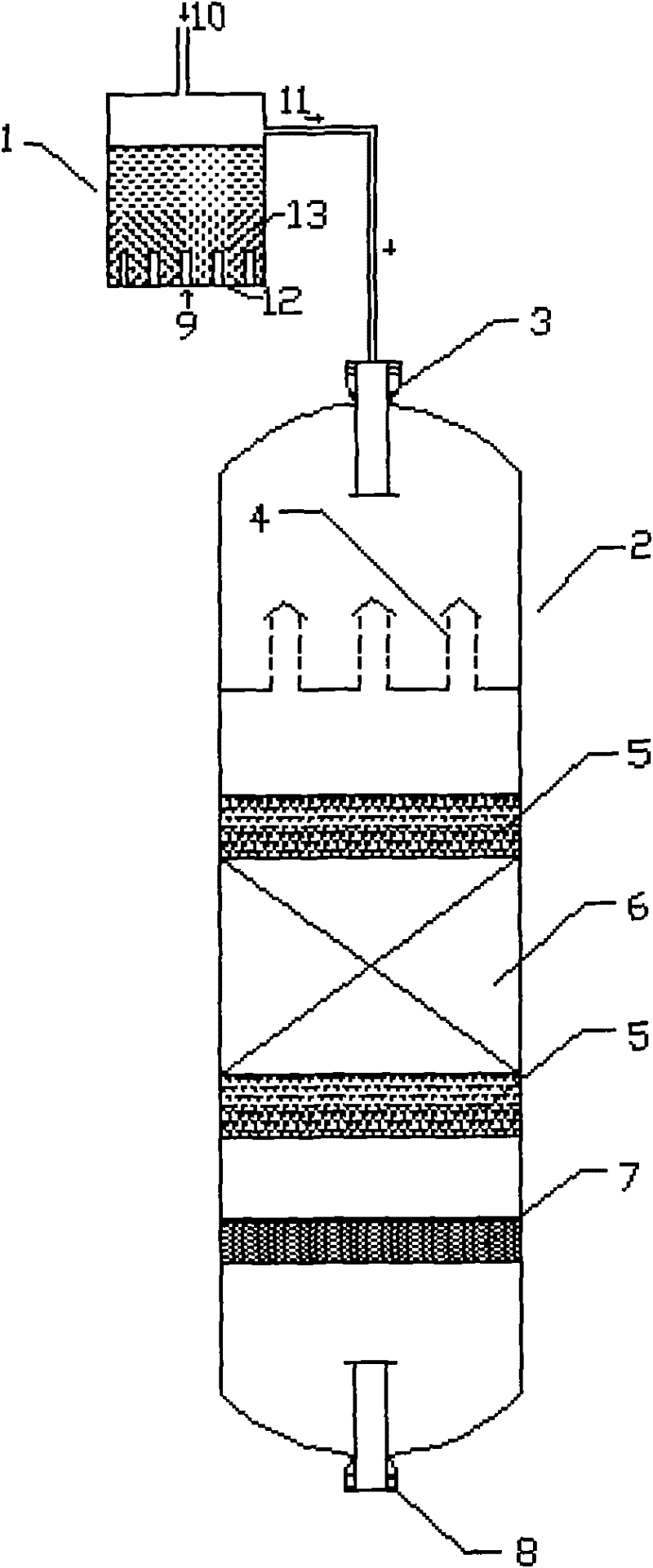

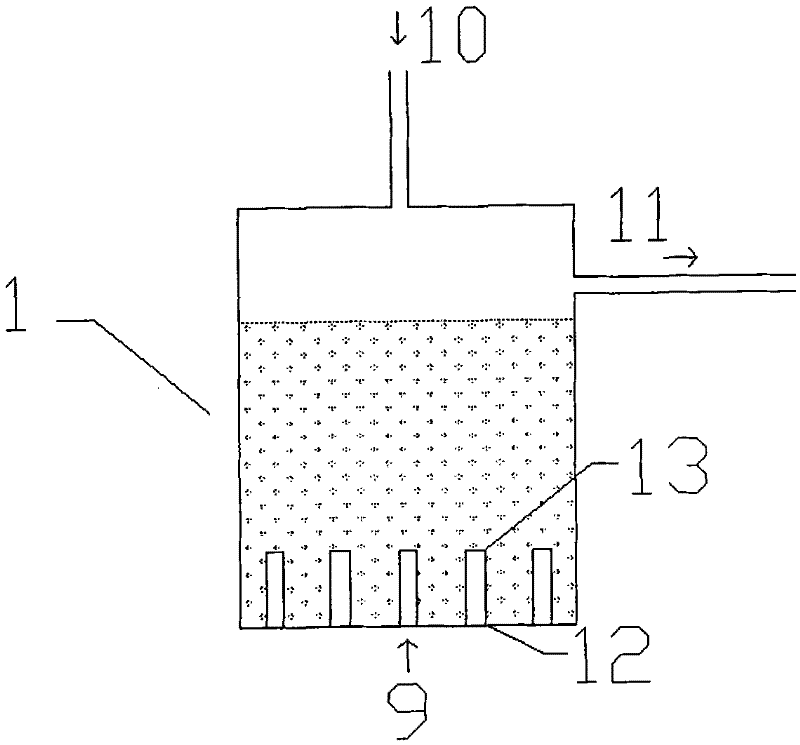

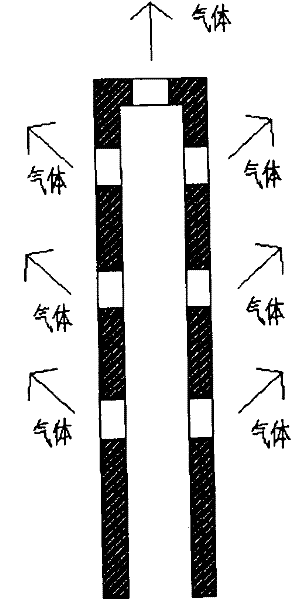

[0031] A trickle bed equipment for preparing m-xylylenediamine, comprising a gas-liquid mixer 1, a reactor shell 2, a feed inlet 3, a gas-liquid distributor 4, a ceramic ball bed 5, a catalyst bed 6, and an outlet Distributor 7 and outlet 8;

[0032] Adopt the following gas-liquid mixer: the opening ratio on the bottom plate 12 is 20%, the diameter of the short pipe 13 and the diameter of the mixer floor 12 are 1:35, the height of the short pipe 13 and the mixer outlet 11 bottom plate 12 The height ratio of the short pipe 13 is 1:30, the ratio of the diameter of the circular air outlet on the short pipe 13 to the height of the short pipe is 1:35, and the opening ratio of the air outlet of the short pipe 13 is 15%; the inner diameter of the trickle bed is 150mm . Gas enters from the gas inlet 9 below the mixer, and liquid enters from the liquid inlet 10 above.

[0033] Use this gas-liquid mixer for trickle bed hydrogenation of m-xylylenediamine:

[0034] Adopt the nickel ser...

Embodiment 2

[0040] Adopt following gas-liquid mixer: the opening rate on the bottom plate 12 is 10%, the diameter of the short pipe 13 and the diameter of the mixer floor 12 are 1: 20, the height of the short pipe 13 and the height of the mixer outlet 11 bottom plate The height ratio is 1: 10, the ratio of the diameter of the circular air outlet on the short pipe 13 to the height of the short pipe is 1: 20, and the opening ratio of the air outlet of the short pipe 13 is 10%; the trickle bed inner diameter is 100mm.

[0041] Use this gas-liquid mixer for trickle bed hydrogenation of m-xylylenediamine:

[0042] Adopt the supported nickel series catalyst, supply from the top of the trickle bed reaction tube with the mixed solution of isophthalonitrile, m-xylene and ammonia, supply hydrogen (over 200 times) from the top of the reaction tube at the same time, at pressure 6MPa, temperature Continuous hydrogenation reaction was carried out at 60°C. Gained reactor outlet liquid is analyzed with ...

Embodiment 3

[0044] Adopt following gas-liquid mixer: the opening rate on the bottom plate 12 is 30%, the diameter of the short pipe 13 and the diameter of the mixer bottom plate 12 are 1:50, the height of the short pipe 13 and the distance between the mixer outlet 11 and the floor The height ratio is 1:50, the ratio of the diameter of the circular air outlet on the short pipe 13 to the height of the short pipe is 1:50, and the opening ratio of the air outlet of the short pipe 13 is 20%; the trickle bed internal diameter is 200mm.

[0045] Use this gas-liquid mixer for trickle bed hydrogenation of m-xylylenediamine:

[0046]Adopt the supported nickel series catalyst, supply from the top of the trickle bed reaction tube with the mixed solution of isophthalonitrile, m-xylene and ammonia, supply hydrogen (over 200 times) from the top of the reaction tube at the same time, at pressure 6MPa, temperature Continuous hydrogenation reaction was carried out at 60°C. Gained reactor outlet liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com