Plant material adsorbent for reducing cadmium content of tobacco extracting liquid and application of plant material adsorbent

A plant material and adsorbent technology, applied in tobacco, application, treatment of tobacco and other directions, can solve the problems of high cost, complex process, incorporation, etc., and achieve the effects of low cost, wide distribution and rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

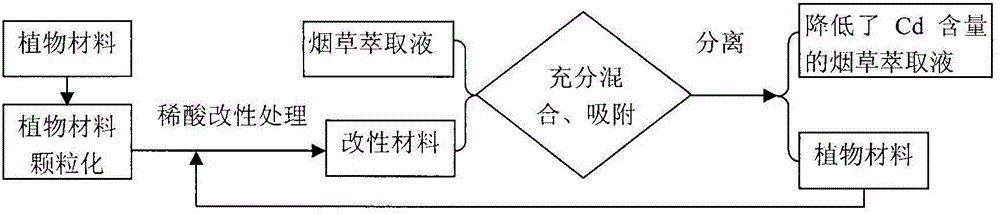

Method used

Image

Examples

experiment example 1

[0021] Preparation of tobacco extract: Select 2 samples of tobacco powder in the middle part of flue-cured tobacco leaves, code-named A and B, weigh 1.0 g of tobacco powder respectively, put them into a 50 ml centrifuge tube, add 20 ml of water, place on a shaker at 200 rpm Shake for 2 hours, filter with a nylon filter membrane (above 150 mesh) with a pore size of less than 100 microns, and the filtrate is the tobacco extract.

[0022] Preparation of adsorbent: Grind Pokeweed root system, take 10 g of the part with a particle size between 0.1 mm and 0.3 mm (that is, the part that passes through a 40-mesh nylon sieve but cannot pass through a 150-mesh nylon sieve), add Shake 250 ml of 0.1 mol / L hydrochloric acid for 2 hours, filter through a 150-mesh nylon sieve, and then wash the modified Pokeweed root particles with deionized water for 3 times. Drying is ready-to-use adsorbent.

[0023] Take 10 ml of tobacco extracts from tobacco powder samples A and B respectively, add 0.5 ...

experiment example 2

[0025] Preparation of tobacco extract: select 3 samples of tobacco powder in the middle of the flue-cured tobacco leaves, code-named C, D and E, weigh 0.2 g of tobacco powder respectively, put them into a 50 ml centrifuge tube, add 20 ml of water, and place on a shaker for 200 Vibrate at rpm for 2 hours, filter with a nylon filter membrane (above 150 mesh) with a pore size of less than 0.1 mm, and the filtrate is the tobacco extract.

[0026] Preparation of adsorbent: Grind Pokeweed root system, take 10 g of the part with a particle size between 0.1 mm and 0.3 mm (that is, the part that passes through a 40-mesh nylon sieve but cannot pass through a 150-mesh nylon sieve), add Shake 500 ml of 0.05 mol / L nitric acid for 2 hours, filter with a 150-mesh nylon sieve, and then wash the modified Pokeweed root particles with deionized water for 3 times. Drying is ready-to-use adsorbent.

[0027] Take 15 ml of tobacco extracts from tobacco dust samples C, D and E, add 0.2 g of adsorben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com