Multilevel biological contact oxidation reactor sewage treatment device

A technology of sewage treatment equipment and oxidation reactor, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problem of reducing the effect of microorganisms on sewage purification and reducing the treatment efficiency of sewage equipment. , increase power consumption and other issues, to achieve the effect of simple structure, reasonable design, convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

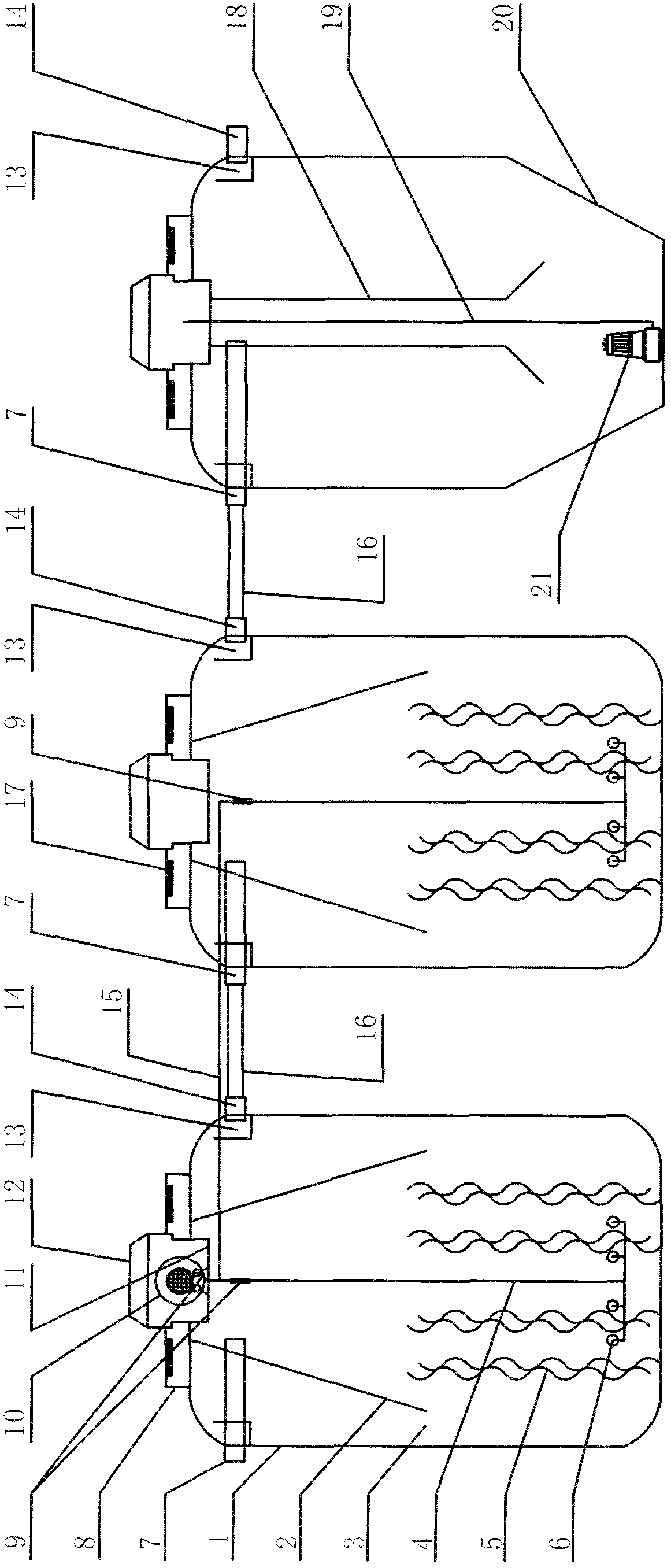

[0028] as attached figure 1 As shown, a multi-stage biological contact oxidation reactor sewage treatment equipment of the present invention is composed of a biological contact oxidation tank, a sedimentation clarifier tank, a packing system, an aeration system, a sludge discharge system and an automatic control system. The biological contact oxidation tank is composed of 2 or more tanks, and each tank is composed of a cylindrical outer tank 1 and a truncated conical inner tank 2, and the inner tank 2 and the outer tank 1 pass through the gap between them. The annular diversion slot 3 conducts. Each biological contact oxidation tank body is provided with a floating type imitation water grass biological filler system 5 . The sedimentation and clarification tank is composed of one tank. The lower part of the tank is an inverted cone-shaped mud collection area 20. The axial center of the tank is a vertical flow pipe 18. The submersible sewage pump 21 for mud discharge is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com