Rapid glycosylation method for modifying egg white protein

An egg white protein and glycosylation technology, applied in the field of modified egg white protein, can solve the problems of high energy consumption and long time required, and achieve the effects of low energy consumption, improved emulsion stability and small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

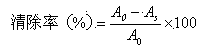

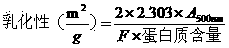

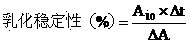

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: A method for rapid glycosylation modification of egg white protein, the steps are as follows:

[0021] (1) Preparation of protein-sugar solution: Prepare egg white protein into a 1% aqueous solution, stir for 30 minutes at 15-30°C, add glucose to the protein solution at a mass ratio of egg white protein: glucose of 1:1, and adjust the pH 8.0, fully stir until the glucose is dissolved and the solution is uniform;

[0022] (2) Spray drying: Spray-dry the above protein-sugar mixture to obtain protein-sugar mixed dry powder, the inlet air temperature is 160-169°C, and the outlet air temperature is 75-85°C;

[0023] (3) Humidity adjustment: place protein-sugar dry powder in a glass desiccator with KI saturated solution to balance the humidity to 65%;

[0024] (4) Microwave treatment: put the humidity-adjusted sample into the microwave field for reaction, set the power to 640W, and the time to 25min, and the modified egg white protein can be obtained;

[0025] (...

Embodiment 2

[0028] Example 2: A method for rapid glycosylation modification of duck egg albumin, the steps are as follows:

[0029] (1) Preparation of protein-sugar solution: Prepare duck egg white protein into a 1% aqueous solution, stir for 30 minutes at 15-30°C, add glucose to the protein solution at a mass ratio of egg white protein: glucose of 1:1, and adjust the pH 8.0, fully stir until the glucose is dissolved and the solution is uniform;

[0030] (2) Spray drying: Spray-dry the above protein-sugar mixture to obtain protein-sugar mixed dry powder, the inlet air temperature is 160-169°C, and the outlet air temperature is 75-85°C;

[0031] (3) Humidity adjustment: place protein-sugar dry powder in a glass desiccator with KI saturated solution to balance the humidity to 65%;

[0032] (4) Microwave treatment: put the humidity-adjusted sample into the microwave field for reaction, set the power to 640W, and the time to 20min, and the modified duck egg white protein can be obtained; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emulsion stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com