Light source adopting LED chip packaging technology

An LED chip and technology technology, applied in the field of LED optics, can solve the problems of the heat of the LED chip cannot be released in time, it is not easy to illuminate the reflector cup, and the cost of optical components is increased, so as to facilitate development and application, increase the number of chips, and increase the area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

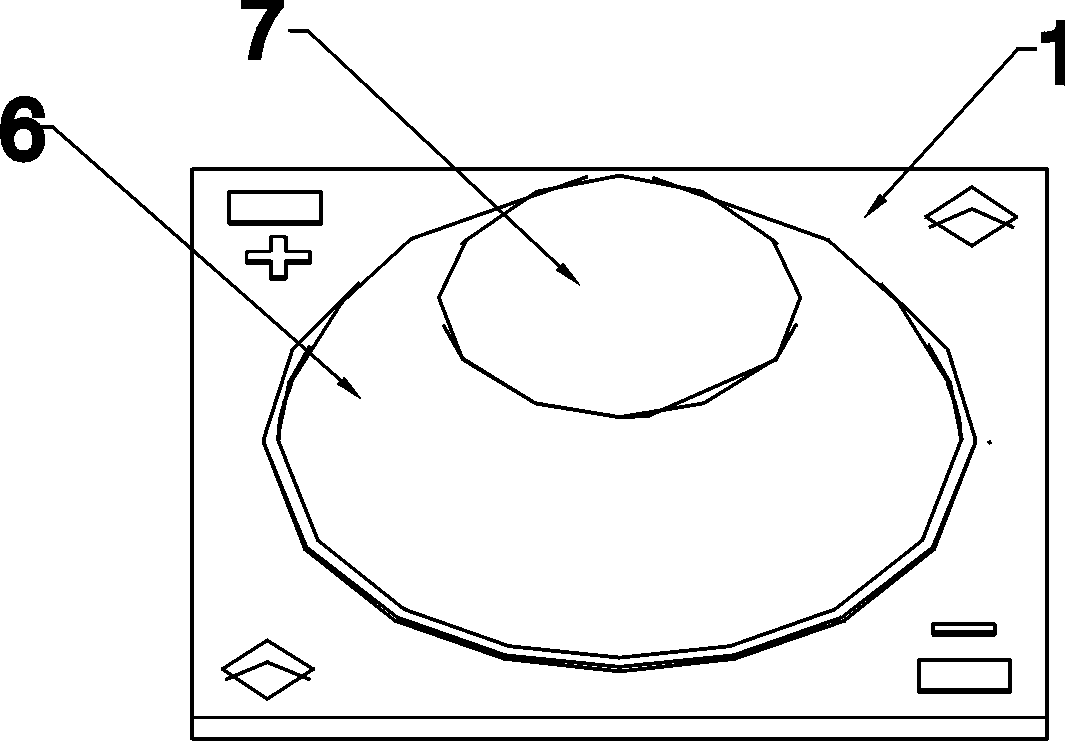

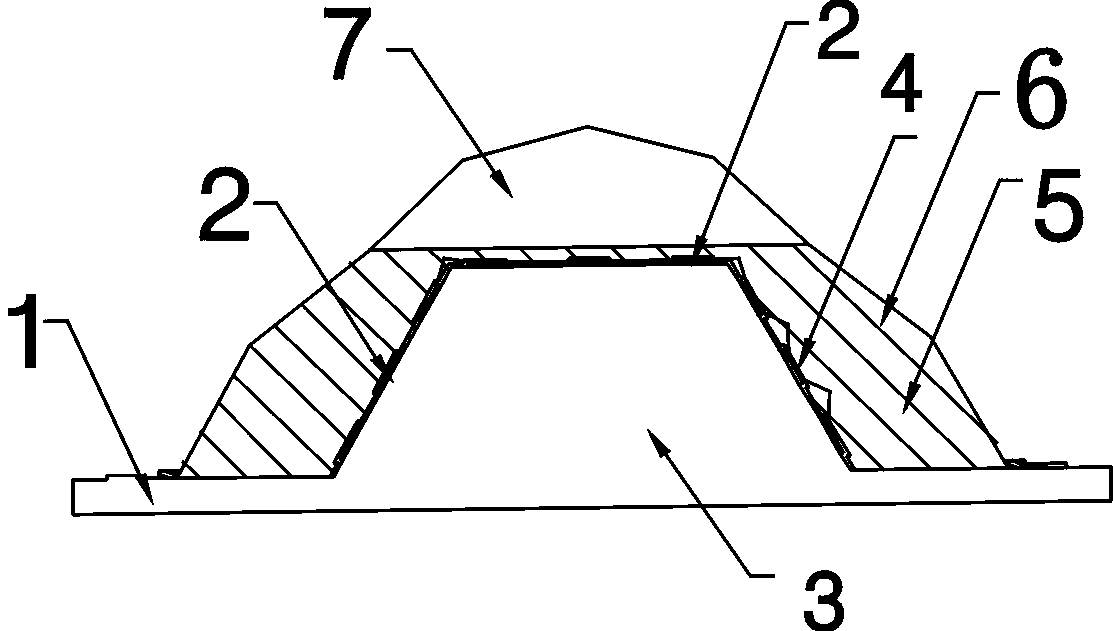

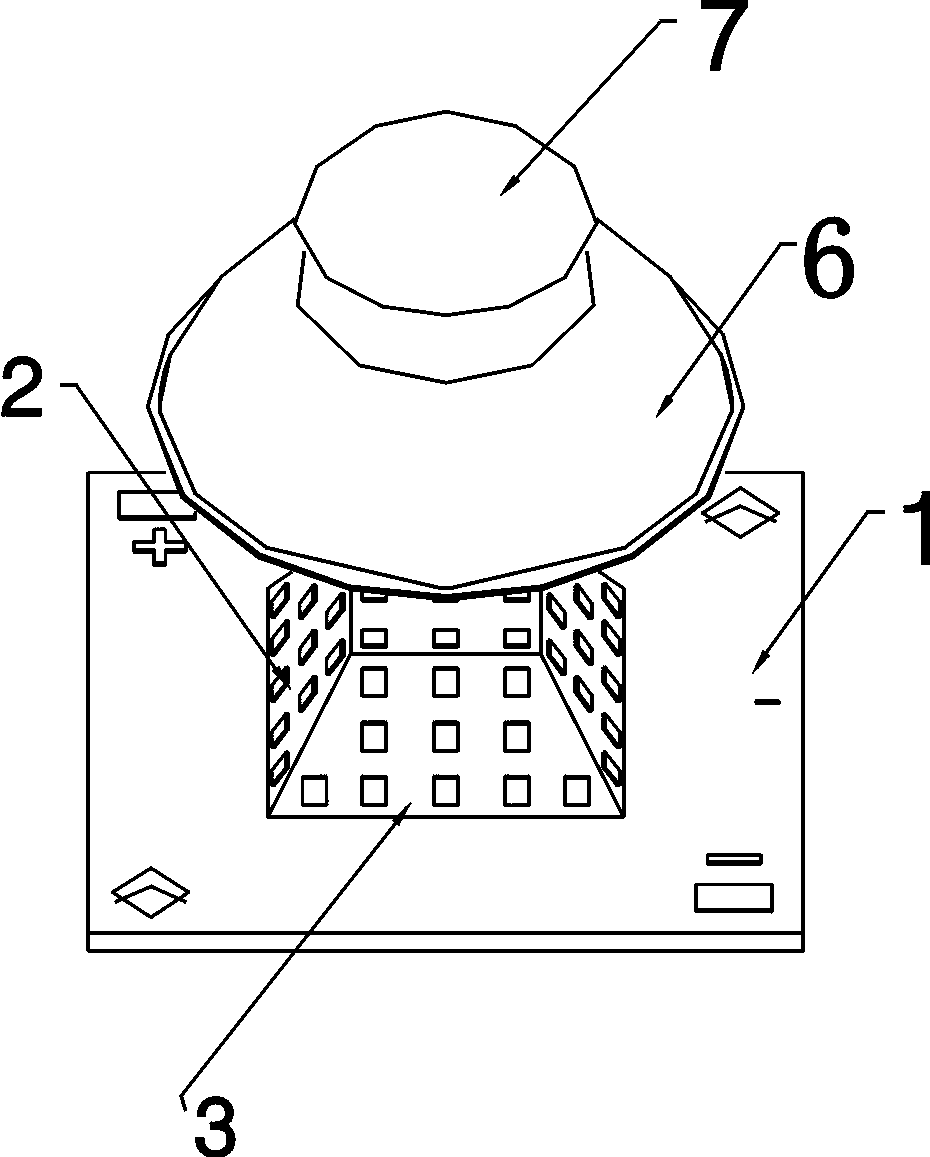

[0035] Embodiment 1: as Figure 1-4 As shown, a light source with LED chip packaging technology includes a copper substrate 1 and an LED chip 2. There is a raised portion 3 in the center of the copper substrate 1, and several LED chips 2 are fixed on the surface of the raised portion 3. The LED chip 2 is sequentially covered with a protective adhesive layer 4, a transparent filling adhesive layer 5, and a fluorescent powder adhesive layer 6 covering the entire raised portion 3, and an optical lens 7 is fixedly connected to the raised portion 3 covered by the above-mentioned adhesive layer. on top.

[0036] Specifically: the convex height part 3 is covered with LED chips 2, and each LED chip is connected with a gold wire. There are three layers of silica gel layers on the LED chip 2. From the inside to the outside, the protective adhesive layer 4, the transparent filling adhesive layer 5, and the fluorescent Powder layer 6. Phosphor glue layer is a silicone layer containing p...

Embodiment 2

[0041] Example 2: see Figure 7 , the difference from Embodiment 1 is that the optical lens 7 is a concave free-form surface.

Embodiment 3

[0042] Embodiment 3: see Figure 8 , The difference from Embodiment 1 is that the optical lens 7 is an outer irregular convex bead point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com