Movable integrated organic waste-gas processing apparatus

A technology of organic waste gas and treatment device, which is applied in the directions of air quality improvement, combustion method, lighting and heating equipment, etc., can solve the problems such as the inability to regenerate and reuse the adsorbent, the treatment of waste gas from unfavorable environmental accidents, and the increase of operating costs, so as to reduce the Weight and equipment volume, saving operating energy consumption, and the effect of small pipeline resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in combination with specific embodiments.

[0026] In the present invention, the movable integrated organic waste gas treatment device is arranged on the walking support ( figure 1 The walking bracket is not shown in the figure), the organic waste gas treatment device can be moved according to needs, for example: when an organic waste gas leakage accident occurs in a chemical plant, the walking bracket can be pushed to move to the emergency accident site, or the organic waste gas treatment device can be moved to the emergency site. On the means of transport, move to the scene of the emergency accident via the means of transport, the organic waste gas treatment device is more convenient and quick to move under the action of the walking bracket;

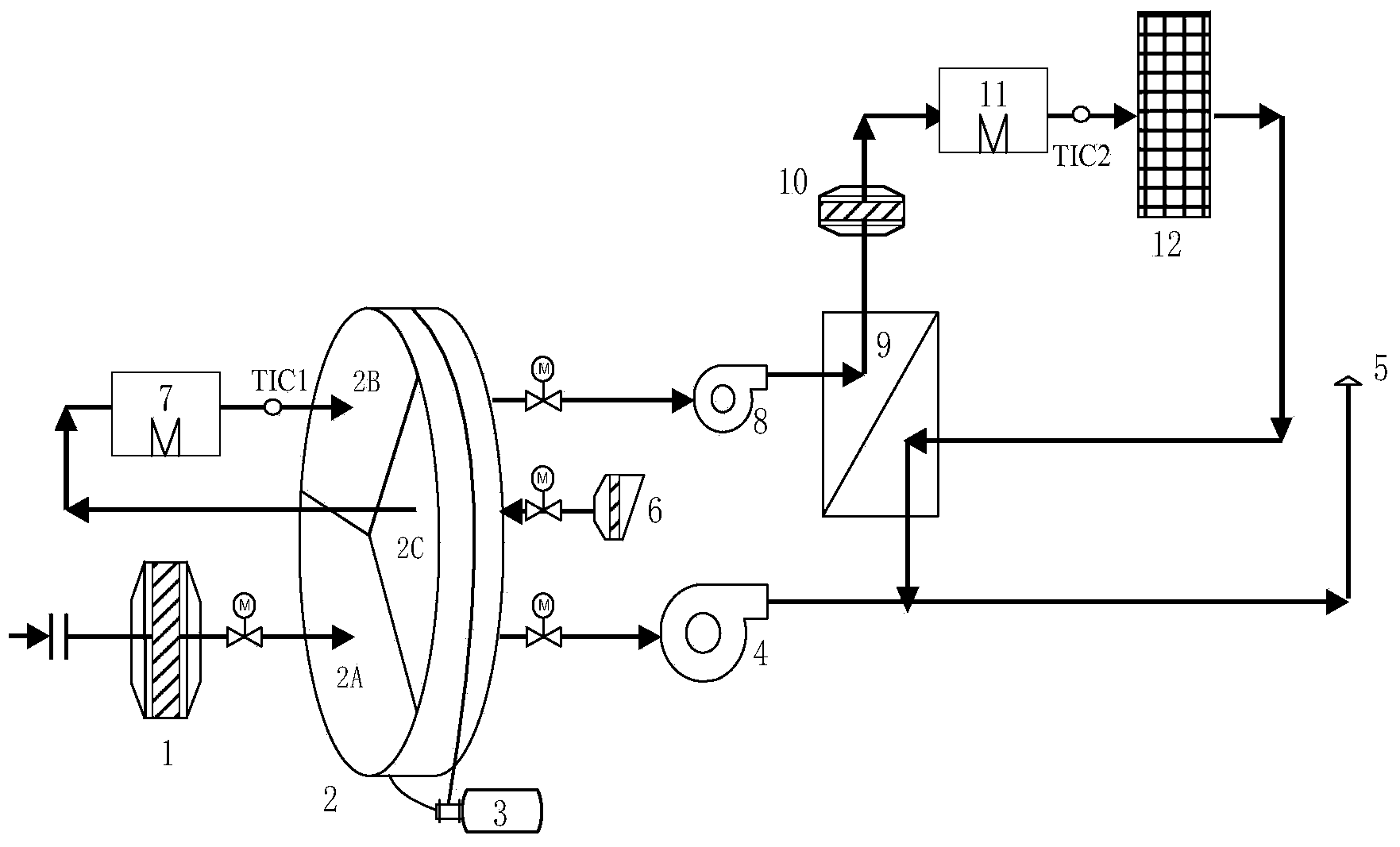

[0027] combine figure 1 , the present invention, an integrated organic waste gas treatment device, mainly includes an adsorption unit, a catalytic oxidation unit a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap