Steel ladle capping heat-preservation method

A technology of ladle and cover, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve the problems of cycle mismatch, high energy consumption, low temperature of turnover ladle lining, etc., to reduce consumption and improve internal The effect of reducing the lining temperature and reducing the tapping temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

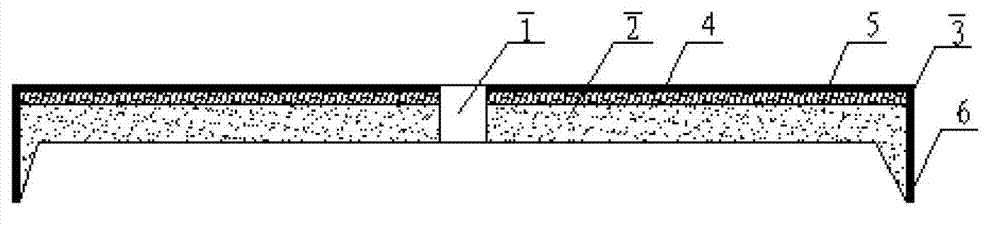

[0013] 1. Enhancing the thermal insulation performance of the cover 5: making the thermal insulation and baking cover 5, adding a layer of heat-insulating material 4 between the refractory knotting material 2 and the steel shell 3, and extending the cover 5 with heat-insulating refractory fiber felt 300mm in diameter, increase the cover skirt 6, so that the cover 5 can seal the mouth of the ladle.

[0014] 2. Adjust the ladle turnover process: cover all the ladles that have withdrawn from the turnover and keep them warm for 3 hours, then put the ladle into the turnover sequence. When cleaning the steel slag at the nozzle, one ladle is forcibly withdrawn for heat preservation to speed up the turnover of the ladle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com