Preparation method and application of octahedron-shaped cobaltosic oxide anode material for lithium ion battery

A technology of tricobalt tetroxide and lithium ion batteries, which is applied in battery electrodes, cobalt oxide/cobalt hydroxide, circuits, etc., can solve the problem of low electron transfer rate lithium ion insertion/extraction rate, cycle performance and rate performance difficult to meet practical needs and limitations Lithium-ion battery performance and other issues, to achieve the effects of simple and controllable reaction conditions, improved cycle stability, and buffer volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 4.40 g CoCl 2 ·6H 2 O and 1.42 g triblock copolymer HO(CH 2 CH 2 O) 106 (CH 2 CH(CH 3 )O) 70 (CH 2 CH 2 O) 106 Add H (F127) into 30 mL of ethanol, stir to dissolve, and reflux at 100 °C for 7 hours. After aging the obtained sol at 66°C for 2 days, heat at 125°C for 15 minutes, and heat-treat the obtained sol at 430°C for 2 hours in an air atmosphere to obtain octahedral cobalt tetroxide sample.

[0019] BET test shows that the specific surface area of this cobalt tetroxide sample is 45 m 2 / g, figure 1 The scanning electron micrograph of the cobalt tetroxide sample produced for this embodiment shows that the shape of the sample is a regular octahedral shape, and the side length of the octahedron is in the range of 0.5-1 um. figure 2 The transmission electron micrograph of the cobalt tetroxide sample produced in this embodiment shows that the inside of the sample has an obvious porous structure.

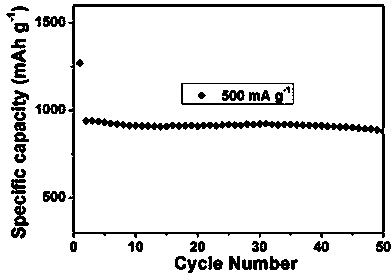

[0020] The cobalt tetroxide sample produced in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com