Novel converter magnesia carbon brick and preparation method thereof

A converter magnesia-carbon brick and magnesia-carbon brick technology, which is applied in the field of refractory materials, can solve the problems of thinning profit of converter magnesia-carbon bricks, too late to eliminate, waste of recycled materials, etc., so as to improve utilization, reduce production pressure, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

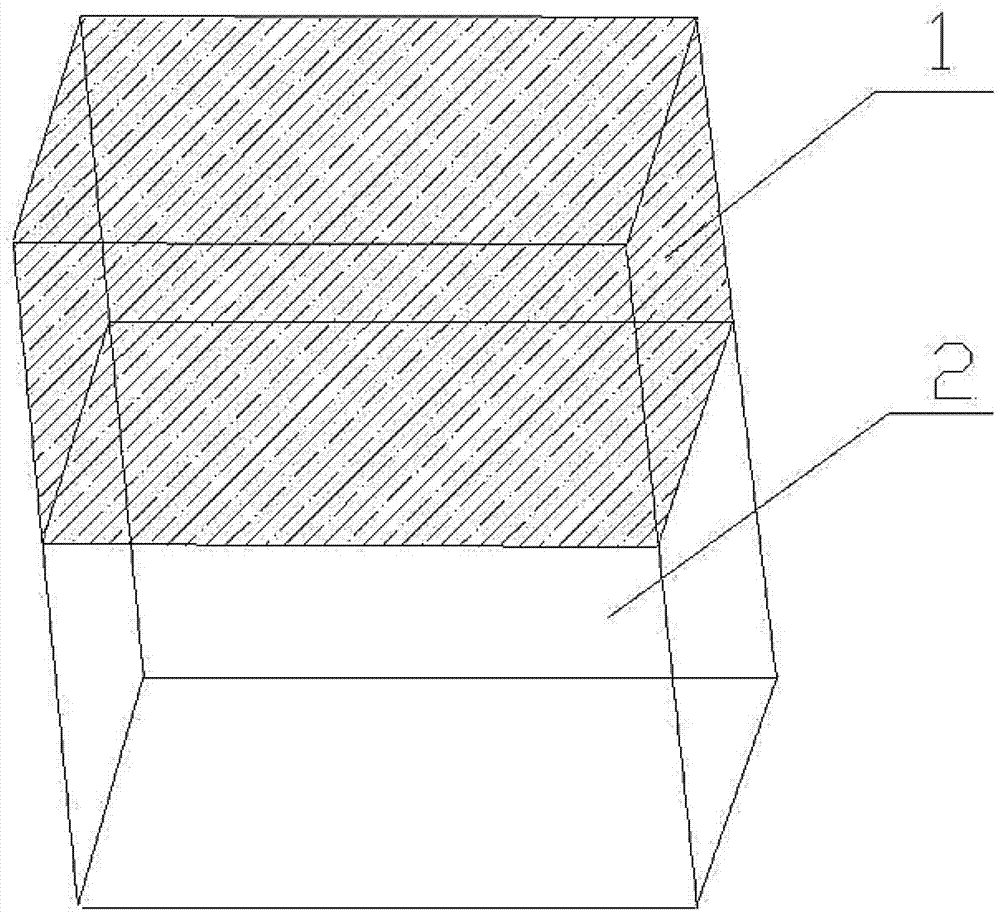

Image

Examples

preparation example Construction

[0037] The preparation method of novel converter magnesia carbon brick of the present invention comprises the steps:

[0038] 1) Sorting: Sorting the recycled materials of magnesia carbon bricks, removing the metamorphic layer and surface impurities of the recycled materials;

[0039] 2) Crushing: The selected regenerated materials are crushed to ≤12mm and then subjected to magnetic separation to remove iron mixed in the regenerated materials; and then sieved to remove powders of ≤1mm.

[0040] 3) Heat treatment: heat and dry the regenerated material treated in step 2) at a heating rate of 8~15°C / min, heat it up to 350°C and keep it warm for 6~10h, choose MgO≥75%, SiO 2 ≤3.6%, CaO≤2.2%, Fe 2 o 3 ≤1.9%, Al 2 o 3 ≤4.5% recycled materials for standby;

[0041] 4) Part of the recycled materials treated in step 3) is further crushed and then screened together with the rest of the recycled materials, and two kinds of recycled materials with particle sizes of 1mm

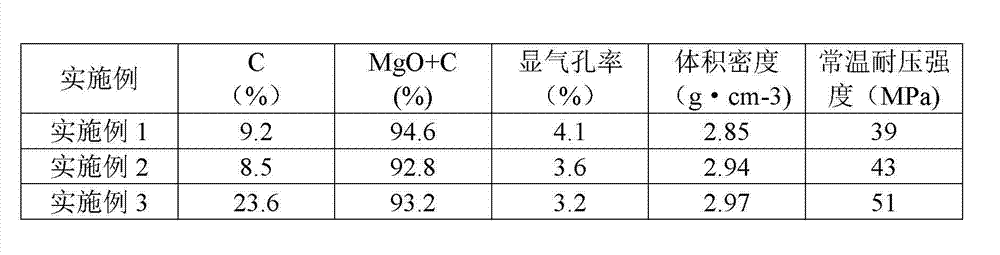

Embodiment 1

[0054] In this example, the new converter magnesia carbon brick is obtained by molding 1 / 4 part of material a and 1 part of material b, wherein in each part of material a, the parts by weight of each component are:

[0055] Fused magnesia, in which the MgO content is ≥ 97.0%, and the fused magnesia with a particle size of 3 mm < particle size ≤ 5 mm: 50 parts by weight; the fused magnesia with a particle size of 0.088 mm < particle size ≤ 3 mm Magnesia: 15 parts by weight; particle size ≤ 0.088mm: 13 parts by weight;

[0056] Graphite: 10 parts by weight;

[0057] Phenolic resin: 2 parts by weight.

[0058] In every part of material b, the parts by weight of each component are:

[0059] Recycled materials that have been sorted, crushed, heat-treated and further crushed, wherein the particle size is 1mm < particle size ≤ 5mm is 35 parts by weight; the particle size is 0 mm < particle size ≤ 1mm is 0 parts by weight;

[0060] Fused magnesia, the MgO content of the fused magne...

Embodiment 2

[0065] In this example, the new converter magnesia carbon brick is formed by 1 part of material a and 1 part of material b, wherein in each part of material a, the parts by weight of each component are:

[0066] Fused magnesia, in the fused magnesia, the MgO content is ≥ 97.0%, and the fused magnesia with a particle size of 3 mm < particle size ≤ 5 mm: 20 parts by weight; the fused magnesia with a particle size of 0.088 mm < particle size ≤ 3 mm Magnesia: 40 parts by weight; particle size ≤ 0.088mm: 25 parts by weight;

[0067] Graphite: 9 parts by weight;

[0068] Phenolic resin: 6 parts by weight.

[0069] In every part of material b, the parts by weight of each component are:

[0070] Recycled materials that have been sorted, crushed, heat-treated and further crushed, wherein the particle size is 1mm < particle size ≤ 5mm is 20 parts by weight; the particle size is 0 mm < particle size ≤ 1mm is 40 parts by weight;

[0071] Fused magnesia, the MgO content of the fused mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com