Hot melt adhesive

A hot-melt adhesive and raw material technology, which is applied in the direction of adhesives, adhesive additives, rosin adhesives, etc., can solve the problems of hot-melt adhesives such as unstable bonding force, inability to guarantee bonding fastness, and poor bonding strength , to achieve the effect of wide range of bonding objects, stable bonding force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

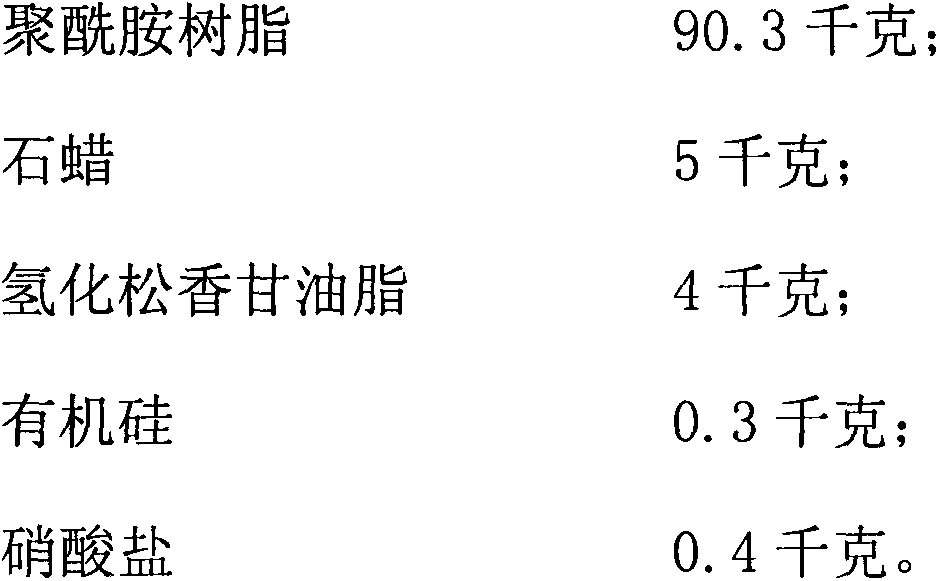

Embodiment 1

[0021] The composition raw material and weight of hot-melt adhesive in the present embodiment are:

[0022]

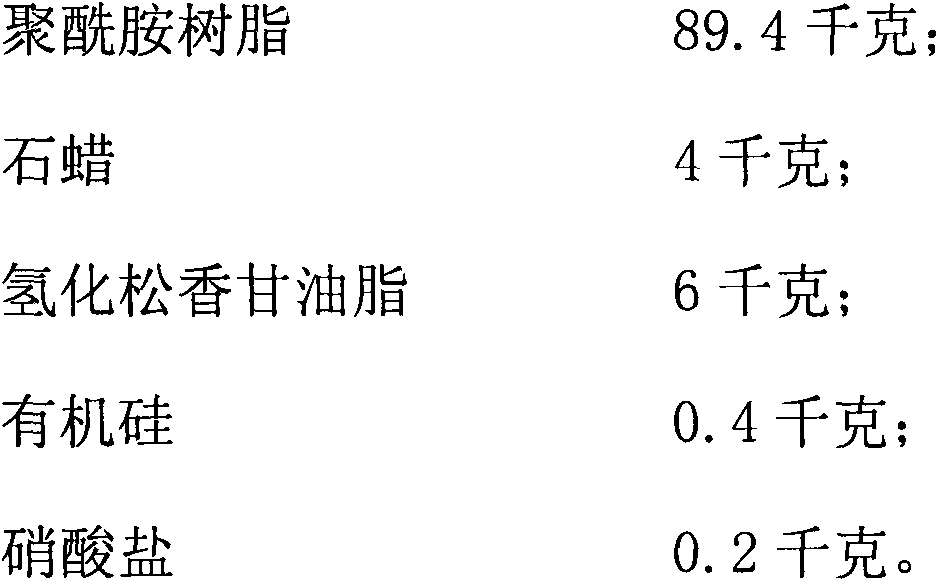

Embodiment 2

[0024] The composition raw material and weight of hot-melt adhesive in the present embodiment are:

[0025]

[0026] The present invention has the following advantages:

[0027] 1. Fast curing speed, good bonding strength and flexibility. Hot melt adhesives can be solidified and bonded within a few tenths of a second to a few seconds, and have the characteristics of melting when heated and sticking when cooled. This enables packagers to use hot melt adhesives to use higher-speed production lines and increase production while reducing defective products, facilitating continuous, automated high-speed operations, and lower costs.

[0028] 2. The cohesive force of the hot melt adhesive is very stable, and it is not affected by the temperature and humidity changes in the morning and evening in the working environment, which ensures the adhesive fastness and eliminates the inherent peeling problem of the packaging machinery.

[0029] 3. Hot melt adhesive does not contain water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com