Heat-resistant fixing structure of travertine plate on floor heater

A technology of floor and slate, applied in the direction of floor, building structure, construction, etc., can solve the problems of crystal surface indurability, shelling, damage, etc., to eliminate hidden quality hazards, improve perception and durability, and avoid black. the effect of spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

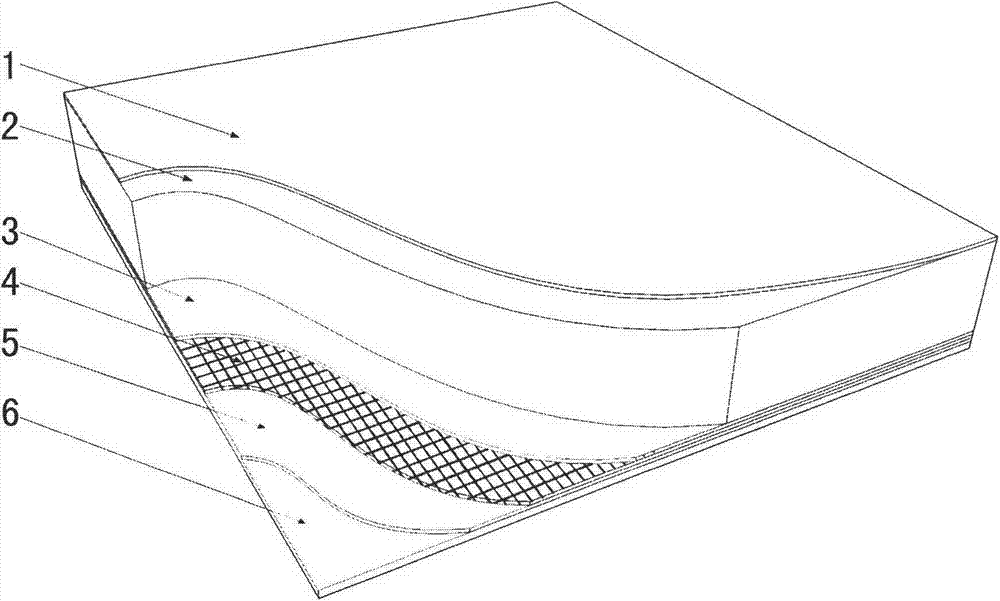

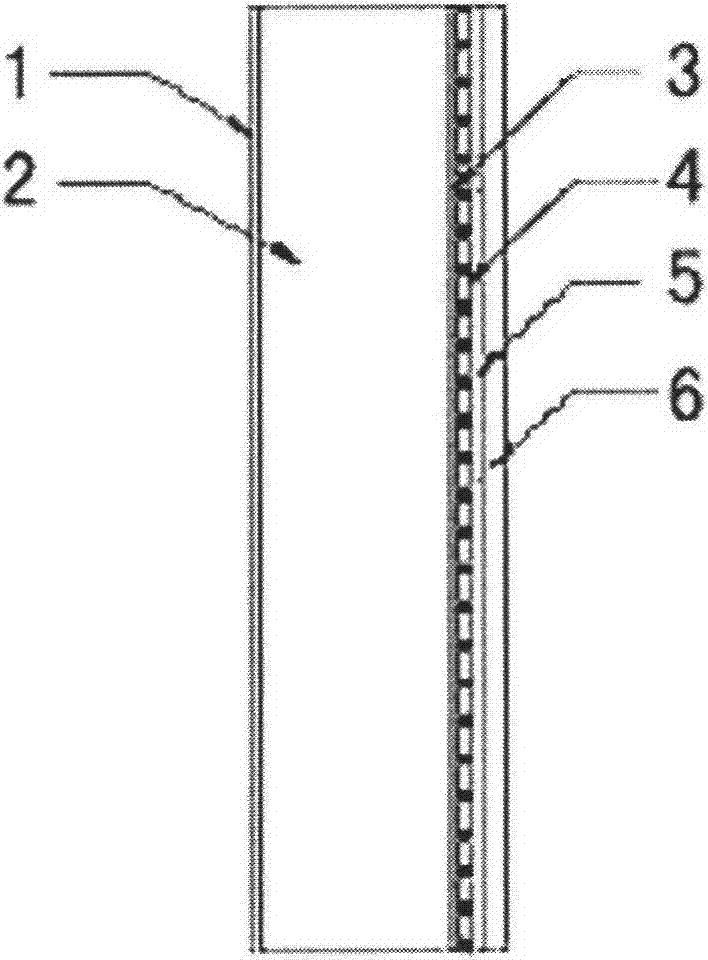

[0019] Example: such as figure 1 , figure 2 As shown, a heat-resistant and durable structure of travertine plates for floor and floor heating, which includes glue stone slurry infiltrated conjunctival layer 1, travertine large slab 2, glue stone slurry infiltrated conjunctival layer 2 3, steel wire mesh 4, glue Stone slurry conjunctival layer 5, gravel sand layer 6, glue stone slurry infiltration conjunctiva layer 1, travertine slab 2, glue stone slurry infiltration conjunctiva layer 2 3, steel wire mesh 4, glue stone slurry conjunctiva layer 5, gravel sand layer 6 The layers are compounded in sequence to form a whole.

[0020] Among them, the thickness of the travertine slab 2 is 25 mm to 30 mm; the steel wire mesh 4 is a galvanized steel wire mesh with a diameter of 1 mm and a mesh size of 10 mm×10 mm; the particle size of the gravel sand in the gravel sand layer 6 is 2 mm to 4 mm. The glue stone slurry penetrates the conjunctival layer 1. The glue stone slurry is mixed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com