A kind of material drying treatment system

A drying treatment and material technology, applied in the field of industrial production, can solve the problems of low drying treatment efficiency, high dust pollution, poor drying effect, etc., and achieve a simple structure, high degree of automation, and short drying cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

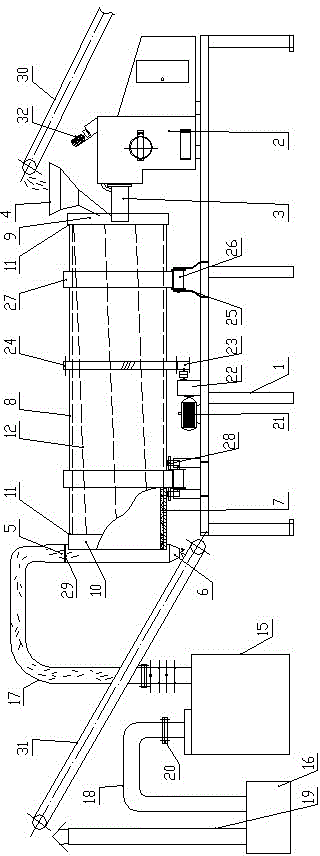

[0024] Such as figure 1 and figure 2 As shown, a kind of material drying treatment system of the present invention comprises frame 1, is provided with burner 2, support device and power drive device on frame 1, is provided with roller on support device rotation, and the transmission of roller and power drive device Connected, the flame nozzle 3 of the burner 2 extends into the drum from one end of the drum, one end of the drum is provided with a feed hopper 4 above the flame nozzle 3, and the upper and lower parts of the other end of the drum are respectively provided with air outlets 5 A dust removal device is connected with the discharge port 6 and the draft port 5. The drum is provided with a strainer 29 at the air outlet 5, and the burner 2 is provided with a screw feeder 32 for fueling the burner 2.

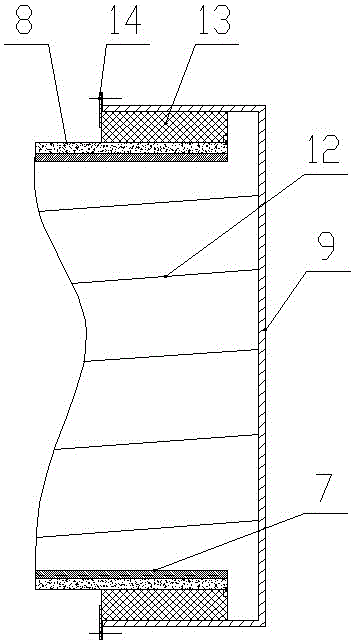

[0025] The drum is inclined downward by 3-5° from one end of the feed hopper 4 to one end of the discharge port 6, preferably 5°. The inner wall of the drum is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com