Rotary low-damping energy-saving drained water splash device

A splash device and low damping technology, which is applied in the field of rotary falling water splash device, can solve the problems of centrifugal splash device, such as short service life, affecting the rotation flexibility of the runner, and difficult to guarantee the reliability of use, so as to reduce The number of production molds is conducive to manufacturing and the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

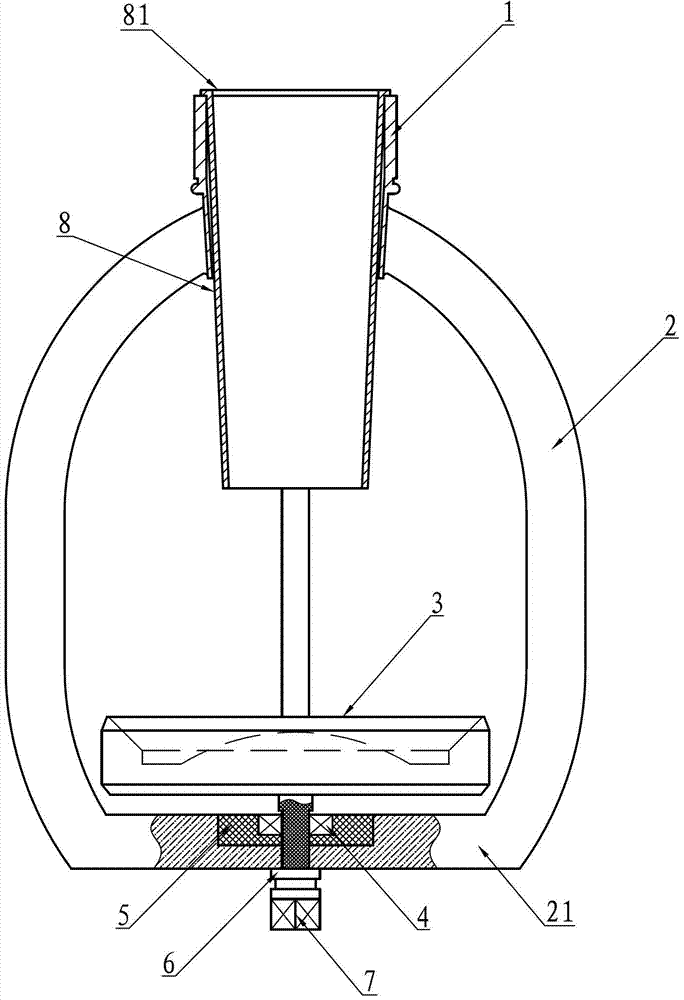

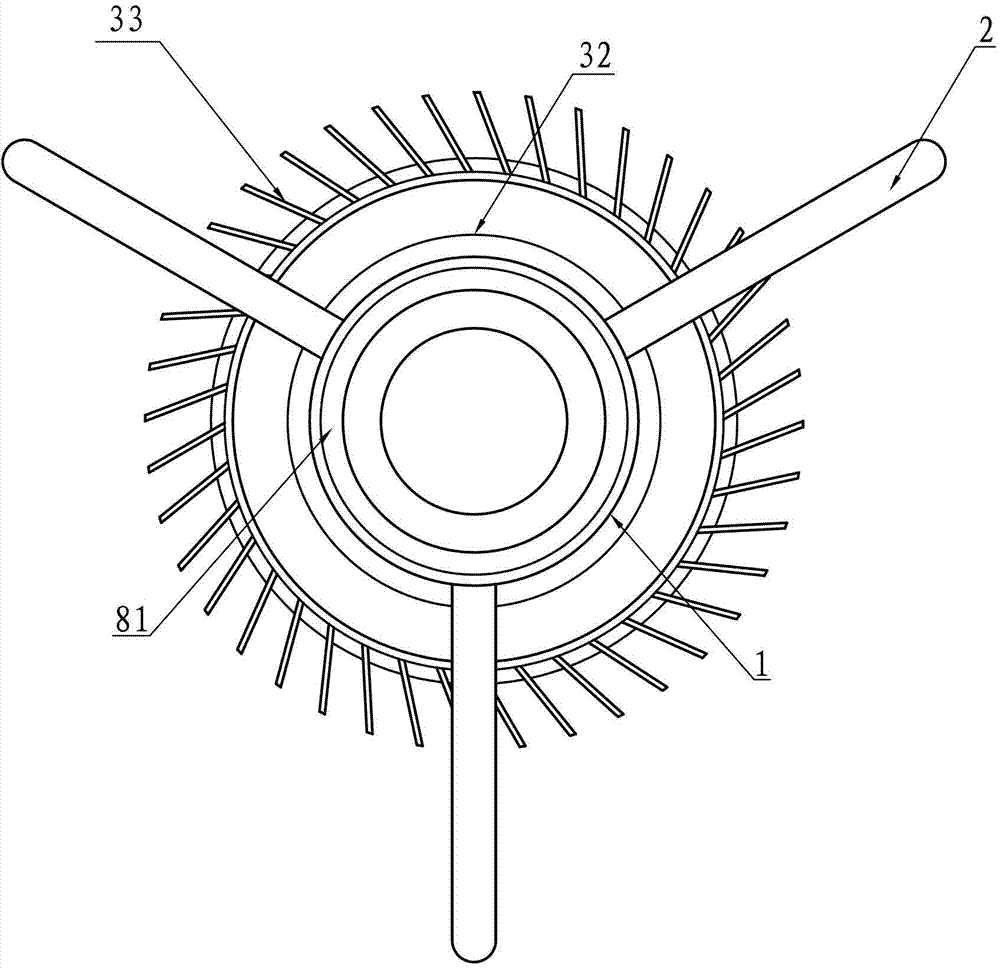

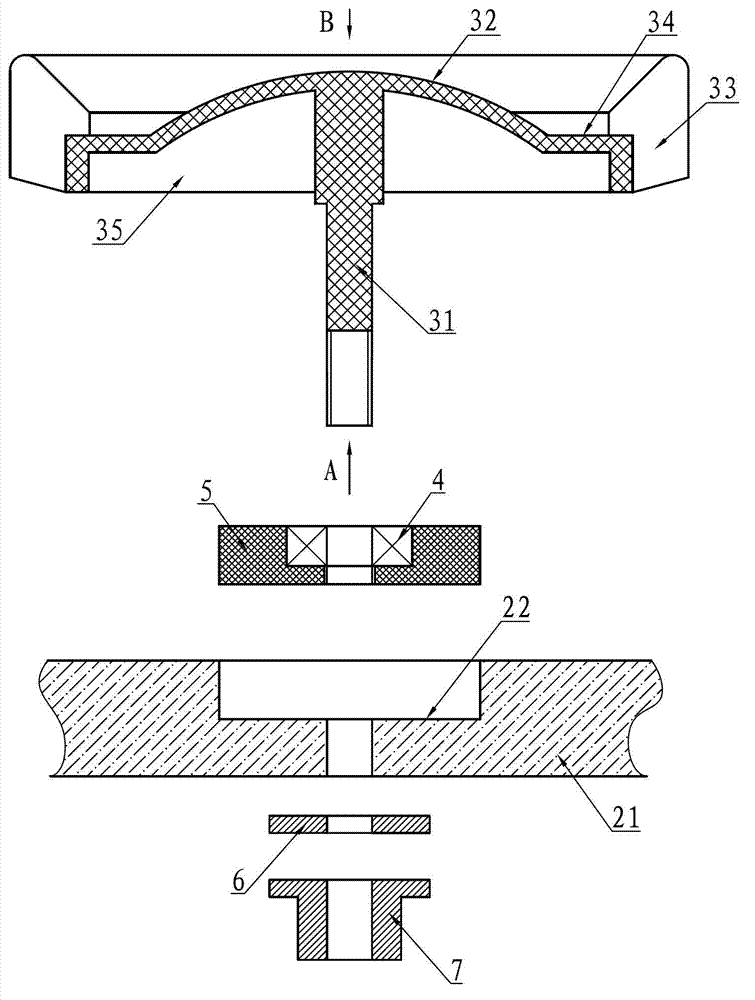

[0021] A rotary low-damping energy-saving falling water splashing device, such as Figure 1~5 As shown: including connecting pipe 1, three-rib support frame 2, splashing water disc 3, rolling bearing 4, bearing seat 5, washer 6, fastening nut 7 and nozzle sleeve 8, the three ribs of the support frame 2 The upper end is evenly fixed on the lower part of the connecting pipe 1, and the lower ends of the three ribs converge into a seat body 21, and a mounting hole 22 is provided on the seat body 21; a conjoined rotating shaft 31 is provided at the center of the lower end of the splashing water rotating disc 3, so that the splashing water The upper end surface of the water rotating dish 3 is a protruding water splashing spherical surface 32, and guide fins 33 with radial angles are evenly arranged on the peripheral edge of the water splashing rotating dish 3, and the guiding fins 33 extend to the splashing water spherical surface 32, adjacent to each other. A water-dividing groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com