Thermistor temperature sensor and manufacturing method thereof

A technology of temperature sensor and thermistor, applied in the direction of thermometer, thermometer, thermometer test/calibration, etc. which are directly sensitive to heat electric/magnetic components, can solve the problem of uneven size of the encapsulation head, poor product encapsulation effect, etc. The problem of reducing the qualified rate of products, etc., can achieve the effect of reducing welding defects, uniform shape and improving sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

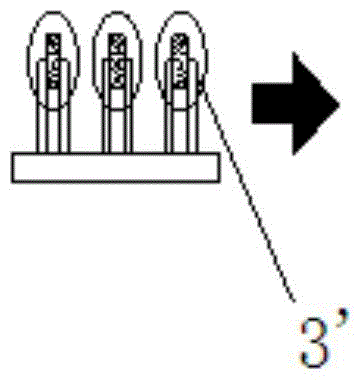

[0051] Such as figure 2 As shown, a thermistor temperature sensor according to the present invention includes an LED bracket 1, and the head side 11 of the LED bracket 1 is provided with a concave portion 111, and after the concave portion 11 is glued and cured by the silver glue 2, the heat is fixed. Sensitive chip 3, an electrode wire 4 is connected between the thermosensitive chip 3 and the other side 12 of the head of the LED bracket 1, and the head of the LED bracket 1 and the periphery of the thermosensitive chip 3 are coated with epoxy The resin encapsulates the case 5 .

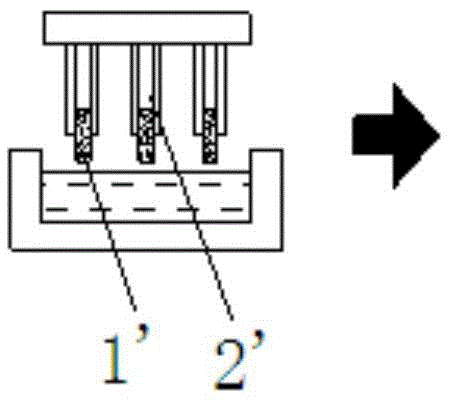

[0052] The manufacture method of the thermistor temperature sensor of the present invention is described in detail below, as shown in FIG. Figure 3a-Figure 3g As shown, the specific steps are:

[0053] (1) Prepare the thermal chip and LED bracket for use, specifically:

[0054] a. If Figure 3a As shown, a number of heat-sensitive chips 3 are arranged and placed on the heat-sensitive chip carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com