Online detection system for surface defects of coldly-rolled aluminum plate and detection method of online detection system

A detection system and defect detection technology, which is applied in the direction of optical detection of defects/defects, can solve the problems of heavy processor transportation load, difficulty in meeting production line stability, high-speed detection requirements and quality assurance, to achieve signal stability and ensure high speed Sexuality and stability, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

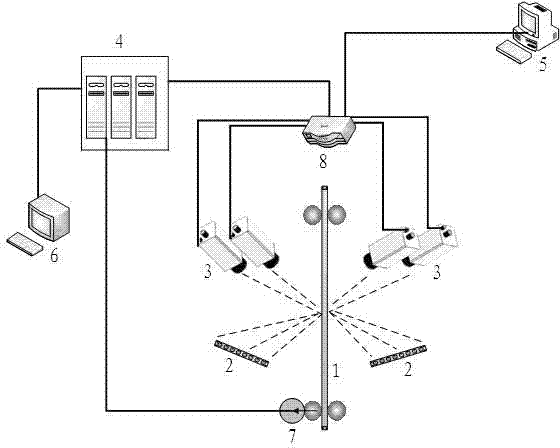

[0035] like figure 1 As shown, the online detection system for surface defects of cold-rolled aluminum sheets mainly includes LED light source 2, aluminum sheet production line 1, high-speed network camera, industrial computer processor array, Ethernet switch, on-site computer 6 and central server 5. The LED light source 2 is installed on the upper and lower sides of the aluminum plate production line 1, and the high-speed camera array 3 is composed of multi-line array CCD cameras, which are installed side by side on the upper and lower sides of the production line 1 horizontally. Each camera is connected to the corresponding industrial computer processor 4 through the GigE interface.

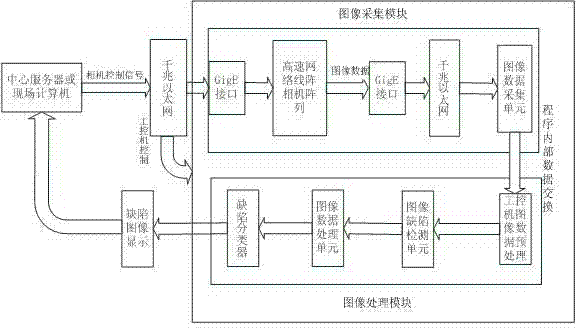

[0036] like figure 2As shown, the industrial computer defect detection system is mainly composed of an image acquisition module and an image processing module. The image acquisition m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com