Novel electric heating tube water-cooled resistor and its preparation process

A technology for water-cooled resistors and electric heating tubes, which is applied in resistors, resistor parts, manufacturing package/shell resistors, etc., can solve the problems of high requirements for water-cooling systems, low requirements for water-cooling systems, and few applications. The effect of fast heat transfer, low scrap rate and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

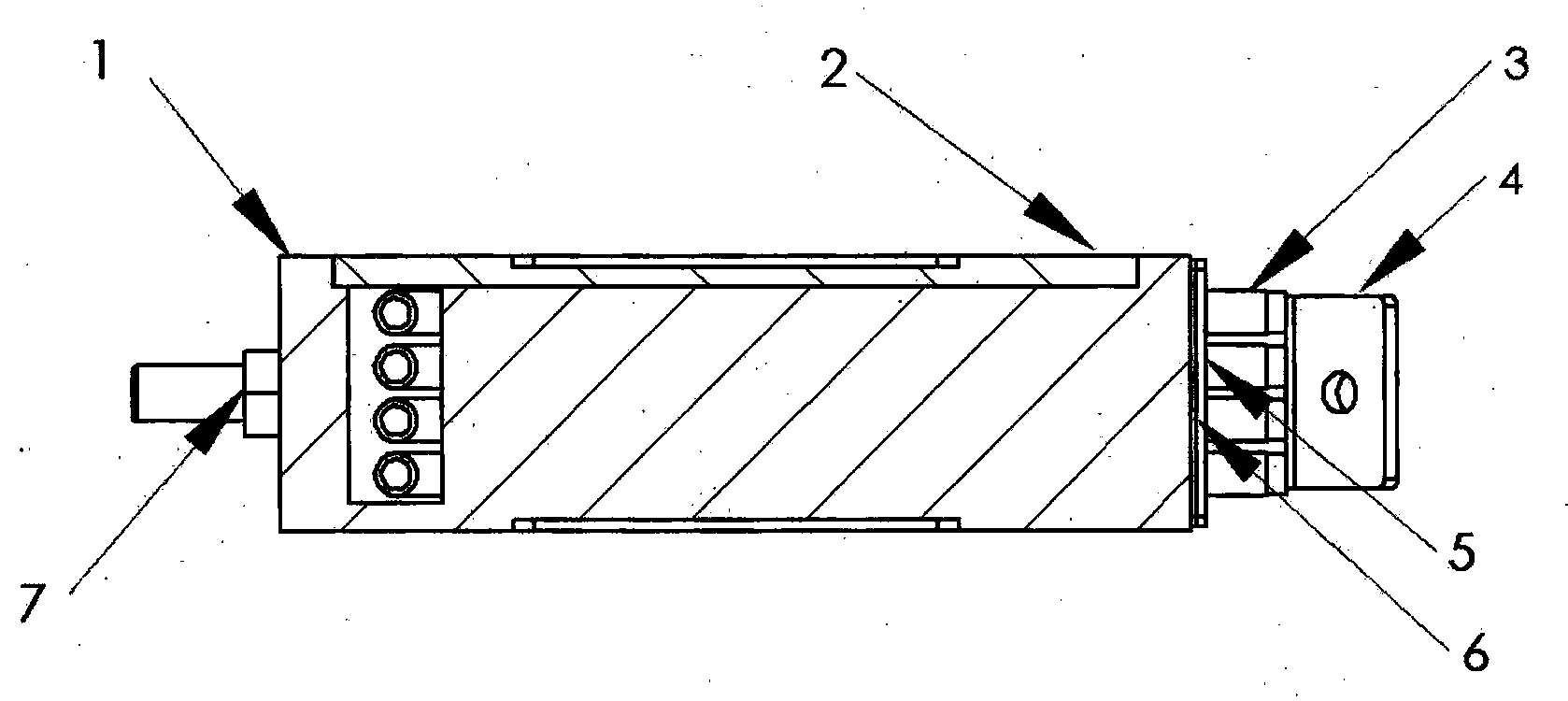

[0018] As shown in Figure 1, it is a schematic structural diagram of the electric heating pipe water-cooled resistor provided by the present invention. The electric heating pipe water-cooled resistor includes an aluminum shell 1, an electric heating tube 3 is arranged inside the aluminum shell 1, and an electric heating tube 3 is arranged on the upper side of the aluminum shell 1. The upper cover plate 2, the left side of the aluminum shell 1 is connected to the pagoda joint 7, the right side of the aluminum shell 1 is provided with a cover plate 5, and the right side of the electric heating tube 3 is connected to the wiring copper bar 4. A silicone pad 6 is provided between the cover plate 5 and the aluminum shell 1 .

[0019] The specific steps of the preparation method of the above-mentioned electric heating tube water-cooled resistor are as follows: put the electric heating tube 3 into a tube shrinking machine to shrink the tube so that the internal parts are closely attach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap