Wafer-level packaging structure and packaging method of image sensor

A wafer-level packaging and image sensor technology, which is applied in the manufacturing of electrical solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background technology that when using the existing wafer-level packaging technology to package the image sensor, at the end of the packaging process, it is necessary to peel off the package cover from the wafer, but how can the package cover be separated from the wafer without damaging the wafer? There is still no effective solution to simply and conveniently peel off the package cover from the wafer.

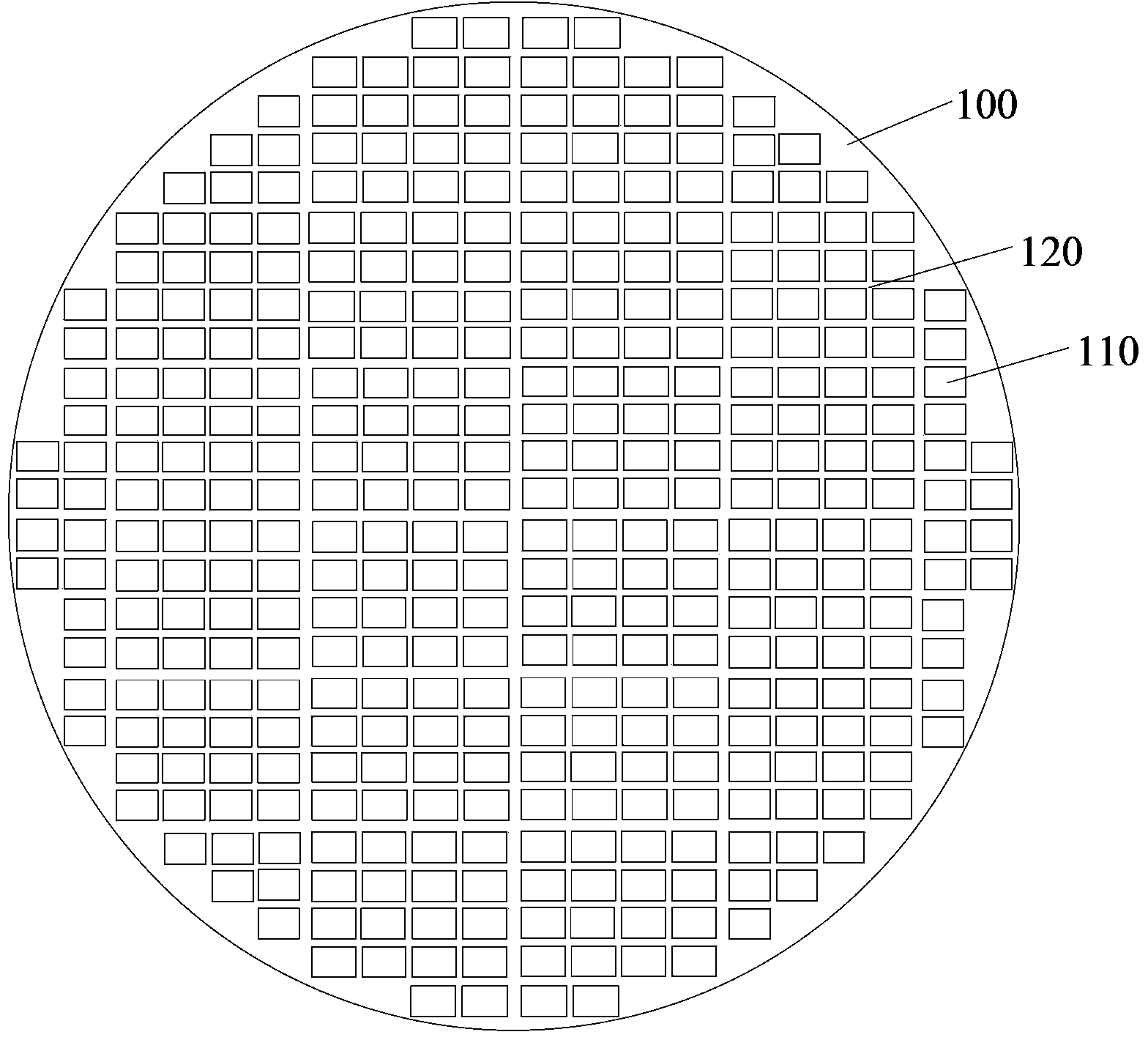

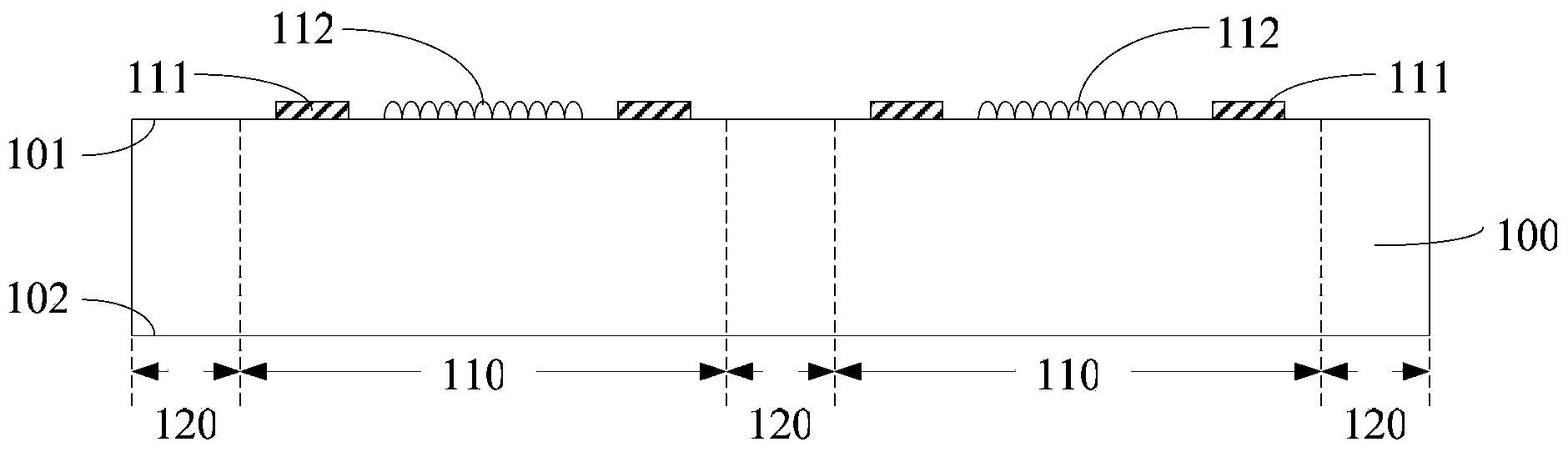

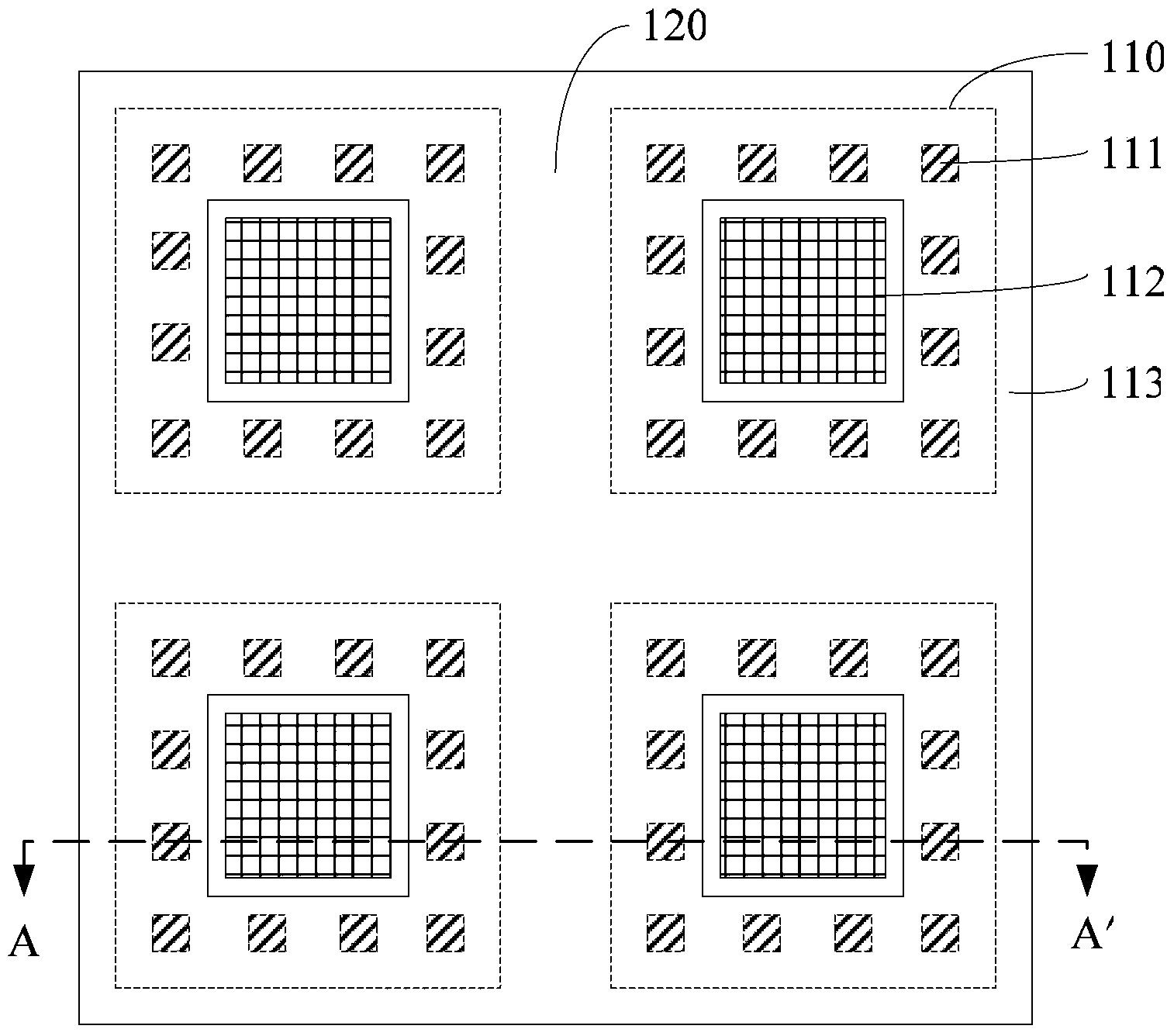

[0030] To this end, the present invention provides a wafer-level packaging structure and packaging method of an image sensor, the wafer-level packaging structure of the image sensor includes: a wafer to be packaged, the wafer to be packaged includes several chip regions and The dicing line area between the chip areas; the bonding pad and the image sensing area located on the first surface of the wafer to be packaged and located in the chip area; the first embankment structure located on the surface of the bonding pad and the surface of the dicing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com