Manufacturing process of drive motor pot base for electric vehicles

A technology for driving motors and electric vehicles, applied in the directions of electric vehicles, motors, and electric components, etc., can solve the problem of poor coaxiality between the stop of the frame and the bearing chamber of the end cover, large radial runout of the main shaft of the power system, and the transmission system of the whole vehicle. Influence and other issues, to meet the needs of small and lightweight, improve competitiveness, and simplify the assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

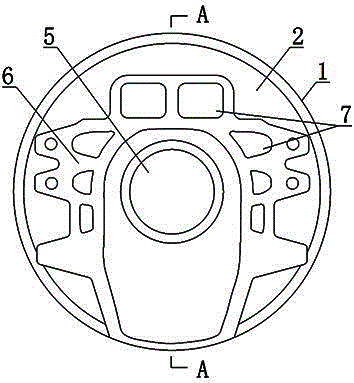

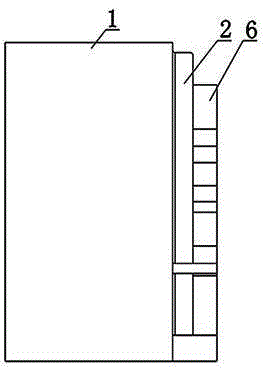

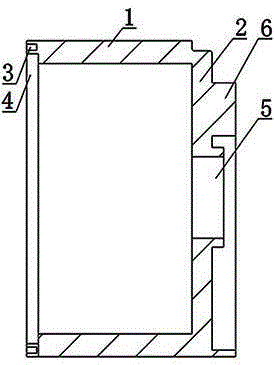

[0022] like Figure 1 ~ Figure 4 As shown in the figure, the drive motor pot base for electric vehicles includes a cylindrical main body 1 and a rear end cover 2 integrally formed with the main body 1. Connecting screw holes 3 are uniformly distributed along the circumferential direction on the front end surface of the main body 1, and the inner surface of the main body 1 The front end is provided with a front stop 4, and the rear end cover 2 is provided with a bearing chamber 5. The machine base and the rear end cover 2 are integrated into one, and the integral processing is adopted, which eliminates the assembly process of the rear end cover 2 and the machine base, simplifies the motor assembly process, improves the motor assembly accuracy, and reduces the system noise

[0023] The outer end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com