Oil-cooled screw air compressor coaxial with motor

An air compressor, oil cooling technology, applied in electrical components, machines/engines, electromechanical devices, etc., can solve the problems of limiting the frequency modulation range of the unit, the speed of the unit should not be too low, affecting the reliability of products, etc., to achieve maintenance-free, Compact mechanism, the effect of eliminating the point of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

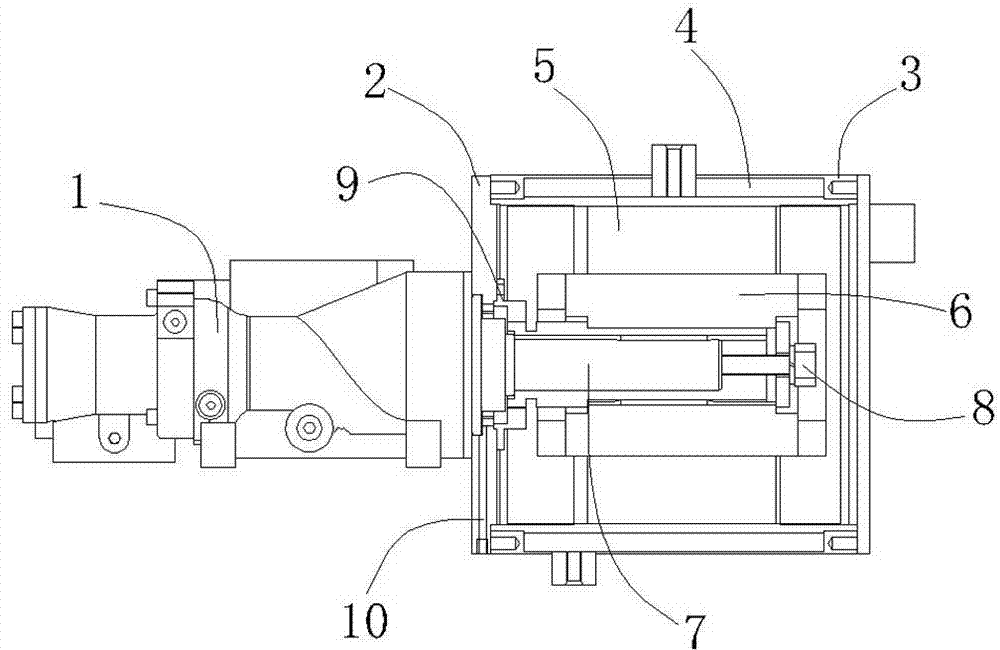

[0012] Such as figure 1 As shown, the oil-cooled screw air compressor coaxial with the motor includes an air compressor main body 1 and a circulating oil system. The tail of the air compressor main body is provided with a body bracket 2, which is centered on the body bracket 2 A motor housing 3 is installed, and a cooling interlayer 4 is arranged on the motor housing 3 .

[0013] The inner wall of the motor housing 2 is provided with a motor stator 5, and the motor housing 1 is provided with a motor rotor 6, and the motor rotor 6 is fastened to the drive shaft 7 of the main engine of the air compressor. thereby forming a unity. In this embodiment, the drive shaft 7 of the air compressor main unit extends into the motor housing 3, and the motor rotor 6 is sleeved on the drive shaft 7 of the air compressor main unit. The drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com