Adaptive architecture solids diverter and comminutor

A technology for pulverizing chamber and solid waste, applied in the direction of grain processing, etc., can solve the problems of large system, troublesome extraction device and difficult management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

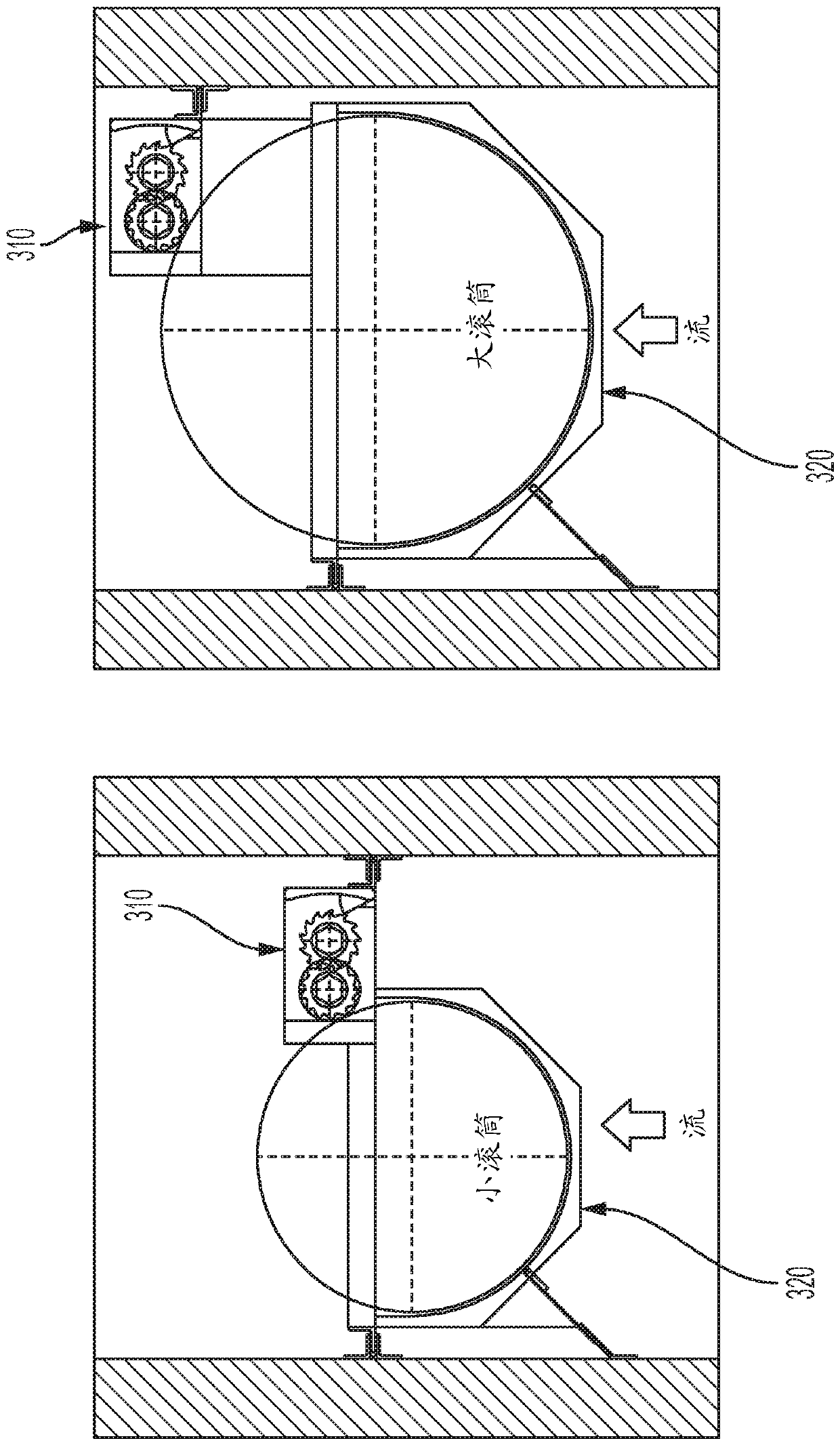

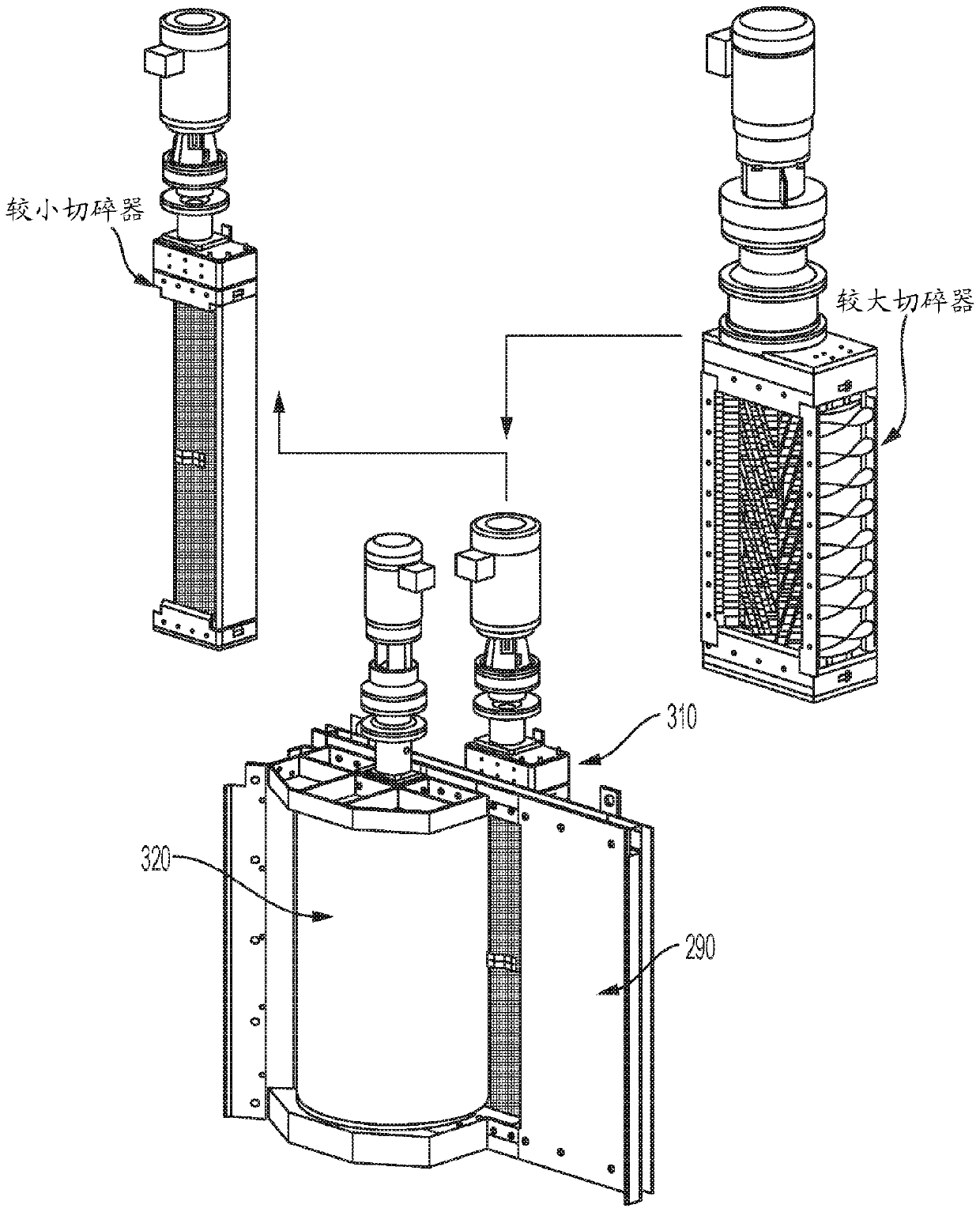

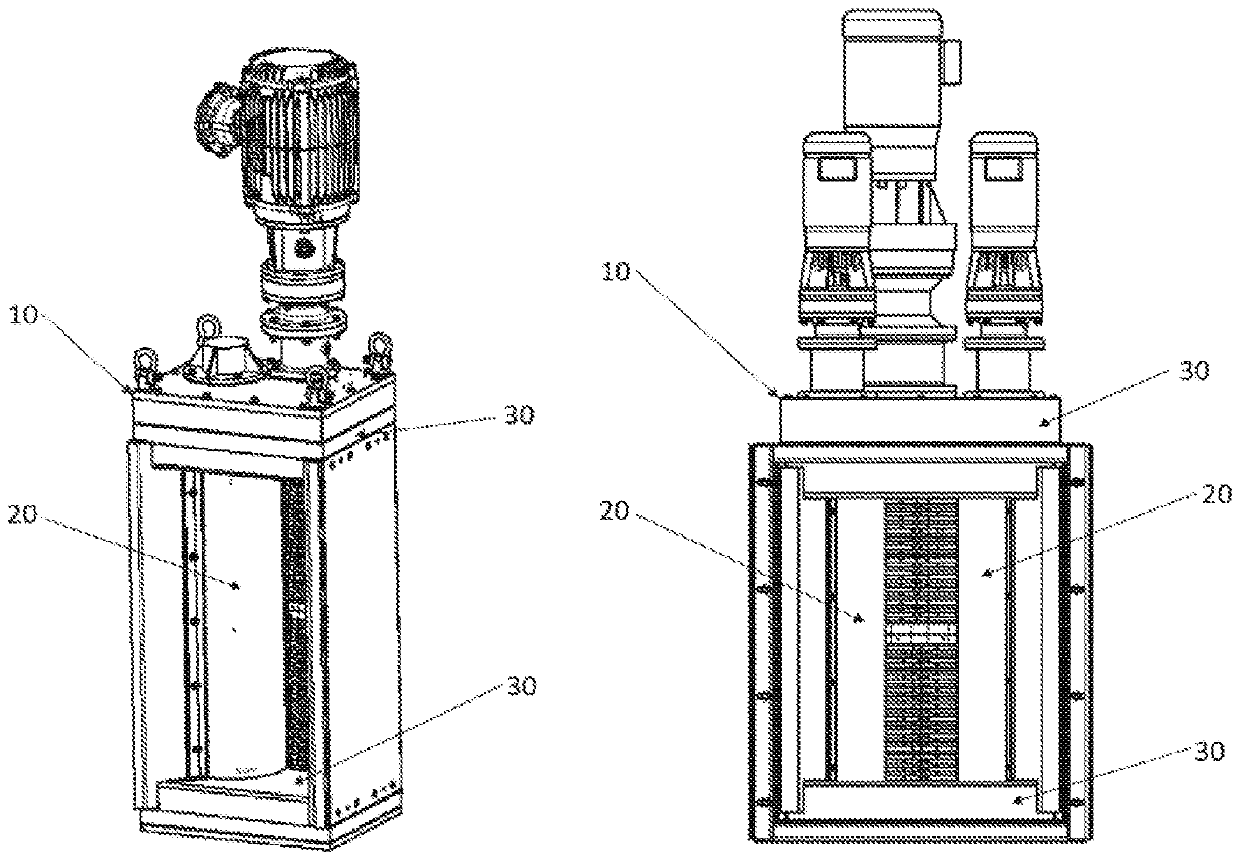

[0047] According to usually shown in Figure 4 In the exemplary embodiment described herein, the Adaptive Structural Solids Splitter and Shredder consists of the following elements: (i) a two-axis rotating cutter stack with staggered cutters and spacers 200; (ii) a bearing, sealed (iii) chopper bottom housing with bearings, seals and cover 220; (iv) chopper drive mechanism 230; (v) Vertically aligned rotating screen drum 240; (vi) screen drum top shell with bearings, seals, shroud and shroud cover 250; (vii) with bearings, seals, cover and shroud 260 (viii) screen drum baffle 270, channel seal 275 and sealing element 330; (ix) screen drum drive mechanism 280; (x) grinder / screen drum interconnect frame 290; and (xi) a grinder / sieve drum mounting frame 300 for attachment to civil structures 305.

[0048] The Adaptive Structural Solids Divider and Pulverizer are mounted vertically with the driver facing upwards and positioned in the mounting frame, which in turn is fastened in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com