Tobacco insect killing, mold prevention, mellowing and quality guaranteeing comprehensive technology method

A tobacco leaf and alcoholization technology, which is applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of unsuitability for direct production of cigarettes, quality defects of tobacco leaves, and deterioration of tobacco leaf quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 implements the comprehensive technical method of the present invention to the southern tobacco leaf warehouse

[0052] To set the feeding port, ventilation port and gas detection system for the sealed tobacco leaf warehouse, the steps are as follows:

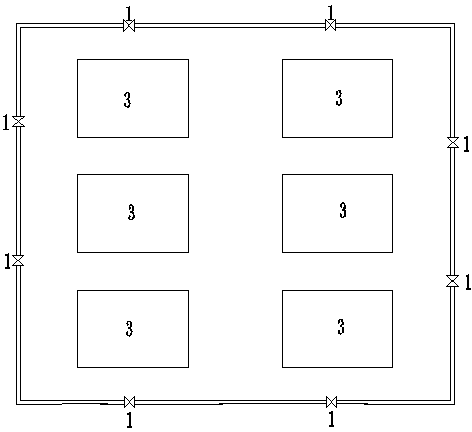

[0053] a. Set up two channels 1 with 30-mesh filter screens on each side of the bottom of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 1 shown). The size of this channel is 30cm×30cm, it is closed when not in use, and can be used for feeding materials or ventilation or filling carbon dioxide gas when it is opened;

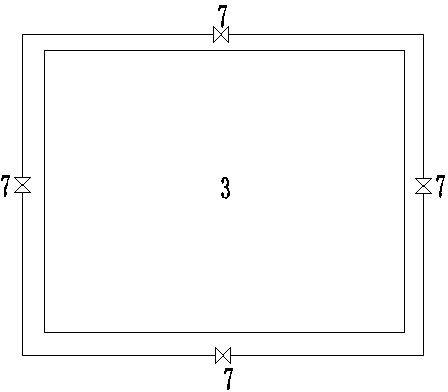

[0054] b. Set a channel 2 with a 30-mesh filter screen on the upper part of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 2 shown). The size of this channel is 30cm×30cm, closed when not in use, and can be used for exhaust when opened;

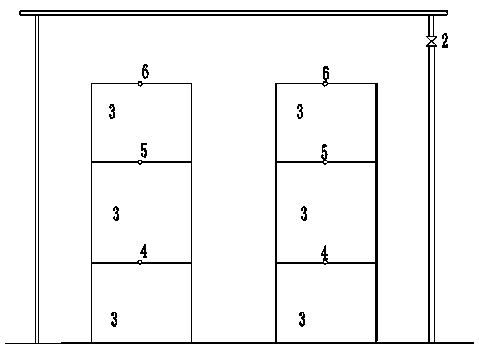

[0055] c. Evenly distribute gas concentration detection points 4, 5, and 6 in the wa...

Embodiment 2

[0077] Embodiment 2 implements the comprehensive technical method of the present invention to northern tobacco leaf warehouse

[0078] To set the feeding port, ventilation port and gas detection system for the sealed tobacco leaf warehouse, the steps are as follows:

[0079] a. Set up two channels 1 with 30-mesh filter screens on each side of the bottom of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 1 shown). The size of this channel is 30cm×30cm, it is closed when not in use, and can be used for feeding materials or ventilation or filling carbon dioxide gas when it is opened;

[0080] b. Set a channel 2 with a 30-mesh filter screen on the upper part of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 2 shown). The size of this channel is 30cm×30cm, closed when not in use, and can be used for exhaust when opened;

[0081] c. Evenly distribute gas concentration detection points 4, 5, and 6 in the wareho...

Embodiment 3

[0103] Embodiment 3 implements the comprehensive technical method of the present invention to the tobacco leaf warehouse in Central Plains

[0104] To set the feeding port, ventilation port and gas detection system for the sealed tobacco leaf warehouse, the steps are as follows:

[0105] a. Set up two channels 1 with 30-mesh filter screens on each side of the bottom of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 1 shown). The size of this channel is 30cm×30cm, it is closed when not in use, and can be used for feeding materials or ventilation or filling carbon dioxide gas when it is opened;

[0106] b. Set a channel 2 with a 30-mesh filter screen on the upper part of the sealed tobacco leaf warehouse to block the passage of insects (such as figure 2 shown). The size of this channel is 30cm×30cm, closed when not in use, and can be used for exhaust when opened;

[0107] c. Evenly distribute gas concentration detection points 4, 5, and 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com