Energy-saving and high-efficiency self-cleaning polymerization process and device

A technology of polymerization device and polymerization process, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical/physical/physicochemical processes, etc. , product quality decline and other problems, to avoid the use of anti-sticking agent, avoid the decline of heat transfer coefficient, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

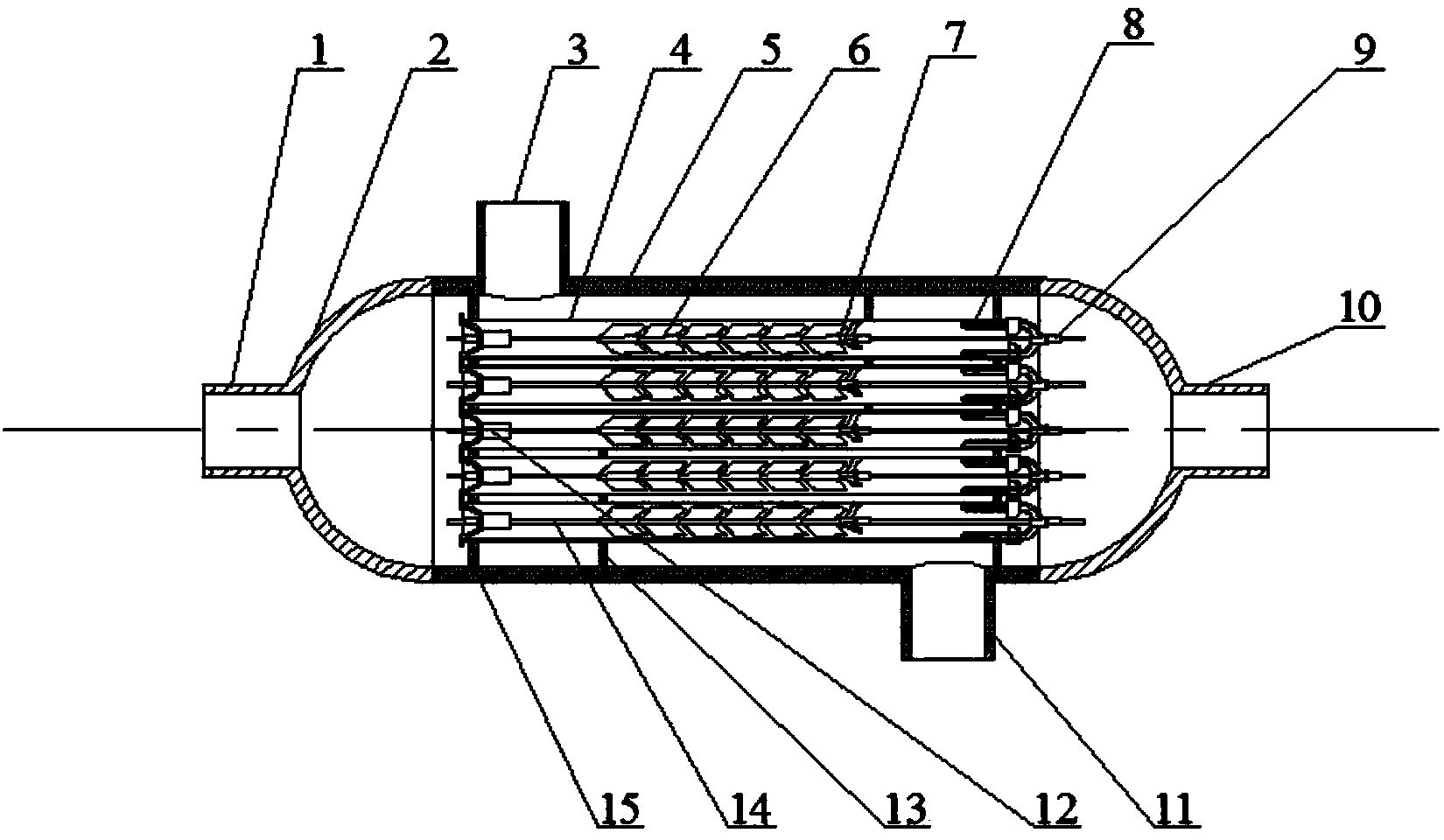

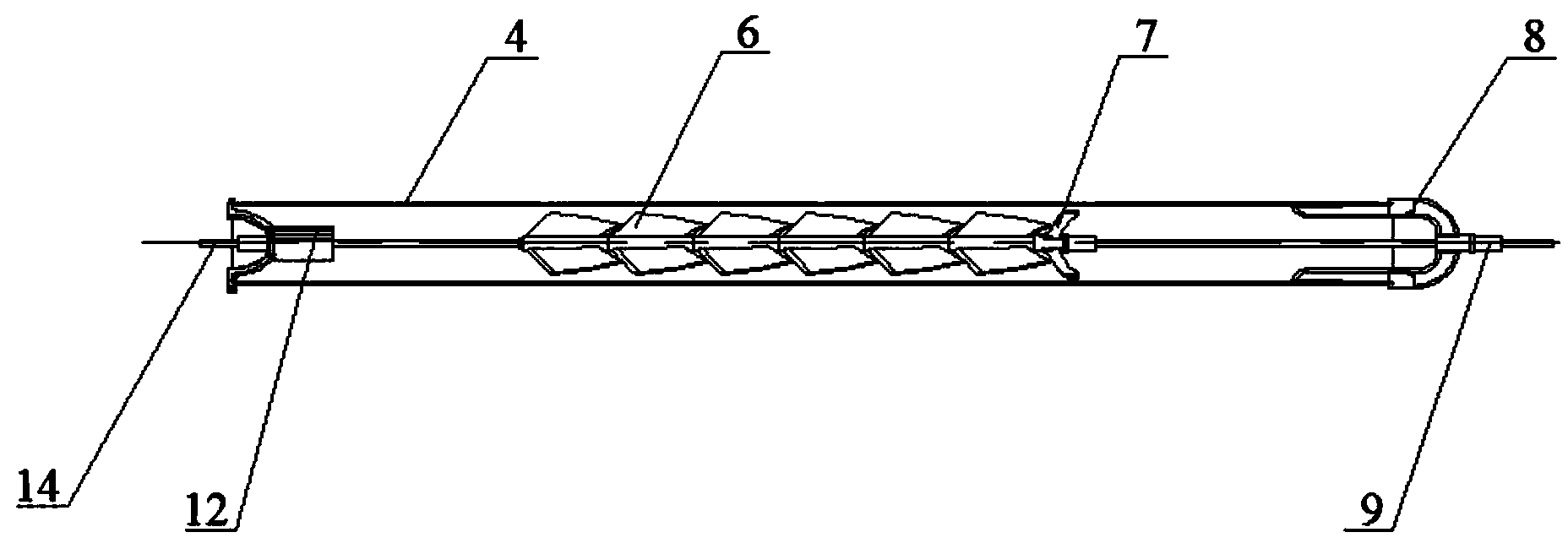

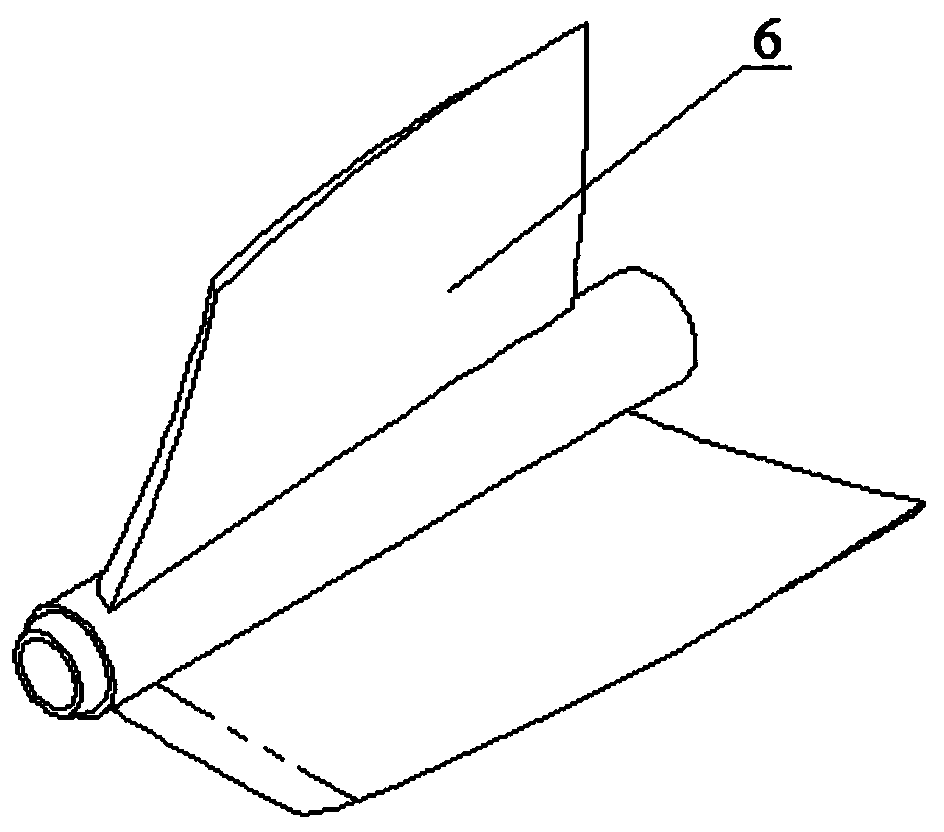

specific Embodiment approach 2

[0036] The water used for batching is sent from the pure water workshop and then added to the high-purity water storage tank. The high-purity water is pumped to the monomer metering tank, and the vinyl chloride monomer is sent to the monomer metering tank by the vinyl chloride workshop. The weighed various additives It flows into the tubes 4 of the tube-and-tube reactor by means of the delivery pump, and the rotor 6 inside the tube 4 is driven to rotate by means of the fluid action, and the turbulent flow formed by the rotation of the rotor 6 is used to realize the cold stirring of the material, and the hot water pump is started after the end. Send hot water into the shell of the reactor, stop the hot water pump when the tube side temperature rises to the reaction temperature, and absorb the reaction heat with cooling water, the polymerization reaction continues, and the material can be discharged when the reaction pressure drops to 0.1-0.15MPa.

specific Embodiment approach 3

[0037] Ethylene is used as a polymerization raw material to flow into the tube 4 of the tube-and-tube reactor through a delivery pump, and the rotation of the rotor 6 in the tube 4 driven by the fluid is used to prevent wall sticking and clogging, and it is added to the shell side of the reactor. Hot water is used to provide the reaction temperature. After a period of reaction time, the polymer slurry flowing out of the reactor tube passes through the flash tank, the gas-liquid separator to the powder dryer, and then granulates.

specific Embodiment approach 4

[0038] Taking the slurry method as an example, when feeding into the reactor, control the hot water on the shell side to ensure that the reaction temperature is 50-70°C and control the feed pressure at 0.5-1MPa when feeding, and add a trace amount of hydrogen at the same time, and use the rotor 6 to rotate The effect makes it fully mixed to achieve the effect of adjusting the relative molecular mass. After the reaction is over, alcohols will be added to another device to remove catalyst residues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com