Macro preparation method of macroscopic three-dimensional graphene aerogel adsorption material used for indoor air purification

A technology of graphene airgel and adsorption materials, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as easy layer accumulation, achieve excellent adsorption performance, easy control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

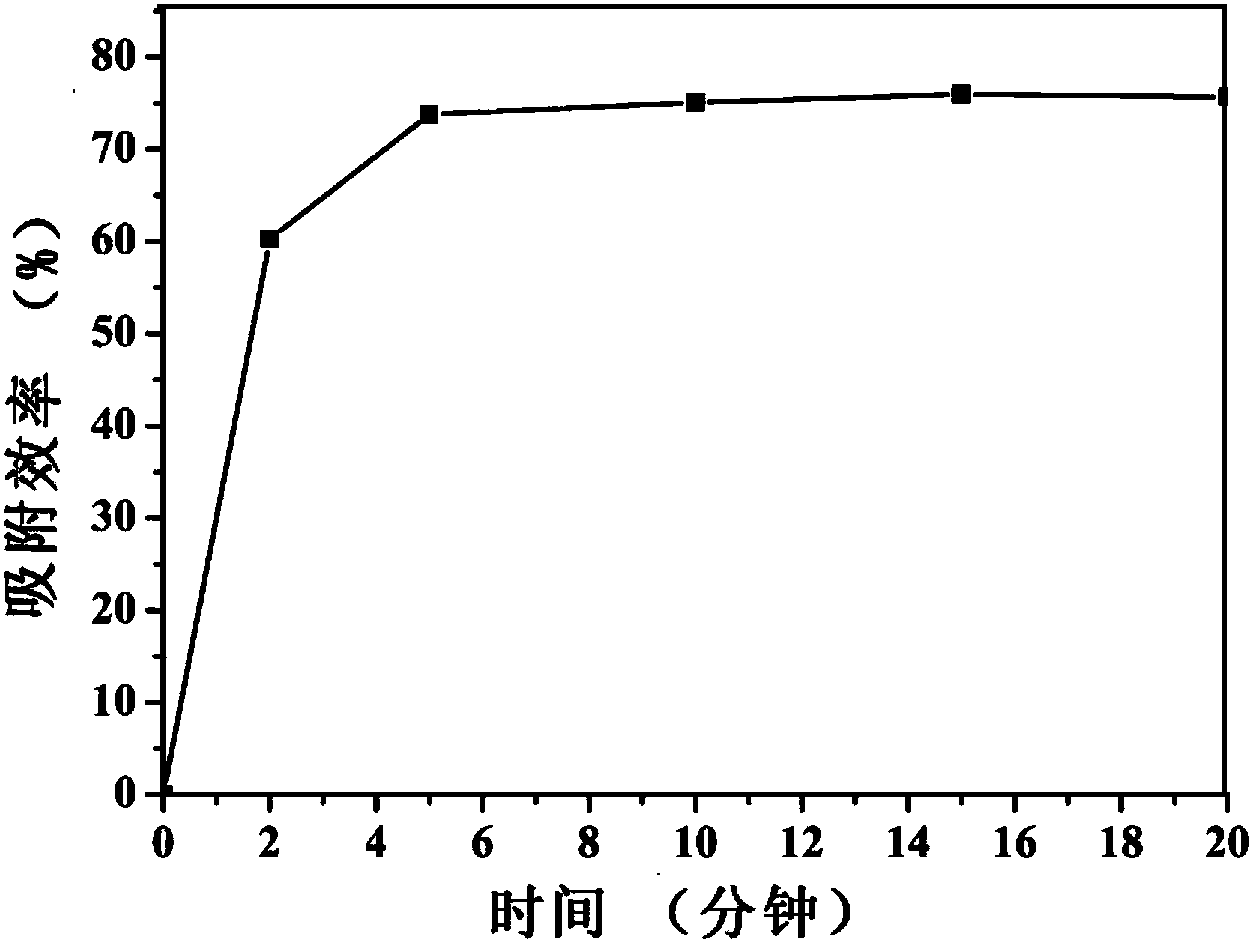

[0021] Graphite oxide was prepared by the classic hummer method, 1 gram of graphite oxide was dissolved in 100mL water, ultrasonically treated for two hours, the obtained dispersion was centrifuged at 4000rpm for 30 minutes, and the above graphene oxide suspension was collected, passed through Dilute to obtain a graphene oxide suspension with a concentration of 2 mg / ml, take 20 ml of the graphene oxide suspension, and add polyethyleneimine to form a mixed solution. The concentration of polyethyleneimine in the mixed solution is 2.5×10 -5 M, react the above mixed solution at 90°C without stirring for 6 hours to obtain a graphene hydrogel, wash the obtained graphene hydrogel with deionized water first to remove residual impurities, and then The graphene airgel was obtained by freeze-drying at 45° C. and a pressure of 0.02 mbar for 72 hours. Photos of the resulting product are shown in figure 1 , figure 1 It is shown that the prepared product is a macroscopic monolithic graphe...

Embodiment 2

[0023] Graphite oxide was prepared by the classic hummer method, 1 gram of graphite oxide was dissolved in 100mL water, ultrasonically treated for two hours, the obtained dispersion was centrifuged at 4000rpm for 30 minutes, and the above graphene oxide suspension was collected, passed through Dilute to obtain a graphene oxide suspension with a concentration of 2 mg / ml. Get graphene oxide suspension 200ml, add polyethyleneimine to form mixed solution, the concentration of polyethyleneimine in the mixed solution is 2.5 * 10 -5 M, react the above mixed solution at 90°C without stirring for 6 hours to obtain a graphene hydrogel, wash the obtained graphene hydrogel with deionized water first to remove residual impurities, and then The graphene airgel was obtained by freeze-drying at 45° C. and a pressure of 0.02 mbar for 72 hours. Photos of the resulting product are shown in Figure 4 , Figure 4 It is shown that the prepared product is a macroscopic bulk graphene airgel. It s...

Embodiment 3

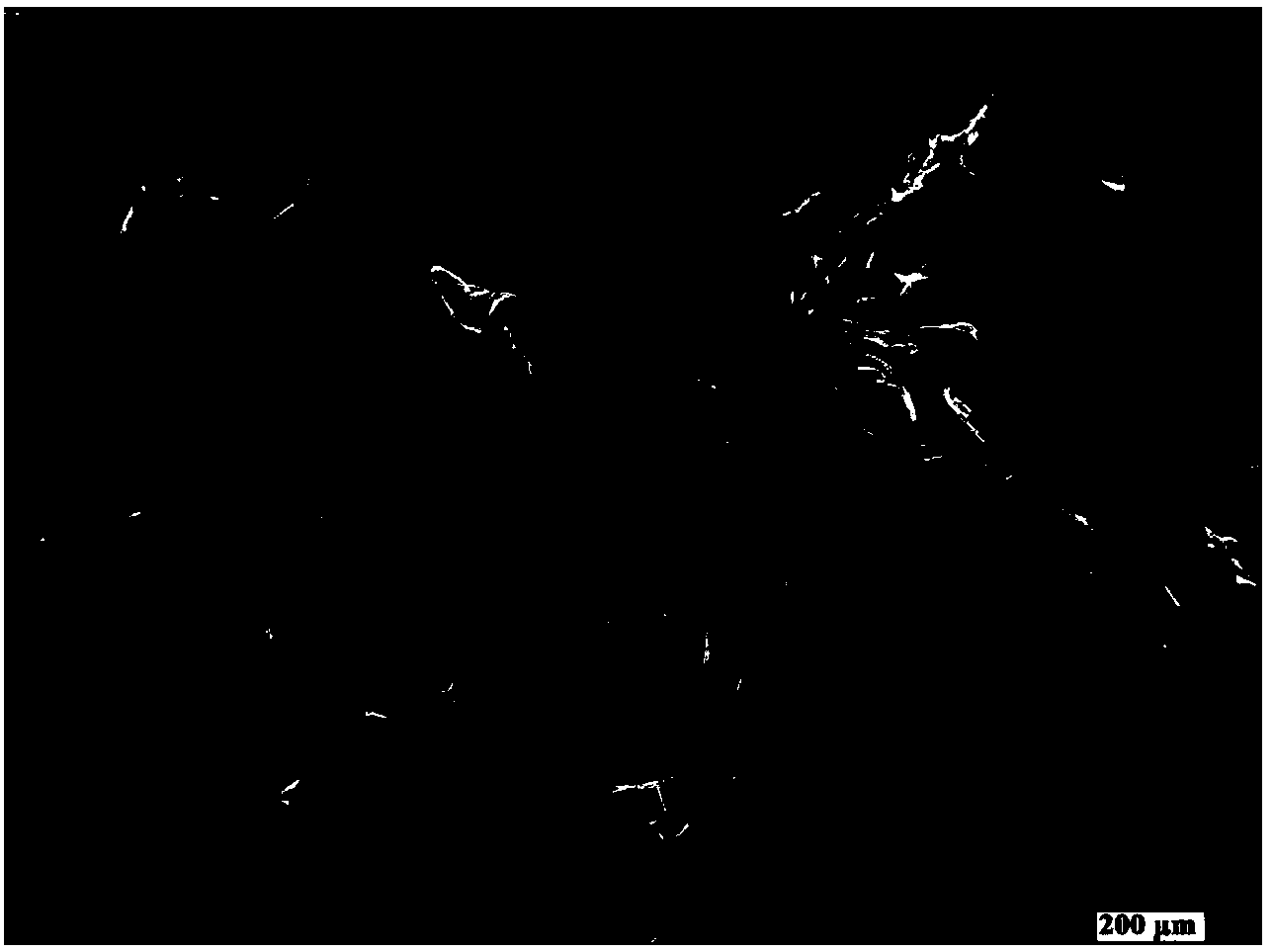

[0025] Graphite oxide was prepared by the classic hummer method, 1 gram of graphite oxide was dissolved in 100mL water, ultrasonically treated for two hours, the obtained dispersion was centrifuged at 4000rpm for 30 minutes, and the above graphene oxide suspension was collected, passed through Dilute to obtain a graphene oxide suspension with a concentration of 2mg / ml, take 20ml of the graphene oxide suspension, add polyethyleneimine, and the concentration of polyethyleneimine in the mixed solution is 2.5×10 -5 M, react the above mixed solution at 90°C without stirring for 30 minutes to obtain a graphene hydrogel, wash the obtained graphene hydrogel with deionized water to remove residual impurities, and then The graphene airgel was obtained by freeze-drying at 45° C. and a pressure of 0.02 mbar for 72 hours. The prepared product is a macroscopic monolithic graphene airgel. Scanning electron micrographs show that the overall morphology of the product is a three-dimensional ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com