Synthetic method of di-tert-butyldichlorosilane

A technology of di-tert-butyldichlorosilane and a synthesis method, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc. It can reduce the production cost, reduce the cost and reduce the energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

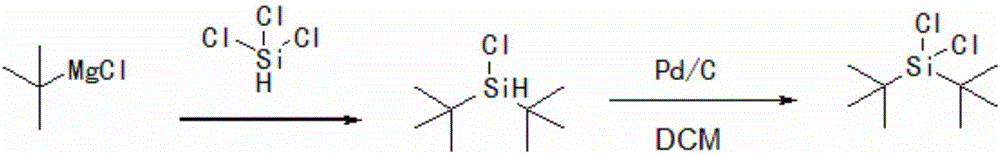

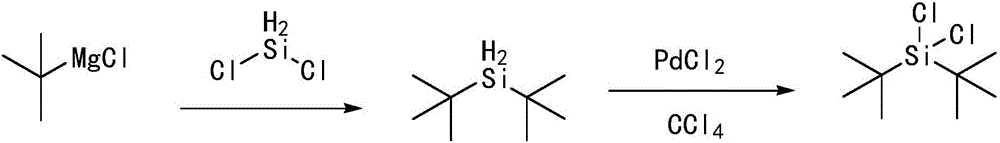

[0014] Di-tert-butyldichlorosilane synthetic method, said reaction chemical reaction formula is

[0015] ;

[0016] In the first step, under the protection of nitrogen, add 2.1 equivalents of magnesium chips and a certain amount of tetrahydrofuran into the reaction kettle, and drop a small amount of chloro-tert-butane to initiate the reaction. After the above reaction is initiated, control the temperature in the reaction kettle at 50°C Add a total of 1 equivalent of chloro-tert-butane dropwise. After the dropwise addition, keep warm at 50-52°C for 2 hours, and tetrahydrofuran is a Grignard reagent with a concentration of 3-5 moles per liter;

[0017] In the second step, a certain amount of tetrahydrofuran and 1.0 equivalent of trichlorohydrosilane are added to a dry reaction kettle to form a solution, and the ice salt water is lowered to -5°C in the kettle, and the Grignard reagent prepared above is added dropwise to control During the dropwise addition, the temperature in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com