An anti-seismic and anti-loosening back rivet bolt and a connection structure for curtain wall panels

An anti-loosening riveting and anti-loosening technology, applied in the direction of walls, shockproof, building components, etc., can solve the problems of cracking of the dies of the upsetting machine, increase in manufacturing cost, and difficulty in completing welding, etc., so as to reduce the installation cost and increase the The burden of manufacturing, the effect of saving installation labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

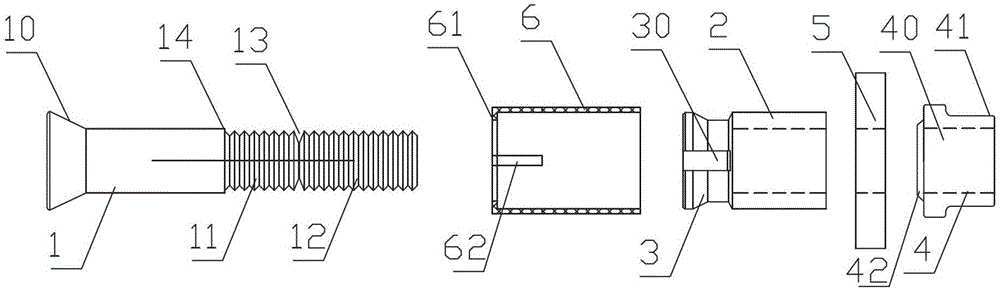

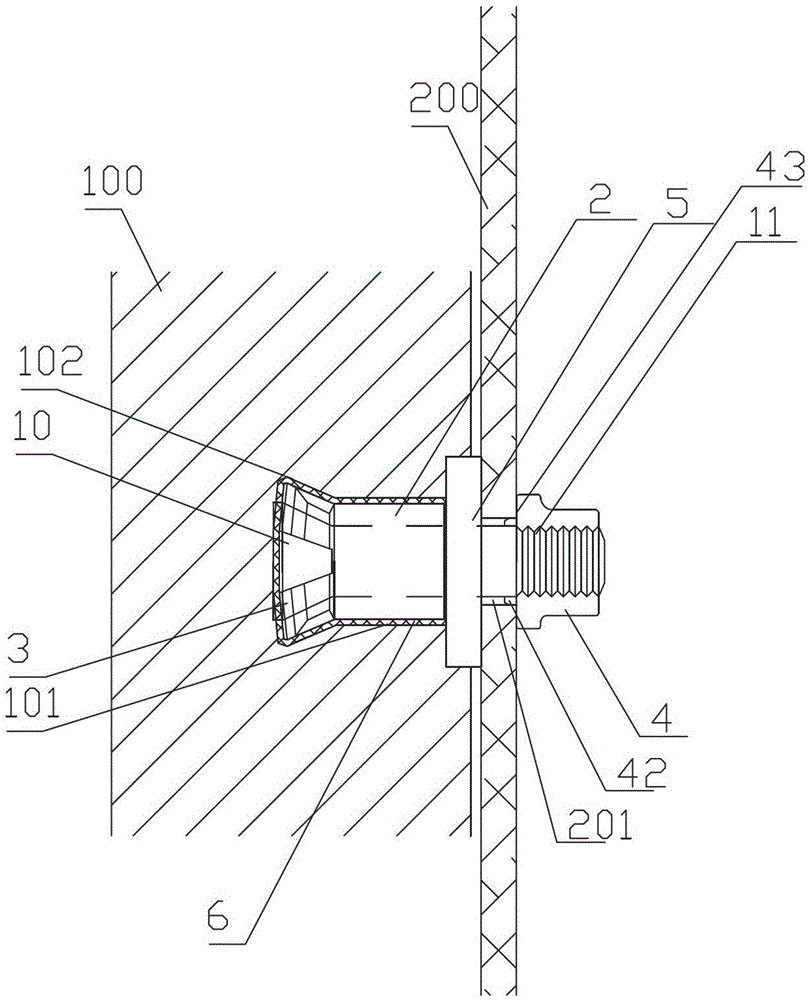

[0030] Refer to attached picture. An anti-shock and anti-loosening back riveting bolt provided by the present invention includes a metal rivet rod 1, a sleeve 2, and an expansion part 3. The head of the metal rivet rod 1 is an expansion head 10, and the expansion head 10 cooperates with the expansion part 3. It expands into the bottom undercut 102 of the connection hole 101 of the curtain wall panel 100 .

[0031] The metal rivet rod 1 includes an anti-loosening riveting section 11 corresponding to the outside of the connecting hole 101, and the surface of the anti-loosening and riveting section is provided with anti-stripping lines, such as concave lines, embossed lines, rings, annular grooves, etc. Make the surface of the anti-loosening riveting section 11 uneven. In addition to the anti-loosening and riveting section 11, there is a connection section 12 for connecting with the tool. There is a breaking position 13 between the connection section 12 and the anti-loosening an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com