Integrated storage tank supercharge and gasification sledge

A storage tank and pressurized pipe technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the needs of difficult to meet the needs of economic development, unfavorable enterprises to quickly resume production, basic and on-site requirements High problems, to achieve the effect of compact structure, lower installation cost and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

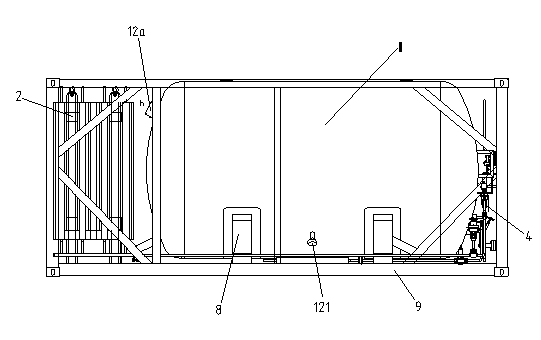

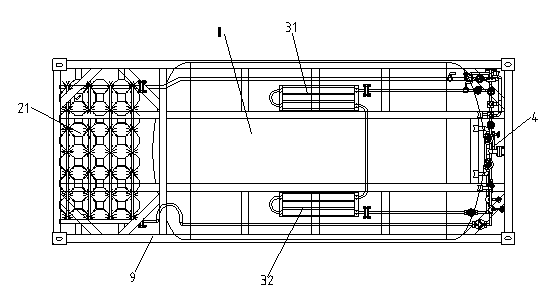

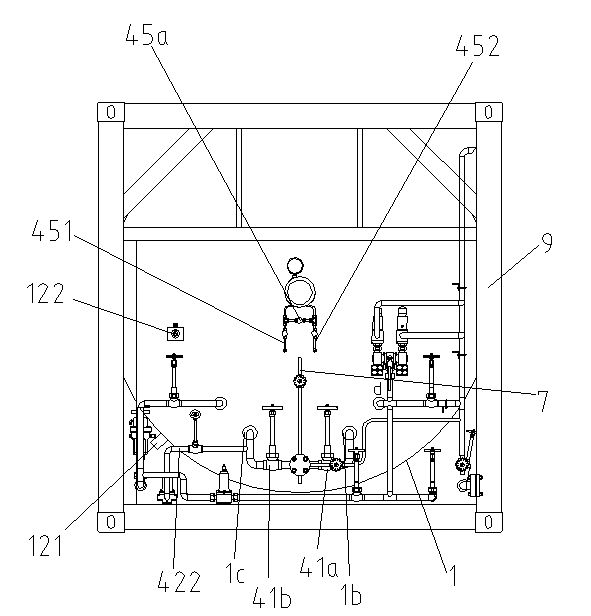

[0027] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

[0028] Figure 1 to Figure 6 Shown is a schematic structural diagram of the present invention.

[0029] The reference signs are: vacuum valve A1, vacuum valve A2, pressure gauge P, level gauge L, horizontal storage tank 1, vacuum insulation layer 1a, upper liquid inlet 1b, lower liquid inlet 1c, Inner container 11, tank shell 12, outer cylinder explosion-proof port 12a, vacuum port 121, vacuum port 122, pearl sand 13, vaporizer 2, air temperature vaporizer 21, heat exchange fin tube 22, connecting elbow 23, Upper self-supercharger 31, lower self-supercharger 32, pressure balance pipe 33, operating valve system 4, upper liquid inlet operation valve 41a, lower liquid inlet operation valve 41b, filling residual liquid discharge valve 41c, filling interface 411 , Upper liquid inlet pipe 412, lower liquid inlet pipe 413, pressurized gas phase operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com