Device and method for high-efficiency energy-saving combustion of low-heat value coal

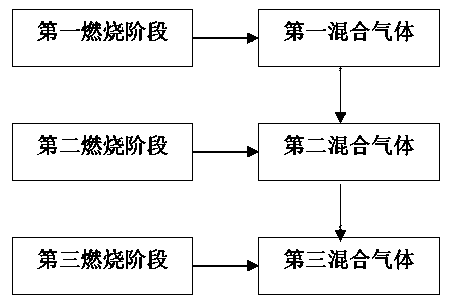

A high-efficiency energy-saving, combustion method technology, applied in the direction of combustion methods, combustion equipment, gaseous fuel and powder fuel combustion, etc., can solve the problems of insufficient combustion emissions, low volatile component content, low calorific value, etc., and achieve emission The effect of reduction, high energy efficiency and low flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, coal powder with a calorific value of 2500 calories is selected. The following experiments were performed.

[0024] In the first stage of combustion, the atomized pulverized coal (fineness is 90 mesh) is first sent to the pulverized coal burner through the first blower, and the first blower blows into the mixed gas with a volume content of 60% (air gas volume) at the same time. Ratio of 50%, water gas volume ratio of 50% mixed gas) and 40% air of 250 ℃ mixed gas, the mixed gas is burned in the combustion chamber. The sensor measures the combustion flame temperature at about 900°C. With the continuation of the combustion process, under the continuous air blowing action of the first blower, the combustion products of the first stage enter the solid combustion stage. In the solid combustion stage, the second blower blows into the mixed gas with a volume content of 20% (air gas The volume ratio is 50%, the water gas volume ratio is 50% mixed gas), the ...

Embodiment 3

[0032] In this embodiment, coal powder with a calorific value of 3000 calories is selected. The following experiments were performed.

[0033] In the first stage of combustion, the atomized pulverized coal (fineness is 100 mesh) is first sent to the pulverized coal burner through the first blower, and the first blower blows into the mixed gas with a volume content of 70% (air gas volume) at the same time. Ratio of 60%, water gas volume ratio of 40% mixed gas) and 30% air of 250 ℃ mixed gas, the mixed gas is burned in the combustion chamber. The temperature of the combustion flame measured by the sensor is about 920°C. With the continuation of the combustion process, under the continuous blowing action of the first blower, the combustion products of the first stage enter the solid combustion stage. In the solid combustion stage, the second blower blows into the mixed gas with a volume content of 15% (air gas The volume ratio is 60%, the water gas volume ratio is 40% mixed gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com