Horizontal-fin shell and tube heat exchanger

A finned tube and heat exchanger technology, which is applied in the field of high-efficiency horizontal shell and tube heat exchangers, can solve the problems of not considering the air flow distribution on the shell side, not considering the impact of the shell side fluid on the heat exchange tube bundle, serious flow short circuit, etc. , to achieve the effect of reasonable layout, improving compactness and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

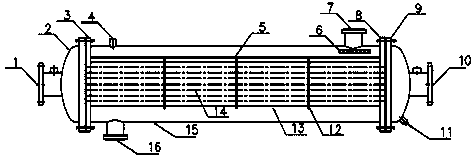

[0017] A kind of horizontal fin-tube shell-and-tube heat exchanger described in the embodiment of the present invention, such as figure 1 . The cylinder body 15 forms a closed space with the left tube plate 3 and the right tube plate 8, which becomes the shell side. The shell side inlet pipe 7 is arranged on the right side of the cylinder body 15 close to the tube plate position, and the shell side inlet pipe 7 on the left side of the cylinder body The shell side outlet pipe 16 is arranged at the symmetrical position. The heat exchange tube core is fastened by the heat exchange tube 14 parallel to the axis of the cylinder and the sleeve 13 perpendicular to the heat exchange tube through expansion joints to reduce contact thermal resistance and enhance heat transfer. The fins 13 are stamped and formed to form an expanded heat exchange surface on the outer surface of the heat exchange tube, and the expansion rate exceeds 20, which can greatly increase the heat transfer coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com