Textile defect detecting algorithm based on texture gradients

A texture gradient and defect detection technology, which is applied in computing, image data processing, computer parts, etc., can solve the problems of inaccurate detection of textile defects, heavy labor, and high cost, so as to enhance export competitiveness and application Broad, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

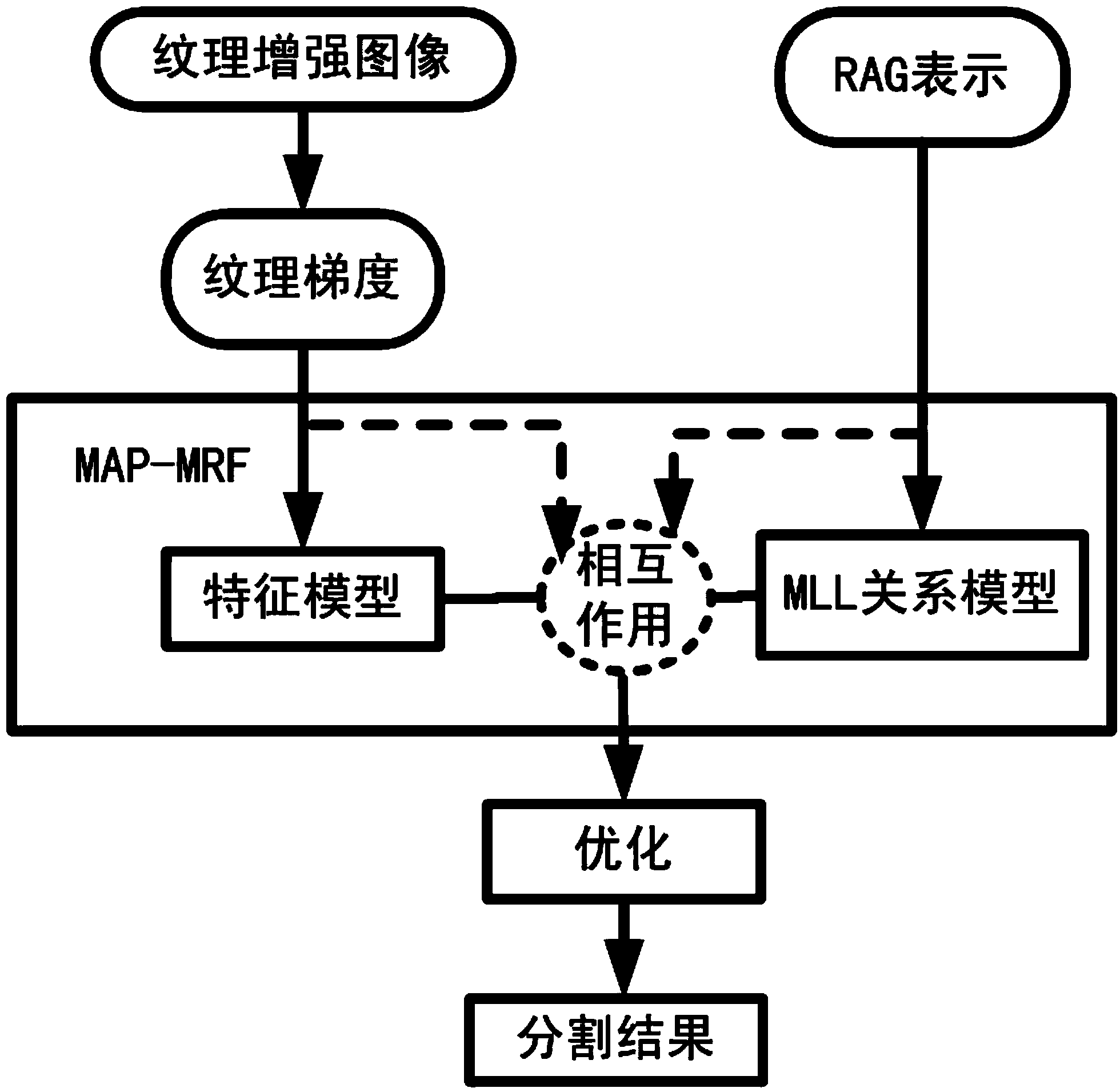

[0025] See attached figure 1 , a textile defect detection algorithm based on texture gradients, which includes the following steps:

[0026] Step 1: Use non-local mean filtering to enhance the texture of the texture image, eliminate noise and irrelevant details, enhance the expressiveness of texture details, and restore the original image structure;

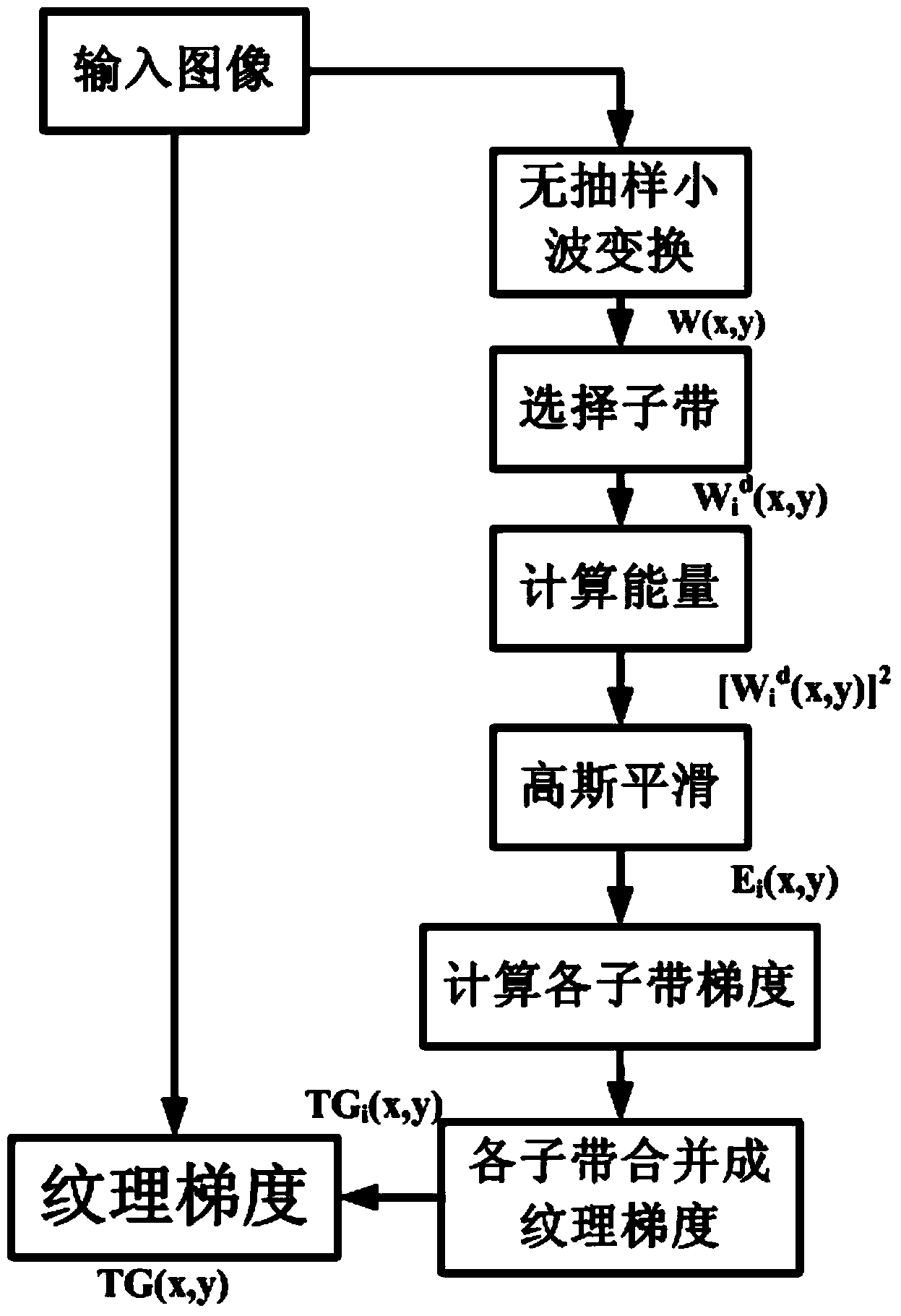

[0027] Step 2: Process the texture-enhanced textile image, and calculate the texture gradient image of the textile image;

[0028] Step 3: Construct the feature model of the texture gradient image;

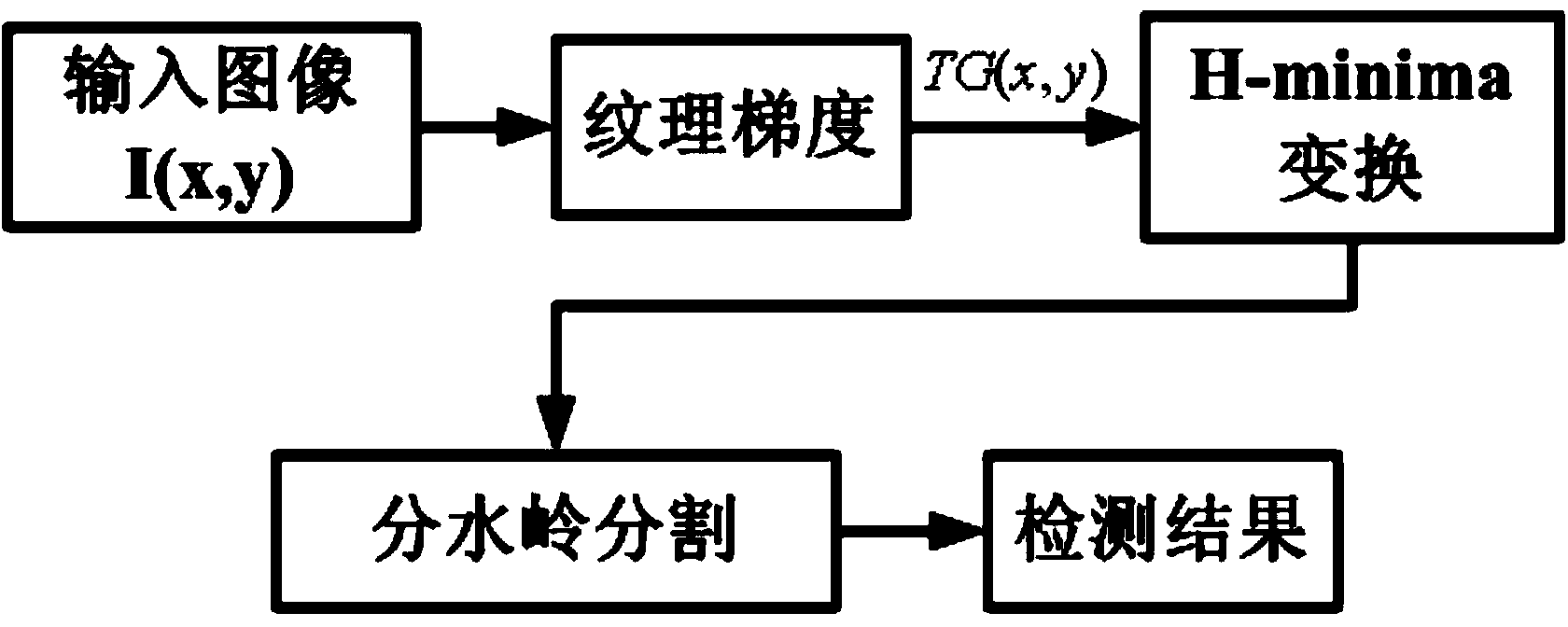

[0029] Step 4: Use the texture watershed calculation method to segment the texture gradient image, obtain the initial segmentation of the image, and obtain a uniform region with the same characteristics, and then construct a RAG (RAG: region adjacency graph, region adjacency graph) to represent the MLL relationship model ( multi-level logistic model, each region in the multi-level logic model), and use the MLL relationship model to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com